________________________________________________________________________________

Massey Ferguson 3050, 3060, 3080, 3125 PTO - Intermediate shaft, Driving pinion, Power-take-off brake

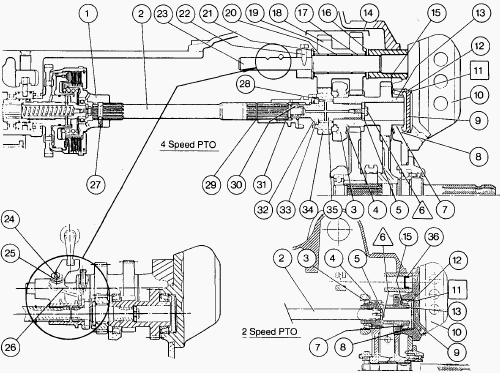

The drive from the engine is transmitted to the power take-off clutch

mounted at the front of the center housing. The intermediate shaft (2)

is connected by splines at one end to the clutch and at the other end

either to the double pinion (13) in the 2-speed PTO version or to the

coupler (31) in the 4-speed economy PTO version. The compound pinion

(13) turns on two taper roller bearings (3) (4) and (7) (8), mounted in

the bore of the center housing and the top link support (10)

respectively. A piston housed in the 3rd point support and controlled by

the 17 bar hydraulic circuit enables the compound pinion (13) to be

braked when the control lever is moved to the PTO braking position.

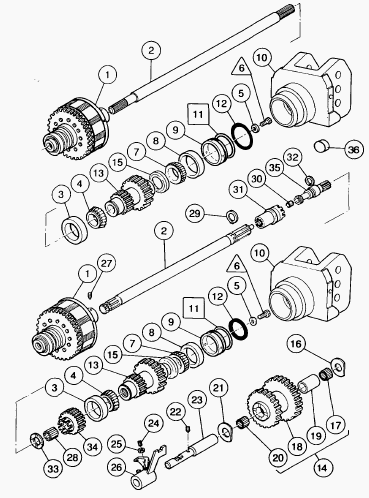

Parts List - (1) Clutch, (2) Intermediate shaft, (3)

Bearing cup, (4) Bearing cone, (5) Washer, (6) Bolt, (7) Bearing cone,

(8) Bearing cup, (9) Brake piston, (10) Top link support, (11) Shims,

(12) O-ring, (13) Driving pinion, (14) Compound pinion assembly, (15)

Deflector, (16) Washer, (17) Needle roller bearing, (18) Compound

pinion, (19) Spacer, (20) Needle roller bearing, (21) Washer, (22) Set

screw, (23) Shaft, (24) Locking screw, (25) Nut, (26) Fork, (27) Screw,

(28) Needle roller bearing, (29) Circlip, (30) Ring, (31) Dog tooth

coupler, (32) Circlip, (33) Washer, (34) Dog tooth pinion, (35) Shaft,

(36) Cup plug

MF 3050, 3060, 3080, 3125 PTO Operation

2-speed PTO

When the PTO solenoid valve feeds the clutch, the intermediate shaft (2)

is driven. This in turn drives the compound driving pinion (13) which

engages constantly with the 540 rpm and 1000 rpm pinions of the lower

line.

4-speed PTO

This feature enables speeds of 540 rpm or 1000 rpm to be obtained with

an engine speed of 1550 rpm. Standard position (engine speed 2000 rpm) -

When the coupler (31) is moved forwards, the intermediate shaft (2)

turns with the shaft (35) which drives the compound driving pinion (13).

This configuration is identical to the 2-speed PTO version. Economy

position (engine speed 1550 rpm) - When the coupler (31) is moved

backwards, the drive is transmitted to the coupler (34) (fitted loose on

the Shaft (35)) and to the compound pinion (18) which drives the driving

pinion (13). The ratio of the Compound pinion (18) is 1.292.

Power-take-off brake

The movement of the control lever in the cab acts on an electrical

contactor which enables the solenoid valve of the PTO brake mounted on

the right cover to open. Oil is supplied to the chamber situated behind

the piston (9). The piston moves and presses the bearing cup (8) against

the bearing cone (7), progressively immobilizing the driving pinion (13)

which constantly engages with the 540 and 1000 rpm pinions.

Massey Ferguson 3050, 3060, 3080, 3125 -

2-speed PTO

Disassembly

Disconnect: auxiliary spool valve supply hose; supply hose of the lift

valve; return hose. Remove the bolts of the auxiliary spool valve

support. Detach the auxiliary spool valve support. Tilt the support and

auxiliary spool valve assembly without detaching the control cables.

