________________________________________________________________________________

John Deere AG150/AG250 transmission - Repairing the range clutch shaft

- All gear range clutch trains are dismantled in the same way.

- All the gear trains possess a clutch.

The Massey Ferguson 8270, 8210, 8260 tractor

gear range clutch trains are identified as follows:

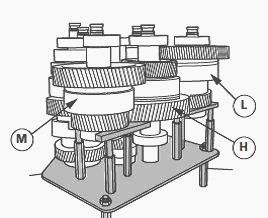

Fig.61

"L" clutch - 5th stage shaft

"H" clutch - 6th stage shaft

"M" clutch - 7th stage shaft

Take care that the shaft is properly supported to avoid toppling and

damage to the pinions.

- Install a suitable split bearing extractor (OEM 4175 or equivalent) on

the first bearing. The split bearing extractor must be placed in such a

manner that its flat surface is turned towards the pinion. Tighten the

extractor bolts until the bearing begins to extract from the 7th stage

shaft.

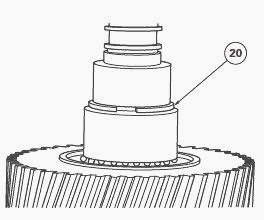

Fig.62

- Hook the pinion extractor beneath the split bearing extractor and

remove the bearing from the shaft by pulling. Remove the circlips (20)

from the shaft.

- Place the pinion extractor sleeve (ATP 3030) on the pinion and tighten

the bolts. To be able to extract the pinion from the shaft, the

extractor sleeve must be tightened around the external diameter of the

pinion. In certain cases, use of the main sleeve is specified and must

be fitted beneath the pinion. Hook the pinion extractor beneath the

extractor sleeve and remove the pinion and bearingfrom the shaft by

pulling upwards.

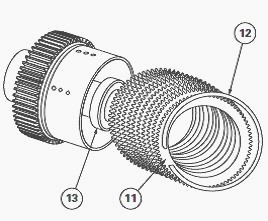

- Take off circlip (12) and closing plate (11), the thrust plates,

clutch discs and clutch housing.

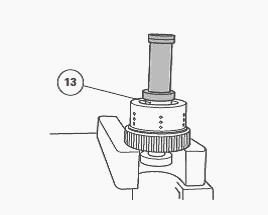

- Place a suitable pinion extractor on the internal pinion bearing (13)

and remove it from the shaft.

Fig.63

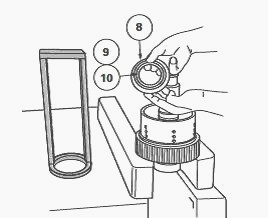

- Place the clutch train in a press. Place tool ATP 3002 on the

Belleville washers. Compress the washers, remove circlip and release the

pressure on the washers.

- Remove the MF 8270, 8210, 8260 tractor clutch train from the press and

take off the holding washer of circlip (9) and Belleville washers (8)

from the clutch.

Fig.64

- Remove the oil seal washer located between the Belleville washers (8)

and the clutch piston.

- Once all the Belleville washers are removed, feed compressed air into

the clutch pressurized oil channel, near shaft seal ring. This will

eject the piston from the clutch housing.

- Disassemble the opposite end of the shaft in the same manner. The best

method of supporting the shaft is to have a 76 mm diameter hole in the

workbench to receive the shaft.

- Compress the Belleville washers and remove the circlip using tool ATP

3002.

- Take off the washing retaining the circlip, the Belleville washers and

the oil seal washer.

- Remove the clutch piston.

