________________________________________________________________________________

Case 1390, 1690 Tractor Power Shift Transmission – control valve

Power shift Case 1690, 1194, 1290, 1390, 1190 Tractor transmission

consists of a three forward, one reverse mechanical gear section coupled

with a four-speed, hydraulic power shift section providing twelve

forward and four reverse speed selections.

Front four-speed planetary section is hydraulically controlled and

changes between any of the ratios can be made while tractor is in motion

without use of transmission clutch. Gear (range) speeds are selected

manually and trans-mission clutch must be used.

Power shift control valve

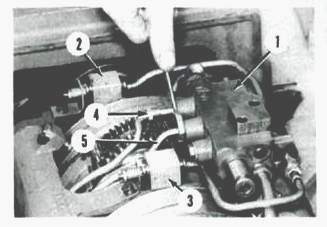

Fig.32. Identify power shift front sequence valve (2) and rear

sequence valve (3) prior to removal as valve are not Interchangeable

Flow restrictors are located in front end rear planetary brake pressure

lines (4 and 5).

Power shift control valve spool and body (8) are serviced as an assembly

only. However, relief valve spring (2) and spool (3) are available

separately.

To remove control valve, first remove platform or cab, if so equipped.

Remove fuel tanks. Disconnect wiring harness to rear of tractor and

disconnect neutral start switch wires. Remove range and power shift

selector assemblies from transmission cover.

Disconnect hydraulic lines and control linkage from remote valve. Remove

mounting bolts and remove remote valve assembly. Remove transmission

cover mounting bolts and remove wedge and shim from front of cover. Use

a hoist to lift transmission cover from main frame.

Disconnect hydraulic lines from control valve (1). Mark sequence valves

(2 and 3) so they can be reinstalled in their original positions, then

remove both valves. Remove control valve mounting bolts and remove valve

assembly.

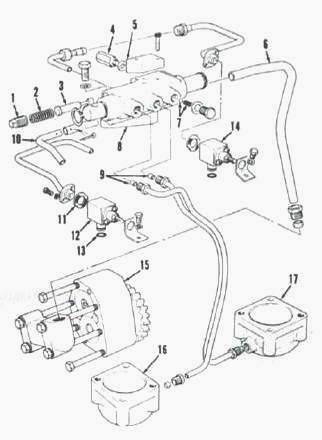

Fig.33. Power shift control valve, sequence valves and related

oil lines

1.Adjusting screw, 2.Spring, 3.Relief valve plunger, 4.Plug,

5.Restrictor plate, 6.Oil supply pipe, 7.Detent spring & ball, 8.Control

valve body & spool, 9.Restrictors, 10.Lubrication tube, 11.Sealing

washer, 12.Sequence valve front, 13."O" ring, 14.Sequence valve rear,

15.Power shift hydraulic pump, 16.Planetary brake cylinder front,

17.Planetary brake cylinder rear

To disassemble valve for inspection, remove seal wire from relief valve

adjusting screw (1). Remove adjusting screw while noting number of turns

required to remove screw for use in reassembly.

Remove spring (2) and relief valve spool (3). Remove plug and detent

spring and ball (7). Remove snap ring from valve spool, then withdraw

spool from valve body. Remove test port plug (4) and restrictor plate

(5).

Inspect all parts for wear or scoring. Be sure control valve spool and

bore are free of scoring or other damage. Reassemble valve by reversing

disassembly procedure. Lubricate all parts during reassembly.

Setting control valve pressure

Reinstall control valve and tighten mounting bolts to 34 N-m (25

ft.-lbs.) torque. Install front and rear sequence valves. Move control

valve spool fully forward and remove plug (4) from control valve test

port.

Install Case IH 1390, 1690 Tractor transmission cover and remote valve

assembly. Do not install power shift selector lever at this time. Remove

test port plug from right side of transmission cover. Install special

adapter and a 0-1000 kPa (0-150 psi) pressure gage (1) through opening

in cover and into test port.

Use a remote fuel supply to operate tractor. Start engine and run to

bring transmission fluid temperature to approximately 45 °C (115°F).