Disconnect the supply tube of the PTO brake. Disconnect the lubrication

tube. Remove the bolts and the top link support. Withdraw the pinion and

shaft assembly held by the washer and screw. Remove the bearing cone.

The shaft (2) is mounted in the clutch (1) without locking screw.

Reassembly

Check and clean the parts. Replace those which are defective. Refit the

bearing cone. Fit the pinion (13) and shaft (2) assembly held by the

washer (5) and screw. Clean the joint face of the top link support.

Smear the joint face of the housing with a sealing compound (Loctite 510

or equivalent). To ensure the lubrication of the bearing cone, a cup

plug (36) is fitted without Loctite, recessed into the face of the

housing.

Refit the top link support. Fit and tighten the bolts to a torque of 130-170 Nm. Ensure that the cup is present. Reconnect the supply tube of the PTO brake and the lubrication tube. Clean the joint face of the spool valve support. Smear the joint face of the support cover with a sealing compound (Loctite 510 or equivalent). Refit the support, tilting it. with the control cables.

Smear the threads of the

two lower bolts with Loctite 510. Fit and tighten the bolts to a torque

of 50-70 Nm. Reconnect: spool valve supply hose; supply hose of the lift

valve; return hose. Check the operation of the PTO and its brake. Check

for leaks at the joint faces (spool valve support, top link support); at

the hydraulic connectors.

Massey Ferguson 3050, 3060, 3080, 3125 - 4-speed economy PTO

Disassembly

Remove the left side cover. If removing the screw (27) and the

intermediate shaft (2). Disconnect: spool valve supply hose; supply hose

of the lift valve; return hose. Remove the support. Tilt the support and

spool valve assembly without detaching the cables. Disconnect the

lubrication tube. Remove the bolts of the top link support and detach

it. Remove the nut and the locking screw of the fork. Remove the screw

(22).

Withdraw the shaft (23) from the compound pinion assembly (14) in order to disengage the fork (26). To disengage the fork atone, gently putt the shaft (23) towards the rear. Remove the friction washers (16) and (21). Take care not to drop the washers in the housing. Withdraw the compound pinion assembly (14) (through the aperture of the spool valve support for version without shimming only).

Remove the needle roller bearings (17) and (20) and the spacer (19) of the pinion (18). Remove the circlip (32). Use short-handled pliers to facilitate access to the circlip. Withdraw the pinion (13) and shaft (35) assembly held by the washer (5) and bolt. Remove the flat washer (33). Take care not to drop the circlip and the washer in the housing. Hold the pinion (34) and the needle roller bearing (28).

The bearing cone (4) remains in the cup (3)

during removal of the pinion (13). Remove the pinion (34) and the needle

roller bearing (28). Remove the bearing cone (4). Remove the hexagon

socket setscrew (27) (if necessary). Withdraw the shaft (2) and the

coupler (31) (if necessary). The circlip (29) remains on the shaft (2).

Reassembly

Clean and check the parts. Replace those which are defective. Refit the

shaft (2) and the coupler (31) (if removed). Smear the screw (27) with

Loctite 221 and tighten (if removed). Refit the bearing cone. Advance

the pinion (13) prepared with the shaft (35). Fit the coupler (34), the

needle roller bearing (28), the washer (33) and the circlip. Push on to

the pinion (13). Position the washer (33). Fit the circlip (32).

In the pinion (18), place the spacer (19) and the needle roller bearings (17) and (20). Position the compound pinion assembly (14). Fit the washer (16) smeared with miscible grease (Amber Technical or equivalent). Lightly engage the shaft (23) to hold the washer (16) in place. Fit the washer (21) smeared with miscible grease. Centre the compound pinion assembly (14).

Mount the shaft (23) finally in the pinion assembly (14)

and in the fork (26), ensuring that the hole of the screw (22) is

properly positioned. Smear the screw (22) with Loctite 542. Fit and

tighten to a torque of 28-43 Nm. Clean the joint face of the top link

support. Smear the joint face of the housing with a sealing compound

(Loctite 510 or equivalent). Ensure that the cup is present. Fit and

tighten the bolts to a torque of 130-170 Nm. Reconnect the tubes. Refit

the screw (24) and the nut (25) on the fork (26).

