________________________________________________________________________________

Repair of Case 1194,1294 Tractor 12-speed Synchromesh transmission

Disassembly Operations

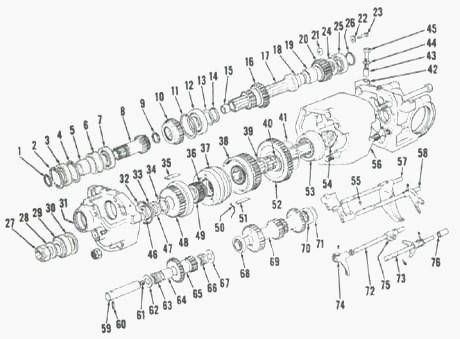

Fig.18. Case 1194, 1394, 1490, 1294, 1594 Tractor 12-speed

synchromesh transmission

1.Snap ring, 2.Snap ring, 3.Bearing, 4.Snap ring, 5.Inner sparer,

6.Outer spacer, 7.Bearing, 8.Input gear, 9.Sealing ring, 10.Slow/normal

sliding gear, 11.Snap ring, 12.Bearing, 13.Spacer, 14.Snap ring,

15.Bushing, 16.High/law sliding gear, 17.Input shaft, 15.Bushing

surface, 19.Bushing, 20.Reverse idler gear, 21.Retaining washer, 22.Tab

washer, 23.Bolt, 24.Thrust washer, 25.Bearing, 26.Snap ring, 27.Locknut,

28.Wisher, 29.Bearing, 30.Spacer, 31.Front end housing, 32.Snap ring,

33.Shims, 34.Thrust washer, 35.Bearing pad, 36.Snap ring,

37.Synchronizer, 38.Second gear, 39.Retaining washer, 40.Split rings,

41.Shim, 42.Rear end housing, 43.Bushing, 44.Shim, 45.Mounting bolt,

46.Shoulder spacer, 47.Washer, 48.Third gear, 49.Front synchronizer

gear, 50.Synchronizer spring, 51.Bearing pad, 52.First/reverse sliding

gear, 53.Bearing, 54.Pinion shaft, 55.Shift interlock, 56.Center

housing, 57.Second/third shift rod, 58.First/reverse shift rod, 59.Idler

shaft, 60.Roll pin, 61 Plug, 62.Thrust washer, 63.Bearing, 64.Spacer,

65.Idler gear, 66.Bearing, 67.Thrust washer, 68.Bearing,

69.Countershaft, 70.Bearing, 71.Shim, 72.Slow/normal shift rod,

73.High/low shift rod, 74.Shift fork, 75.Selector jaw, 76.Sleeve

Place transmission in a suitable transmission support stand, then remove

roll pins from slow/normal shift fork (74) and selector jaw (75). Push

slow/normal shift rod (72) rearward just far enough to remove detent

ball and spring. Remove shift rod, selector jaw and shift fork.

Remove high/low shift fork, sleeve, detent ball and spring and shift rod

(73). Remove roll pins from shift fork and selector jaw on second/third

shift rod (57) and move rod toward rear of transmission just enough to

remove detent ball and spring. Remove shift interlock plug (55).

Noting pinion nut (27) has left-hand threads, remove nut (27), washer

(28) and bearing cone (29) from pinion shaft (54). Remove stud bolt

nuts, then separate and support front end housing (31) approximately 40

mm (1.5 inches) from transmission center housing (56).

Push first/reverse shift rod (58) rearward just enough to remove detent

ball and spring. Lift front end housing (31) off Case 1194, 1294 Tractor

transmission center housing (56). Remove slow/normal sliding gear (10)

from inside front end housing.

Remove roll pin (60) and remove idler shaft (59). Remove snap ring (1)

from input gear (8) and snap ring (2) from front end housing (31).

Carefully remove input gear assembly out of front end housing. Do not

use force as damage to bearings may result. Remove idler gear (65) and

both thrust washers (62 and 67).

Remove bearings (63 and 66) and spacer (64) from inside idler gear (65).

Remove input gear bearing cup and outer spacer (6) from front end

housing. Remove remaining bearing cups, spacer, bearings and snap rings

as necessary.