Transmission housing must be warm to the touch. With engine running at

1500 rpm, pressure reading should be 350-560 kPa (77-81 psi) or 600-625

kPa (87-91 psi).

To adjust pressure, insert a screwdriver through power shift selector

opening in transmission cover and turn relief valve adjusting screw

clockwise to increase pressure or counterclockwise to reduce pressure.

Stop engine and remove manifold and gage. Remove remote valve and

transmission cover. Install plug in control valve test port and install

a lock wire in relief valve adjusting screw to secure adjustment.

Reassemble Case 1390, 1690 Tractor by reversing disassembly procedure

while noting the following special instructions. Tighten remote valve

mounting bolts to 47-57 N-m (35-40 ft.- lbs.) torque.

Tighten transmission cover % inch mounting bolts to 102-122 N-m (75-90

ft.-lbs.) torque and % inch mounting bolts to 165-200 N-m (120-130

ft.-lbs.) torque. Tighten range and power shift selector housing

mounting bolts to 23-28 N-m (17-20 ft.-lbs.) torque.

Sequence valves

The sequence valves (2 and 3) control release timing of front and rear

planetary clutch units. Front and rear sequence valves are mechanically

identical, however, they have different pressure settings.

Therefore, be sure valves are properly marked before removal so they can

be reinstalled in their original positions. Front sequence valve

controls release of front planetary clutch, while rear sequence valve

controls release of rear planetary clutch.

To remove sequence valves, it is first necessary to remove Case IH 1390,

1690 transmission cover. Sequence valves are serviced as a complete

assembly only, but valves may be disassembled for cleaning and

inspection. It is recommended adjustment screw setting not be disturbed

during disassembly.

All new sequence valves obtained through parts are adjusted at factory

to rear sequence valve pressure setting (which is lower than front

setting). If a new sequence valve is to be installed in front position,

increase factory setting by turning adjusting screw clockwise two full

turns.

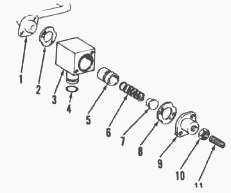

Fig.34. Power shift sequence valve. Adjustment screw (11)

setting should not be changed unless valve pressure is to be reset

1.Pressure line, 2.Ganket, 3.Valves body, 4."O" ring, 5.Piston,

6.Spring, 7.Sprint neat, 8.Gasket, 9.End cap, 10.Locknut, 11.Adjusting

screw

Pressure setting of sequence valves can be checked and adjusted using a

suitable hand pressure pump and a 0-400 kPa (0-60 psi) pressure gage.

Remove hydraulic pressure line from valve, block orifice in piston with

tape and reinstall pressure pipe.

Connect sequence valve to hand pressure pump and pressure gage. Operate

hand pump slowly and note pressure reading at point pressure makes a

rapid drop indicating valve opened. Adjust screw (11) until pressure

release point is 210-220 kPa (32-33 psi).

If valve is to be installed in rear position, tighten jam nut to secure

adjusting screw at this setting. If valve is to be installed in front

position, turn screw clockwise an additional two turns and secure with

jam nut. Remove tape from piston orifice, reassemble valve and install

in proper position.

Power shift hydraulic pump

The power shift hydraulic pump is mounted on lower right-hand corner of

range gearbox front cover. The pump is gear driven from reverse gear of

range Case 1390, 1690 Tractor transmission.

To remove pump, first separate power shift transmission from main frame.

Remove manifold and pump mounting bolts, then remove pump assembly from

rear side of housing.

Use a suitable puller to remove pump drive gear. Remove Woodruff key,

then separate pump rotor assembly from pump body.

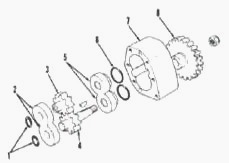

Fig.35. Power shift hydraulic pump

1."O" rings, 2.Bushings, 3.Idler gear, 4.Driven gear, 5.Bushing, 6."O"

rings, 7.Pump body, 8.Drive gear

Inspect all parts for wear or damage. Pump rotors and bearings are

serviced as a complete set. Renew all "O" rings.

