________________________________________________________________________________

Case 585, 885 Tractor Range transmission

The Case 685, 485, 585, 385, 885 tractor range transmission is located

in the front portion of the tractor rear frame.

The range tractor transmission is equipped with Hi (direct drive), Lo

(under drive), neutral and reverse.

On tractor models equipped with Forward-Reverse transmission, range

transmission uses only Hi, Lo and neutral as reverse is provided by the

Forward-Reverse unit.

The light duty band and drum type transmission park brake is located in

the range tractor transmission. The heavy duty park brake is located on

the differential ring gear.

To remove the range transmission, tractor rear main frame (range

section) must be separated from speed gearbox and the differential and

the hydraulic lift housing removed.

Overhaul

With the engine and speed gearbox assembly separated from the range

section, remove hydraulic lift housing. Remove the differential

assembly.

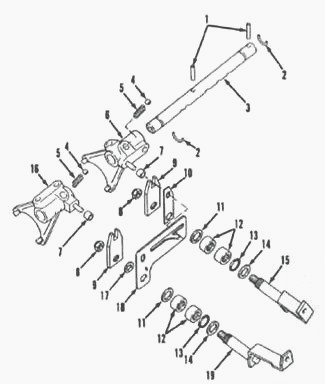

Remove snap rings (2). Drive out roll pins (1) and rotate shift rail (3)

to disengage detent balls (4) from slots in rail.

Move shift rail forward and cover shift fork (6) with a shop towel to prevent losing detent ball and spring. Rotate shift fork to remove bushing (7), then remove Lo-Reverse shift fork.

Remove Hi-Neutral shift fork (16) in same manner. Removal of shift

levers and shift arms is obvious after examination of the units and

reference to Figure.

On tractor models equipped with Forward-Reverse transmission, only one

shift lever and shift fork is used.

Fig.26. Shift levers, shift rail and shift forks used on Case IH

385, 585 range transmission

1.Roll pins, 2.Snap rings, 3.Shift rail, 4.Detent balls, 5.Detent

springs, 6.Lo-Reverse shift fork, 7.Bushings fork, 8.Nuts, 9.Shift arms,

10.Spacer plate, 11.Washers, 12. Needle bearings, 13.'0" rings,

14.Washers, 15.Lo-Reverse shift lever, 16.Hi-Neutral shift fork,

17,Washer, 18.Interlock plate, 19.Hi-Neutral shift lever

2 wheel drive Case IH 385, 585

tractors

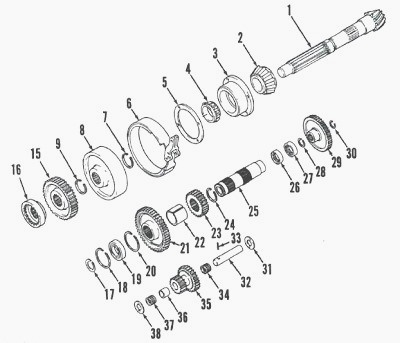

To remove the bevel pinion mainshaft (1), loosen park brake adjustment,

then unpin and remove park brake band (6). Remove snap ring (9) from

groove in bevel pinion shaft.

Unbolt bearing housing (3), move bevel pinion shaft rearward and remove

Hi sliding collar (16), Remove Lo-Reverse gear (15), snap ring (9) and

brake drum (8).

Remove bevel pinion mainshaft assembly with shims (5) from transmission

case. Measure and note thickness of shims if the same bevel pinion main

shaft is to be reinstalled. Using a dial indicator, measure end play of

bearing housing (3) on bearings (2 and 4).

If end play is more than 0.009 inch (0.229

mm), renew the bearings as follows:

Remove snap ring (7) and press bearings and housing from bevel pinion

main shaft. Install new bearings (2 and 4) and housing (3) and secure

with snap ring (7).

To remove the countershaft (25), remove snap ring (18) and remove snap

ring (24) from its groove in countershaft. Drive a wedge into split in

spacer (22). Move countershaft forward and remove snap ring (24), Lo

gear (23), split spacer (22) and constant mesh gear (21) as countershaft

is withdrawn.

Remove snap ring (17), then press ball bearing (19) from counter-shaft.

Pump drive gear (29) is located on pto driven shaft and rides in needle

bearing (27). If necessary, countershaft needle bearing (26) and pump

gear needle bearing (27) can now be removed. Note position of needle

bearings before removing.

To remove the reverse idler gear (35) and shaft (32), drive out roll pin

(33). Withdraw shaft (32) and remove reverse idler gear (35) with needle

bearings (34 and 37) and spacer (36), then remove thrust washers (31 and

38).

Clean and inspect all Case IH 385, 585 transmission parts and renew any

showing excessive wear or other damage. If bevel pinion mainshaft must

be renewed, bevel ring gear must also be renewed as they are available

only as a matched set.

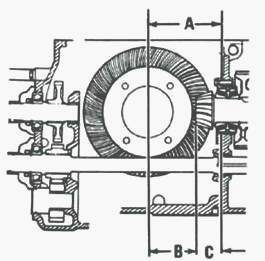

To set bevel pinion mainshaft position, install bearings (2 and 4),

housing (3) and snap ring (7). The mounting distance (A) from mainshaft

pinion bearing housing mounting face to the center line of the

differential is approximately 6.600 inches (167.64 mm).

This distance may vary for each tractor. To aid in accurate installation

of the pinion main-shaft, a single figure is stamped on the top face of

the upper pto shaft boss.