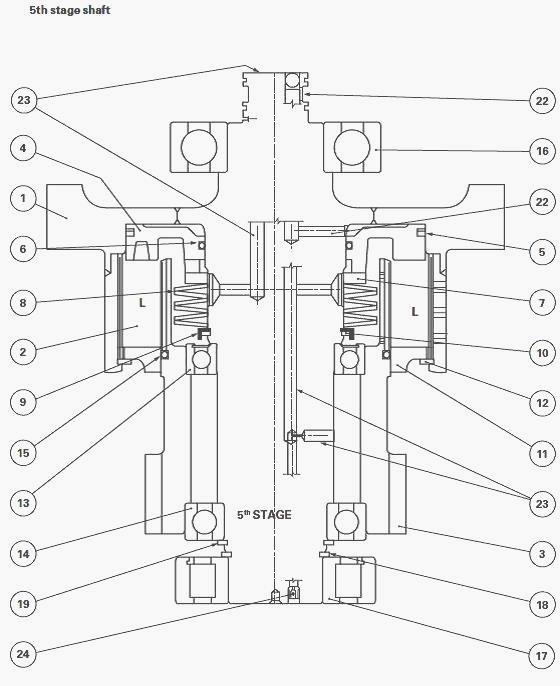

5th stage shaft

Massey Ferguson 8260, 8210, 8270 tractor AG

150 transmission (fig.65)

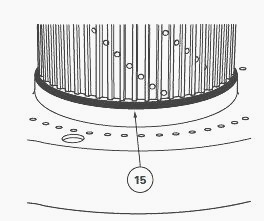

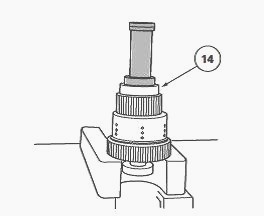

(1) 5th stage pinion shaft - 74 teeth (2) "L" clutch linings - 10 thrust

plates and discs (3) Pinion "L" clutch hub - 40 teeth. Use extractor

sleeves ATP 3030-1 and ATP 3030-10 to remove the pinion. (4) Clutch

piston (5) External piston seal - type "D" bush seal (6) Internal piston

seal - O’ring (7) Oil seal washer (8) Belleville washers (9) Circlip

retaining washer (10) Circlip (11) Closing plate (12) Clutch lining

circlip (13) Protected ball bearing of "L"clutch internal pinion hub

(14) Ball bearing of "L" clutch external pinion hub (15) Clutch

lubricating oil regulation O’ring (16) Forward shaft ball bearing (17)

Rear shaft roller bearing (18) Circlip (19) Circlip (22) "L" clutch

pressurized oil channel (23) Pressurized oil channel (24) Lubricating

port

Instructions

(13) The protected ball bearing must be installed with the protective

device facing the clutch linings.

(17) The roller bearing must be installed with the bearing circlip

facing the centre of the shaft

Fig.65. 5th stage shaft

MF 8260, 8210, 8270 tractor AG 250

transmission

(1) 5th stage pinion shaft - 80 teeth (2) "L" clutch linings - 10 thrust

plates and discs (3) Pinion "L" clutch hub - 44 teeth. Use extractor

sleeves ATP 3030-1 and ATP 3030-12 to remove the pinion. (4) Clutch

piston (5) External piston seal - type "D" bush seal (6) Internal piston

seal - O’ring (7) Oil seal washer (8) Belleville washers (9) Circlip

retaining washer (10) Circlip (11) Closing plate (12) Clutch lining

circlip (13) Protected ball bearing of "L" clutch internal pinion hub

(14) Ball bearing of "L" clutch external pinion hub (15) Clutch

lubricating oil regulation O’ring (16) Forward shaft ball bearing -

hardened bearing (17) Rear shaft roller bearing (18) Circlip (19)

Circlip (22) "L" clutch pressurized oil channel (23) Pressurized oil

channel (24) Lubricating port

Instructions

(13) The protected ball bearing must be installed with the protective

device facing the clutch linings.

(16) The SH2 bearing must be installed here. The SH2 bearing is a

hardened bearing providing twice the normal life span.