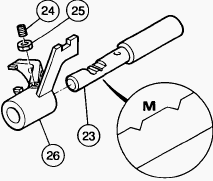

Adjustment of locking of fork (26): Position the fork (26) and the

locking screw (24) on the flat part M of the shaft (23) (between the two

locking notches). Tighten the screw as far as it will go so as to

compress the ball. Loosen the screw by 1/4 of a turn. Smear the nut (25)

with Loctite 241. Tighten to a torque of 15-20 Nm. Check that the fork

is locked correctly. Adjust the control. Clean the joint face of the

spool valve support.

Smear the joint face of the support with a sealing compound (Loctite 510 or equivalent). Refit the support, tilting it, with the control cables. Smear the threads of the two lower bolts with Loctite 510. Tighten the four screws to a torque of 50-70 Nm. Reconnect the hoses. If the screw and intermediate shaft (2) have been removed, refit the left side cover. Check the operation of the PTO and its brake. Check for leaks at the joint faces (spool valve support, top link support, left side cover), at the hydraulic connectors.

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF FRONT END LOADERS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS MAINTENANCE |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS TROUBLESHOOTING | ||||

| 1652 | 1749 | 2620 | 2725 | 2805 |

| 3050 | 3120 | 3640 | 3709 | 4245 |

| 4455 | 5320 | 5455 | 5613 | 6150 |

| 6280 | 6480 | 6615 | 7618 | 7720 |

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS 130

130 133

133 145

145 155

155 158

158 165

165 175

175 185

185 188

188 230

230 254

254 254S

254S 284S

284S 294

294 353

353 290

290 362

362 375

375 390

390 398

398 399

399 590

590 690

690 1010

1010 1030

1030 1020

1020 1150

1150 2620

2620 2640

2640 2645

2645 1540

1540 2660

2660 3065

3065 3095

3095 3650

3650 3680

3680 4255

4255 4355

4355 4370

4370 3630

3630 3635

3635 4245

4245 4445

4445 4609

4609 4710

4710 5435

5435 5475

5475 5610

5610 5711

5711 6150

6150 6170

6170 6180

6180 6270

6270 6290

6290 6445

6445 6499

6499 6614

6614 6713

6713 7465

7465 7495

7495 7614

7614 7622

7622 7715

7715 7726

7726 8210

8210 8270

8270 8650

8650 8727

8727 GC1705

GC1705 1464 Loader

1464 Loader 1466 Loader

1466 Loader 1040 Loader

1040 Loader 1070 Loader

1070 Loader 905 Loader

905 Loader 906 Loader

906 Loader 915 Loader

915 Loader 916 Loader

916 Loader 921 Loader

921 Loader 926 Loader

926 Loader 931 Loader

931 Loader 933 Loader

933 Loader 936 Loader

936 Loader 938 Loader

938 Loader 939 Loader

939 Loader 940 Loader

940 Loader 941 Loader

941 Loader 945 Loader

945 Loader 946 Loader

946 Loader 948 Loader

948 Loader 949 Loader

949 Loader 950 Loader

950 Loader 951 Loader

951 Loader 955 Loader

955 Loader 956 Loader

956 Loader 958 Loader

958 Loader 960 Loader

960 Loader 961 Loader

961 Loader 965 Loader

965 Loader 966 Loader

966 Loader 968 Loader

968 Loader 975 Loader

975 Loader 976 Loader

976 Loader 978 Loader

978 Loader 985 Loader

985 Loader FL.3114 X

FL.3114 X FL.3419 X

FL.3419 X FL.3522

FL.3522 FL.3615

FL.3615 FL.3619

FL.3619 FL.3817

FL.3817 FL.3819

FL.3819 FL.3823

FL.3823 FL.4018

FL.4018 FL.4121

FL.4121 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader FL.4125

FL.4125 FL.4227

FL.4227 FL.4124

FL.4124 FL.4220

FL.4220 FL.4323

FL.4323 FL.4327

FL.4327 FL.4621

FL.4621 FL.4624

FL.4624 FL.4628

FL.4628 FL.5033

FL.5033 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader 1010

1010 1020

1020 1030

1030 1035

1035 1040

1040 1045

1045 1080

1080 1085

1085 1120

1120 1125

1125 1140

1140 1160

1160 1165

1165 1180

1180 1190

1190 1205

1205 1210

1210 1215

1215 1220

1220 1225

1225 1230

1230 1233

1233 1235

1235 1240

1240 1260

1260