Remove stud bolts. Remove center housing (56) by rotating center housing

towards countershaft to gain clearance, then lift housing over shaft and

gear assemblies.

Remove countershaft (69) from rear end housing (42). Remove retaining

bolt (23), remove high/low shift fork from sliding gear (16), and remove

input shaft assembly (17) from rear end housing. Use care not to lose

retainer (21).

Remove snap ring (26) and press rear bearing (25), thrust washer (24)

and reverse idler gear (20) off together. Move snap ring (14) away from

bearing (12) and press bearing and spacer (13) off input shaft (17).

Remove snap ring (14) and high/low sliding gear (16). Remove bushing

(15) from inside input shaft.

Remove second/third shift fork from synchronizer (37). Remove shoulder

spacer (46), shims (33), spacer (47) and third gear thrust washer (34).

Remove third gear (48) and the six bearing pads (35). Remove

synchronizer (37) and front synchronizer gear (49). Remove snap ring

(36) and gear synchronizer gear (not shown).

Remove second gear (38), the six bearing pads (51), split ring retainer

washer (39) and split rings (40). Remove first/reverse sliding gear (52)

and shift rod assembly together.

If pinion shaft (54) is to be renewed, mark differential bearing cap

positions and remove differential assembly. Remove pinion shaft rearward

from housing.

Inspection

Clean and inspect all parts. Examine bearings and bushings for wear or

damage and renew as necessary. If gear teeth show excessive wear or

irregular wear pattern, gear should be renewed along with its mating

gear.

Examine synchronizer friction surfaces and the synchronizer pads (35 and

51) for wear. Slight looseness of pads in synchronizer is normal and the

pads should slide easily into their grooves with no binding. No attempt

should be made to disassemble synchronizer assembly as individual

service parts are not available.

Fig.19

Examine fit of detent balls in grooves of shifter rails. Shift rail

grooves should have straight 60 degree sides and detent ball must not

contact bottom of groove. Check all thrust washers and spacers for

excessive wear or damage and renew as necessary.

If pinion shaft, bearings, end housings or center housing are renewed,

pinion shaft protrusion must be set before reassembling Case IH 1194,

1294 Tractor transmission.

Pinion shaft assembly

Install:

- pinion shaft and rear bearing sliding gear (16) on input shaft with

larger diameter gear toward rear end of shaft. Heat front bearing (12)

to 120°C (250°F) maximum, then install snap ring (14), spacer (13) and

bearing on shaft. Note that bearing must be installed with side stamped

with bearing numbers towards front end of shaft.

Press new bushing (19) into reverse idler gear (20), then install gear

onto input shaft with beveled edge of gear teeth towards front of shaft.

- thrust washer (24) with flat side towards idler gear. Heat rear

bearing (25) to 120°F (250°F) maximum, then install bearing and snap

ring (26).

PPosition shaft assembly on rear housing and install retaining washer

(21), tab washer (22) and bolt (23). Tighten bolt to 11 N-m (8 ft.-lbs.)

torque, then bend tab washer against bolt head.

Input shaft assembly

Install:

- new bushing (15) into front end of input shaft (17). Place high/low

into rear housing. Position first/reverse shift fork into slot in

sliding gear (52), then install gear over

pinion shaft. Make certain shift rod enters hole nearest input shaft

retaining washer.

- split rings (40) and retaining washer (39).

- second gear (38) with synchronizer ring towards front end of shaft.

Lightly coat bearing pads (51) with grease, then install pads in pinion

shaft splines under second

gear.

- rear synchronizer gear so end of gear with alignment marks is towards

second gear.

- snap ring (36), align marks of rear synchronizer gear with marks on

front synchronizer gear.

- front gear (49) with slotted end of gear towards front of shaft.

- synchronizer (37).

- third gear (48) with synchronizer ring towards synchronizer. Apply

small amount of grease to bearing pads (35), then install pads behind

third gear.

- thrust washer (34) and fiat spacer (47). Do not install shims (33) or

shoulder spacer (46) at this time.

Countershaft assembly

Heat front and rear hearings (68 and 70) to 120°C (250°F) maximum, then

install on countershaft (69).