(17) The roller bearing must be installed with the bearing circlip

facing the centre of the shaft

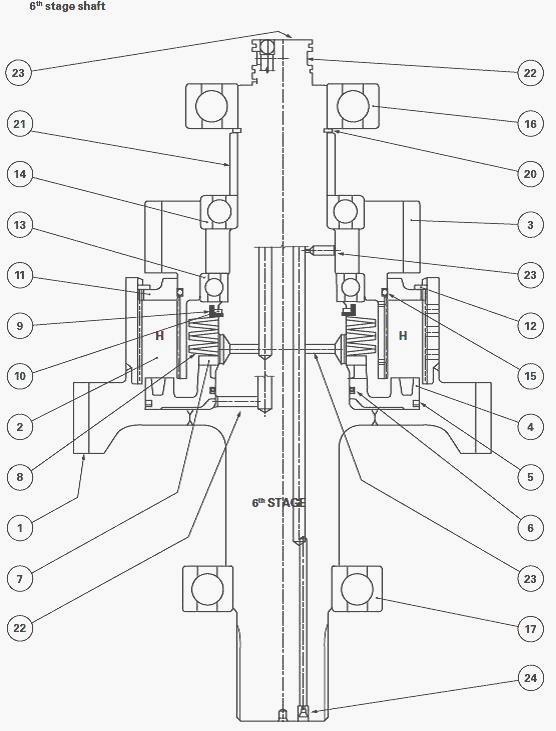

6th stage shaft

John Deere AG 150 transmission (Fig.66)

(1) 6th stage pinion shaft - 72 teeth (2) "H" clutch linings - 10 thrust

plates and discs (3) Pinion - "H" clutch hub - 48 teeth. Use extractor

sleeves ATP 3030-1 and ATP 3030-155 to remove the pinion. (4) Clutch

piston (5) External piston seal - type "D" bush seal (6) Internal piston

seal - O’ring (7) Oil seal washer (8) Belleville washers (9) Circlip

retaining washer (10) Circlip (11) Closing plate (12) Clutch lining

circlip (13) Protected ball bearing of "H" clutch internal pinion hub

(14) Ball bearing of "H" clutch external pinion hub (15) Clutch

lubricating oil regulation O’ring (16) Forward shaft ball bearing (17)

Rear shaft roller bearing (20) Circlip (21) Distance piece sleeve (22)

"H" clutch pressurized oil channel (23) Pressurized oil channel (24)

Lubricating port

Instructions

(13) The protected ball bearing must be installed with the protective

device facing the clutch linings.

Fig.66. 6th stage shaft

John Deere AG 250 transmission

(1) 5th stage pinion shaft - 81 teeth (2) "H" clutch linings - 10 thrust

plates and discs (3) Pinion "H" clutch hub - 53 teeth. Use extractor

sleeves ATP 3030-1 and ATP 3030-16 to remove the pinion. (4) Clutch

piston (5) External piston seal - type "D" bush seal (6) Internal piston

seal - O’ring (7) Oil seal washer (8) Belleville washers (9) Circlip

retaining washer (10) Circlip (11) Closing plate (12) Clutch lining

circlip (13) Protected ball bearing of "H" clutch internal pinion hub

(14) Ball bearing of "H" clutch external pinion hub (15) Clutch

lubricating oil regulation O’ring (16) Forward shaft ball bearing -

hardened bearing (17) Rear shaft roller bearing - hardened bearing (20)

Circlip (21) Distance piece sleeve (22) "H" clutch pressurized oil

channel (23) Pressurized oil channel (24) Lubricating port

Instructions

(13) The protected ball bearing must be installed with the protective

device facing the clutch linings.

(16) The SH2 bearing must be installed here. The SH2 bearing is a

hardened bearing providing twice the normal life span.

(17) The SH2 bearing must be installed here. The SH2 bearing is a

hardened bearing providing twice the normal life span.

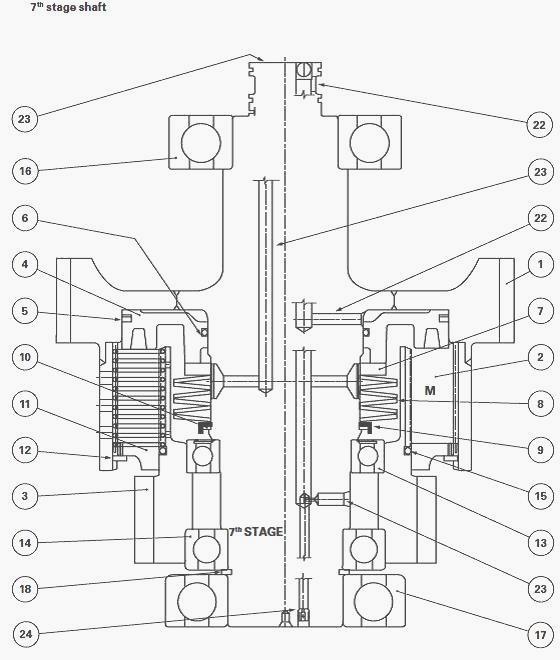

7th stage shaft

Massey Ferguson 8210, 8270, 8260 tractor AG

150 transmission (Fig.67)