When reassembling, make sure sides of bearings with oil grooves are

against gears. Lubricate all parts with clean oil during assembly.

Install drive gear using a new locknut and tighten nut to 73-86 N-m

(54-64 ft.-lbs.) torque.

Reinstall pump and manifold using new "O" rings in oil ports. Tighten

mounting bolts to 23-27 Nm (17-20 ft.-lbs.) torque.

________________________________________________________________________________

________________________________________________________________________________________

| CASE IH TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| CASE IH FRONT END LOADERS SPECS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

CASE IH SPECS

CASE IH SPECS J.I. CASE SPECS

J.I. CASE SPECS PROBLEMS

PROBLEMS LOADERS

LOADERS FARMALL 110A

FARMALL 110A FARMALL 120A

FARMALL 120A FARMALL 30C

FARMALL 30C FARMALL 75C

FARMALL 75C MAGNUM 280

MAGNUM 280 580E Backhoe

580E Backhoe 580L Backhoe

580L Backhoe 580N Backhoe

580N Backhoe 580 Super L

580 Super L 580SM Backhoe

580SM Backhoe 580SLE Backhoe

580SLE Backhoe 580SN Backhoe

580SN Backhoe 580M Backhoe

580M Backhoe 580 Super E

580 Super E 580ST Backhoe

580ST Backhoe MAGNUM 310

MAGNUM 310 MAGNUM 340

MAGNUM 340 MAXXUM 110CVX

MAXXUM 110CVX MAXXUM 120CVX

MAXXUM 120CVX MAXXUM 125

MAXXUM 125 1394

1394 1455XL

1455XL 1494

1494 1594

1594 3230

3230 4210

4210 585XL

585XL 633

633 695XL

695XL 733

733 MX110

MX110 MX135

MX135 MX150

MX150 MXU110

MXU110 MXU135

MXU135 PUMA 175CVX

PUMA 175CVX PUMA 185CVX

PUMA 185CVX PUMA 200CVX

PUMA 200CVX PUMA 240CVX

PUMA 240CVX OPTUM 300

OPTUM 300 FARMALL 50B

FARMALL 50B FARMALL 95U

FARMALL 95U FARMALL 125A

FARMALL 125A PUMA 150

PUMA 150 PUMA 165

PUMA 165 MAGNUM 210

MAGNUM 210 MX 170

MX 170 MAXXUM 150

MAXXUM 150 OPTUM 270

OPTUM 270 MAGNUM 315

MAGNUM 315 FARMALL 70

FARMALL 70 FARMALL 75N

FARMALL 75N FARMALL 95C

FARMALL 95C FARMALL 105N

FARMALL 105N FARMALL 30B

FARMALL 30B L103 Loader

L103 Loader L104 Loader

L104 Loader L105 Loader

L105 Loader L106 Loader

L106 Loader L107 Loader

L107 Loader L108 Loader

L108 Loader L130 Loader

L130 Loader L160 Loader

L160 Loader L300 Loader

L300 Loader L340 Loader

L340 Loader L350 Loader

L350 Loader L360 Loader

L360 Loader L530 Loader

L530 Loader L540 Loader

L540 Loader L545 Loader

L545 Loader L550 Loader

L550 Loader L555 Loader

L555 Loader L560 Loader

L560 Loader L565 Loader

L565 Loader L570 Loader

L570 Loader L575 Loader

L575 Loader L720 Loader

L720 Loader L730 Loader

L730 Loader L735 Loader

L735 Loader L740 Loader

L740 Loader LRZ 95

LRZ 95 LRZ 100

LRZ 100 LRZ 120

LRZ 120 LRZ 130

LRZ 130 LRZ 150

LRZ 150 L745 Loader

L745 Loader L750 Loader

L750 Loader L755 Loader

L755 Loader L760 Loader

L760 Loader L765 Loader

L765 Loader L770 Loader

L770 Loader L775 Loader

L775 Loader L780 Loader

L780 Loader L785 Loader

L785 Loader L795 Loader

L795 Loader 90 Loader

90 Loader 890 Loader

890 Loader 2200 Loader

2200 Loader 2250 Loader

2250 Loader LX156 Loader

LX156 Loader