The single figure indicates (in inches) the variation from distance (A)

in steps of 0.001 inch (0.025 mm). When distance (A) is smaller, a minus

sign will be shown in front of single figure. Add or subtract the single

figure to the approximate distance 6.600 inches (167.64 mm).

The pinion cone mounting distance (B) is marked (in inches) on the rear

face of the pinion and shows the distance this face must be from center

line of differential. The distance will be approximately 4.410 inches

(112.01 mm).

Fig.27

Stand pinion shaft on a flat surface. Measure distance from pinion face

to the bearing housing mounting face. This is distance (C). Add distance

(C) to the marked figure on pinion face (distance B) and subtract from

the resulting (distance A).

The final figure is the correct thickness of shims (5) to be installed

for correct pinion mainshaft position. The balance of reassembly is the

reverse of disassembly procedures.

Fig.28. Case 385, 585 tractor Range transmission without front

drive axle. Note the light duty park brake (6 and 8)

1.Bevel pinion mainshaft , 2.Rear bearing,3.Bearing housing, 4.Front

bearing, 5.Shim, 6.Brake band, 7.Snap ring, 8.Brake drum, 9.Snap ring,

15.Lo-Reverse gear, 16.Hi sliding collar, 17.Snap ring, 18.Snap ring,

19.Ball bearing, 20.Snap ring, 21.Constant mesh gear, 22.Split spacer,

23.Lo gear, 24.Snap ring, 25.Countershaft, 26.Countershaft needle

bearing, 27.Pump drive gear needle bearing, 28.Snap ring, 29.Pump drive

gear, 30.Snap ring, 31.Thrust washer, 32.Shaft, 33.Roll pin, 34.Needle

bearing, 35.Reverse idler gear, 36.Spacer, 37.Needle bearing, 38.Thrust

washer

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| CASE IH TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| CASE IH FRONT END LOADERS SPECS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

CASE IH SPECS

CASE IH SPECS J.I. CASE SPECS

J.I. CASE SPECS PROBLEMS

PROBLEMS LOADERS

LOADERS FARMALL 110A

FARMALL 110A FARMALL 120A

FARMALL 120A FARMALL 30C

FARMALL 30C FARMALL 75C

FARMALL 75C MAGNUM 280

MAGNUM 280 580E Backhoe

580E Backhoe 580L Backhoe

580L Backhoe 580N Backhoe

580N Backhoe 580 Super L

580 Super L 580SM Backhoe

580SM Backhoe 580SLE Backhoe

580SLE Backhoe 580SN Backhoe

580SN Backhoe 580M Backhoe

580M Backhoe 580 Super E

580 Super E 580ST Backhoe

580ST Backhoe MAGNUM 310

MAGNUM 310 MAGNUM 340

MAGNUM 340 MAXXUM 110CVX

MAXXUM 110CVX MAXXUM 120CVX

MAXXUM 120CVX MAXXUM 125

MAXXUM 125 1394

1394 1455XL

1455XL 1494

1494 1594

1594 3230

3230 4210

4210 585XL

585XL 633

633 695XL

695XL 733

733 MX110

MX110 MX135

MX135 MX150

MX150 MXU110

MXU110 MXU135

MXU135 PUMA 175CVX

PUMA 175CVX PUMA 185CVX

PUMA 185CVX PUMA 200CVX

PUMA 200CVX PUMA 240CVX

PUMA 240CVX OPTUM 300

OPTUM 300 FARMALL 50B

FARMALL 50B FARMALL 95U

FARMALL 95U FARMALL 125A

FARMALL 125A PUMA 150

PUMA 150 PUMA 165

PUMA 165 MAGNUM 210

MAGNUM 210 MX 170

MX 170 MAXXUM 150

MAXXUM 150 OPTUM 270

OPTUM 270 MAGNUM 315

MAGNUM 315 FARMALL 70

FARMALL 70 FARMALL 75N

FARMALL 75N FARMALL 95C

FARMALL 95C FARMALL 105N

FARMALL 105N FARMALL 30B

FARMALL 30B L103 Loader

L103 Loader L104 Loader

L104 Loader L105 Loader

L105 Loader L106 Loader

L106 Loader L107 Loader

L107 Loader L108 Loader

L108 Loader L130 Loader

L130 Loader L160 Loader

L160 Loader L300 Loader

L300 Loader L340 Loader

L340 Loader L350 Loader

L350 Loader L360 Loader

L360 Loader L530 Loader

L530 Loader L540 Loader

L540 Loader L545 Loader

L545 Loader L550 Loader

L550 Loader L555 Loader

L555 Loader L560 Loader

L560 Loader L565 Loader

L565 Loader L570 Loader

L570 Loader L575 Loader

L575 Loader L720 Loader

L720 Loader L730 Loader

L730 Loader L735 Loader

L735 Loader L740 Loader

L740 Loader LRZ 95

LRZ 95 LRZ 100

LRZ 100 LRZ 120

LRZ 120 LRZ 130

LRZ 130 LRZ 150

LRZ 150 L745 Loader

L745 Loader L750 Loader

L750 Loader L755 Loader

L755 Loader L760 Loader

L760 Loader L765 Loader

L765 Loader L770 Loader

L770 Loader L775 Loader

L775 Loader L780 Loader

L780 Loader L785 Loader

L785 Loader L795 Loader

L795 Loader 90 Loader

90 Loader 890 Loader

890 Loader 2200 Loader

2200 Loader 2250 Loader

2250 Loader LX156 Loader

LX156 Loader