(1) 7th stage pinion shaft - 65 teeth (2) "M" clutch linings - 10 thrust

plates and discs (3) Pinion "M" clutch hub - 40 teeth. Use extractor

sleeves ATP 3030-1 and ATP 3030-10 to remove the pinion. (4) Clutch

piston (5) External piston seal - type "D" bush seal (6) Internal piston

seal - O’ring (7) Oil seal washer (8) Belleville washers (9) Circlip

retaining washer (10) Circlip (11) Closing plate (12) Clutch lining

circlip (13) Protected ball bearing of "M" clutch internal pinion hub

(14) Ball bearing of "M" clutch external pinion hub (15) Clutch

lubricating oil regulation O’ring (16) Forward shaft ball bearing (17)

Rear shaft roller bearing (18) Circlip (22) "M" clutch pressurized oil

channel (23) Pressurized oil channel (24) Lubricating port

Instructions

(13) The protected ball bearing must be installed with the protective

device facing the clutch linings.

Fig.67. 7th stage shaft

MF 8270, 8210, 8260 tractor AG 250

transmission

(1) 7th stage pinion shaft - 75 teeth (2) "M" clutch linings - 10 thrust

plates and discs (3) Pinion "M" clutch hub - 47 teeth. Use extractor

sleeves ATP 3030-1 and ATP 3030-13 to remove the pinion. (4) Clutch

piston (5) External piston seal - type "D" bush seal (6) Internal piston

seal - O’ring (7) Oil seal washer (8) Belleville washers (9) Circlip

retaining washer (10) Circlip (11) Closing plate (12) Clutch lining

circlip (13) Protected ball bearing of "M" clutch internal pinion hub

(14) Ball bearing of "M" clutch external pinion hub (15) Clutch

lubricating oil regulation O’ring (16) Forward shaft ball bearing -

hardened bearing (17) Rear shaft roller bearing - hardened bearing (18)

Circlip (22) "M" clutch pressurized oil channel (23) Pressurized oil

channel (24) Lubricating port

Instructions

(13) The protected ball bearing must be installed with the protective

device facing the clutch linings.

(16) The SH2 bearing must be installed here. The SH2 bearing is a

hardened bearing providing twice the normal lifetime

(17) The SH2 bearing must be installed here. The SH2 bearing is a

hardened bearing providing twice the normal lifetime

Assembling Massey Ferguson 8270, 8210,

8260 tractor range clutches

- Place the clutch train vertically on the workbench. Install the

internal and external seals on the piston (4). Smear the piston seals

and clutch-housing bore with transmission oil. Fit piston (4) with the

reinforcements and depressions facing outside.

- Install an oil seal washer (7). All the clutch oil seal washers of the

range are identical.

- Install a Belleville washer (8). The first washer closest to the

piston must touch the internal rim of the washer. The second Belleville

washer must touch the external rim of the first washer. Alternate

Belleville washers until they are all installed.

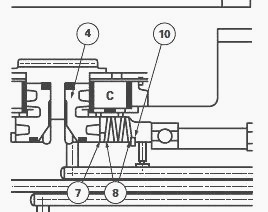

Fig.68

(4) Piston, (7) Oil seal washer, (8) Belleville washers, (10) Circlip

- Place the clutch train in a press. Using tool ATP 3002, compress the

Belleville washers and fit retaining washer and a circlip (10).

- Lubricate the thrust plates and discs with transmission oil as they

are installed. Begin with the thrust plate closest to the piston and

alternate until the 10 thrust plates and 10 friction disks are

installed. Place the splined clutch closing plate on the outside and fit

circlip.

Measuring piston travel

- Using slide callipers fitted with a depth gauge, measure distance A

from the piston to the edge of the clutch housing.

- Inject 4.8 bar compressed air in the oil channel to compress the

Belleville washers. Measure distance B from the piston to the edge of

the clutch housing.