To adjust end play, remove a shim 0.25 mm (0.010 inch) in thickness from

original shim pack (71).

Install:

- remainder of shims and bearing cup in rear housing.

- front bearing cup in bore of front housing. Position countershaft on

rear housing.

- center housing, stud bolts and front housing and tighten stud bolt

nuts to 95 Nm (70 ft.-lbs.) torque. Mount a dial indicator so probe

contacts rear gear of countershaft.

Move shaft up and down and measure end play. Disassemble housings and

countershaft. Remove rear bearing cup and shims. Subtract 0.076 mm

(0.003 inch) from

end play measurement. The result is thickness of shims that must be

added to original shim pack to obtain specified end play of 0.076 mm

(0.003 inch).

- required thickness of shims and reinstall bearing cup. Position

countershaft on rear housing.

Center and front housing assemblies

To install:

- center housing (56), place second/third gear selector fork into groove

on synchronizer (37). Put high/low selector fork into groove on sliding

gear (16).

- center housing turning the housing to clear countershaft gears. Apply

Loctite 242 to stud bolt threads, then install stud bolts into rear

housing and tighten to 122 N-m

(90 ft.-lbs.) torque. Heat bearing (7) to 120°C (250°F) maximum, then

install on input gear (8). Be sure side of bearing stamped with bearing

numbers is towards

splined end of gear.

- inner spacer (5) on input gear.

- snap ring (4), bearing (3) and snap ring (2) in front housing (31).

- outer spacer (6) and outer bearing race for roller bearing in front

housing. Assemble bearings (63 and 66) and spacer (64) in range idler

gear (65). Use a depth

micrometer to measure distance needle bearing cage is below free of

idler gear. The distance must be 0.25-1.27 mm (0.010-0.050 inch). If

distance is not within the

specified range, check for worn needle bearings. Renew spacer if spacer

length is less than 42.545 mm (1.675 inches).

- assembled range idler gear and thrust washer (62 and 67) in front

housing with larger gear towards front of the housing.

- input gear assembly in front housing and install snap ring. Clean oil

passage in idler gear shaft (59), apply Loctite 242 to threads of plug

(61) and install plug in shaft.

Align roll pin hole in idler shaft and front housing.

- install shaft through idler gear and roll pin. Assemble snap ring

(32), spacer (30) and pinion shaft front bearing cup into bore in front

housing.

- front housing assembly and support housing approximately 40 mm (l'/a

inches) above center housing. Place slow/normal sliding gear (10) on

rear input shaft (17)

with selector fork groove towards input gear. Remove spacers, then lower

front housing until first/reverse shift rod (58) enters hole in front

housing.

- detent ball and spring using tool while joining front housing and

center housing.

- new locknuts on housing studs and tighten to 95 N-m (70 ft.-lbs.)

torque.

Shift rods and detents

Install:

- high/low shift rod (73) and spacer (76). Install detent spring and

ball using tool.

- roll pin in shift fork.

- slow/normal shift rod (72), shift fork (74), spacer and selector

jaw(75).

- detent spring and ball using assembly tool, then install roll pins in

fork and selector jaw.

- second/third shift rod making certain end with neutral start switch

groove is toward rear of transmission. Push rod through shift fork

slightly.

- selector jaw with flat side toward first/reverse selector jaw.

- shift interlock plug (55) and detent ball and spring.

Engage third gear and install roll pin in second/third selector jaw.

Engage second gear and install roll pin in second/third shift fork.

Pinion shaft bearing preload

Install:

- original shims (33) removed during disassembly plus an additional 0.25

mm (0.010 inch) thick shim.

- shoulder washer (46) with flat side against shims (33).

- bearing cone (29), washer (28) and nut (27). Note that nut has

left-hand threads and tighten to 270 N-m (200 ft.-lbs.) torque. Mark

differential bearing caps and

remove differential assembly if not already removed. Mount dial

indicator so probe contacts end of pinion shaft, then measure and note

amount of pinion shaft end

play.

Remove nut (27), washer (28), bearing (29) and shoulder washer (46).