- The difference between these two measurements, A - B equals the piston

travel.

Piston travel

- The piston travel can be adjusted by selecting or exchanging thrust

plates since their thickness varies.

- With new clutch discs and thrust plates - Piston travel: 1.3 to 3.8 mm

- With used clutch discs and thrust plates - Piston travel: 1.8 to 5.5

mm

Reassembling Massey Ferguson 8270,

8210, 8260 tractor clutch range bearings

Certain bearings used in the clutches and on the shafts are directional

and must be installed in the correct direction.

- Push bearing (13) the closest to the clutch linings, on to the shaft

using a compression tool (ATP 3020). Install the bearing with the

protective device facing the clutch lining.

Fig.69

- Install the oil regulation o’ring (15) on clutch hub and lubricate the

o’ring.

Fig.70

- Install the pinion with the clutch hub (3) in the discs and thrust

plates, over the bearing. The pinion being placed above the bearing.

Turn the pinion and shake lightly so that all the splines of the discs

and thrust plates are correctly engaged and so that the bearing thrusts

against the bottom of the pinion bore.

Fig.71

When fitting the hub, ensure that the oil regulation O’ring (15) is not

pinched when it passes the closing plate. The O’ring must be positioned

so that it is loose on the clutch hub.

- Install external pinion hub bearing (14) on the shaft using a

compression tool (ATP 3020) and push it into the pinion hub. Install a

circlip on the shaft of the fifth or seventh stage, or a sleeve and a

circlip on the sixth stage shaft.

Fig.72

- Place an extraction sleeve (ATP 3030) on the pinion, pull the pinion

and the bearing upwards against the circlip to avoid any lateral load on

the bearings. The hub of the pinion must move longitudinally.

- Place the bearings on the shaft and push them home using a compression

tool (ATP 3020). Bearing of the fifth stage clutch train is a roller

bearing and must be installed so that the bearing circlip faces the

clutch.

- Repeat the procedure at each end of the shaft and for all the speed

clutch shafts.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

JD SPECS

JD SPECS JD LOADERS

JD LOADERS JD MAINTENANCE

JD MAINTENANCE JD INSTRUCTIONS

JD INSTRUCTIONS JD PROBLEMS

JD PROBLEMS JD 2025R

JD 2025R JD 3039R

JD 3039R JD 4044R

JD 4044R JD 4105

JD 4105 JD 4720

JD 4720 420 Loader

420 Loader 419 Loader

419 Loader 510 Loader

510 Loader 512 Loader

512 Loader 520 Loader

520 Loader 520M Loader

520M Loader 540M NSL

540M NSL 540 Loader

540 Loader 440R Loader

440R Loader H180 Loader

H180 Loader JD 5045E

JD 5045E JD 5085E

JD 5085E JD 5100M

JD 5100M JD 6105R

JD 6105R JD 6120M

JD 6120M JD 6155M

JD 6155M JD 6195R

JD 6195R JD 6210R

JD 6210R JD 7210R

JD 7210R JD 7250R

JD 7250R JD 7310R

JD 7310R JD 8245R

JD 8245R JD 8295R

JD 8295R JD 8370R

JD 8370R JD 9370R

JD 9370R 120R Loader

120R Loader D120 Loader

D120 Loader H120 Loader

H120 Loader 45 Loader

45 Loader 200CX Loader

200CX Loader D160 Loader

D160 Loader D170 Loader

D170 Loader H160 Loader

H160 Loader H165 Loader

H165 Loader H240 Loader

H240 Loader 210 Loader

210 Loader 220R Loader

220R Loader 300E Loader

300E Loader 300X Loader

300X Loader 300CX Loader

300CX Loader JD 9420R

JD 9420R JD 9510R

JD 9510R JD GX335

JD GX335 JD GX85

JD GX85 JD LA105

JD LA105 JD 5065M

JD 5065M JD 5055D

JD 5055D JD 5115R

JD 5115R JD 5105M

JD 5105M JD 6110R

JD 6110R JD 6130D

JD 6130D JD 6225

JD 6225 JD 7530

JD 7530 JD 4044M

JD 4044M JD 7185J

JD 7185J 300 Loader

300 Loader 300R Loader

300R Loader 320R Loader

320R Loader 400E Loader

400E Loader 410 Loader

410 Loader 430 Loader

430 Loader 460 Loader

460 Loader 521 Loader

521 Loader 531 Loader

531 Loader 541 Loader

541 Loader 551 Loader

551 Loader 631 Loader

631 Loader 651 Loader

651 Loader 661 Loader

661 Loader 603R Loader

603R Loader JD D130

JD D130 JD D160

JD D160 JD 325

JD 325 JD 335

JD 335 JD 345

JD 345 JD 2520

JD 2520 JD 3005

JD 3005 JD 3720

JD 3720 JD 1025R

JD 1025R JD 3033R

JD 3033R JD 5090EL

JD 5090EL JD 5100MH

JD 5100MH JD 5075GV

JD 5075GV JD 6090RC

JD 6090RC JD 6110B

JD 6110B 623R Loader

623R Loader 643R Loader

643R Loader 731 Loader

731 Loader 746 Loader

746 Loader 751 Loader

751 Loader 533 Loader

533 Loader 583 Loader

583 Loader 633 Loader

633 Loader 653 Loader

653 Loader 683 Loader

683 Loader H260 Loader

H260 Loader 663R Loader

663R Loader 663 Loader

663 Loader 683R Loader

683R Loader 753 Loader

753 Loader JD 6125J

JD 6125J JD 6150RH

JD 6150RH JD 6210J

JD 6210J JD 7195J

JD 7195J JD 8310

JD 8310 JD 6325

JD 6325 JD 5525

JD 5525 JD 5083EN

JD 5083EN JD 5100GN

JD 5100GN JD 5125R

JD 5125R 210C Backhoe

210C Backhoe 300D Backhoe

300D Backhoe 310G Backhoe

310G Backhoe 410G Backhoe

410G Backhoe 710G Backhoe

710G Backhoe 80 Loader

80 Loader 100 Loader

100 Loader 146 Loader

146 Loader 148 Loader

148 Loader 158 Loader

158 Loader 168 Loader

168 Loader 175 Loader

175 Loader 522 Loader

522 Loader 542 Loader

542 Loader 540R Loader

540R Loader 562 Loader

562 Loader 563 Loader

563 Loader 673 Loader

673 Loader 741 Loader

741 Loader L108 Automatic

L108 Automatic L120 Automatic

L120 Automatic LA110 Automatic

LA110 Automatic LA120 Automatic

LA120 Automatic LA150 Automatic

LA150 Automatic LT155

LT155 LT160 Automatic

LT160 Automatic LT180 Automatic

LT180 Automatic LTR180

LTR180 X165

X165 E100

E100 E120

E120 E150

E150 LTR166

LTR166 LA135

LA135 LA165

LA165 LX277

LX277 LX288

LX288 LX255

LX255 S240

S240 GT235

GT235 G110 Automatic

G110 Automatic JD 3203

JD 3203 JD 5520

JD 5520 JD 316

JD 316 JD 420

JD 420 JD 425

JD 425 JD 445

JD 445 JD_5050D

JD_5050D X300

X300 X304

X304 X310

X310 X110 Automatic

X110 Automatic H310 Loader

H310 Loader H340 Loader

H340 Loader H360 Loader

H360 Loader H380 Loader

H380 Loader H480 Loader

H480 Loader 240 Loader

240 Loader 245 Loader

245 Loader 260 Loader

260 Loader 265 Loader

265 Loader 600R Loader

600R Loader 620R Loader

620R Loader 640R Loader

640R Loader 660R Loader

660R Loader 680R Loader

680R Loader JD_5039D

JD_5039D X146R

X146R X360

X360 X155R

X155R X140 Automatic

X140 Automatic X350

X350 X380

X380 X500

X500 X590

X590 X700

X700 3036E

3036E 2038R

2038R 3038R

3038R 4049M

4049M JD 4100

JD 4100 X738

X738 X740

X740 X748

X748 X749

X749 X950R

X950R JD 4510

JD 4510 5045D

5045D 5050E

5050E 5060E

5060E 5078E

5078E