Remove thickness of shims (33) 0.05 mm (0.002 inch) greater than amount

of measured end

play to obtain specified bearing preload of 0.05 mm (0.002 inch).

Reinstall spacer, bearing, washer and nut. Tighten nut to 270 N-m (200

ft.-lbs.) torque. Reinstall

differential assembly and adjust backlash.

Shift transmission and range section through all gears and check to be

certain all gears and detents work properly.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| CASE IH TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| CASE IH FRONT END LOADERS SPECS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

CASE IH SPECS

CASE IH SPECS J.I. CASE SPECS

J.I. CASE SPECS PROBLEMS

PROBLEMS LOADERS

LOADERS FARMALL 110A

FARMALL 110A FARMALL 120A

FARMALL 120A FARMALL 30C

FARMALL 30C FARMALL 75C

FARMALL 75C MAGNUM 280

MAGNUM 280 580E Backhoe

580E Backhoe 580L Backhoe

580L Backhoe 580N Backhoe

580N Backhoe 580 Super L

580 Super L 580SM Backhoe

580SM Backhoe 580SLE Backhoe

580SLE Backhoe 580SN Backhoe

580SN Backhoe 580M Backhoe

580M Backhoe 580 Super E

580 Super E 580ST Backhoe

580ST Backhoe MAGNUM 310

MAGNUM 310 MAGNUM 340

MAGNUM 340 MAXXUM 110CVX

MAXXUM 110CVX MAXXUM 120CVX

MAXXUM 120CVX MAXXUM 125

MAXXUM 125 1394

1394 1455XL

1455XL 1494

1494 1594

1594 3230

3230 4210

4210 585XL

585XL 633

633 695XL

695XL 733

733 MX110

MX110 MX135

MX135 MX150

MX150 MXU110

MXU110 MXU135

MXU135 PUMA 175CVX

PUMA 175CVX PUMA 185CVX

PUMA 185CVX PUMA 200CVX

PUMA 200CVX PUMA 240CVX

PUMA 240CVX OPTUM 300

OPTUM 300 FARMALL 50B

FARMALL 50B FARMALL 95U

FARMALL 95U FARMALL 125A

FARMALL 125A PUMA 150

PUMA 150 PUMA 165

PUMA 165 MAGNUM 210

MAGNUM 210 MX 170

MX 170 MAXXUM 150

MAXXUM 150 OPTUM 270

OPTUM 270 MAGNUM 315

MAGNUM 315 FARMALL 70

FARMALL 70 FARMALL 75N

FARMALL 75N FARMALL 95C

FARMALL 95C FARMALL 105N

FARMALL 105N FARMALL 30B

FARMALL 30B L103 Loader

L103 Loader L104 Loader

L104 Loader L105 Loader

L105 Loader L106 Loader

L106 Loader L107 Loader

L107 Loader L108 Loader

L108 Loader L130 Loader

L130 Loader L160 Loader

L160 Loader L300 Loader

L300 Loader L340 Loader

L340 Loader L350 Loader

L350 Loader L360 Loader

L360 Loader L530 Loader

L530 Loader L540 Loader

L540 Loader L545 Loader

L545 Loader L550 Loader

L550 Loader L555 Loader

L555 Loader L560 Loader

L560 Loader L565 Loader

L565 Loader L570 Loader

L570 Loader L575 Loader

L575 Loader L720 Loader

L720 Loader L730 Loader

L730 Loader L735 Loader

L735 Loader L740 Loader

L740 Loader LRZ 95

LRZ 95 LRZ 100

LRZ 100 LRZ 120

LRZ 120 LRZ 130

LRZ 130 LRZ 150

LRZ 150 L745 Loader

L745 Loader L750 Loader

L750 Loader L755 Loader

L755 Loader L760 Loader

L760 Loader L765 Loader

L765 Loader L770 Loader

L770 Loader L775 Loader

L775 Loader L780 Loader

L780 Loader L785 Loader

L785 Loader L795 Loader

L795 Loader 90 Loader

90 Loader 890 Loader

890 Loader 2200 Loader

2200 Loader 2250 Loader

2250 Loader LX156 Loader

LX156 Loader