________________________________________________________________________________

Massey Ferguson 3050, 3060, 3065, 3080 - Rear Axle Trumpet Housings

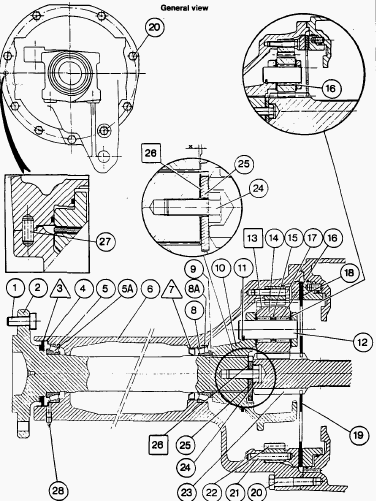

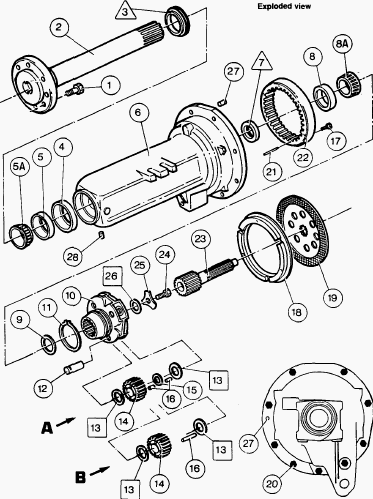

The trumpet housings support the RH and LH axle shafts and house the

final reduction units which transmit the drive from the differential

assembly. There are two versions of the rear axle, normal and heavy

duty, depending on the size of tractor: normal for the MF 3050, 3060 and

3065 tractors and heavy duty for MF 3070, 3080 and 3095 tractors. The

two trumpet housings are identical and are fitted on either side of the

center housing.

Massey Ferguson 3050, 3060, 3065, 3080 -

Trumpet Housings Construction

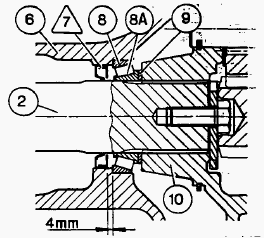

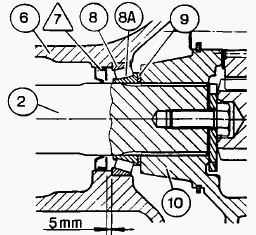

The half shaft (2) is supported by two taper roller bearings (5) and (8)

fitted opposite each other. The unit is sealed on the outside by a

triple lip seal and on the inside by a single lip seal. The final

reduction planetary carrier assembly (10) fitted with three pinions (14)

is splined onto the half shaft (2).

The heavy duty planetary carrier assemblies comprise two rows of needle rollers (16) separated by a spacer (15). The normal duty planetary carrier assemblies have only one row of needle rollers (16). The recesses in carrier assemblies (10) are rough finished and as such planetary gears (14) end float is adjusted by fitting suitable thickness thrust washer (13).

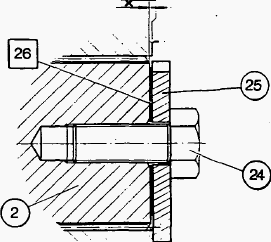

Shims located at the end of the axle shaft allow the taper roller

bearing preload to be adjusted. The half shaft (2) and the planetary

carrier assembly (10) are held by the washer (25) and the bolt (24). The

ring gear (22) is a force fit in the trumpet housing and attached by

three bolts (17). It comprises three locating dowels (21) which center

the brake plate (18). Drive from the differential is transmitted to the

final reduction planetary gears through a planetary shaft (23) on to

which the brake disc (19) is splined.

Parts List - (1) Wheel stud, (2) Axle shaft, (3) Triple

lip seals, (4) Seal housing, (5) Bearing cup, (5A) Bearing cone, (6)

Trumpet housing, (7) Seal, (8) Bearing cup, (8A) Bearing cone, (9) Sour

washer, (10) Planetary carrier assembly, (11) Circlip, (12) Planetary

gear pin, (13) Thrust washer(s), (14) Planetary gear, (15) Spacer (heavy

duty planetary carrier assembly), (16) Needle rollers, (17) Bolt, (18)

Brake plate, (19) Brake disc, (20) Bolt, (21) Locating dowel, (22) Ring

gear, (23) Planetary shaft, (24) Bolt, (25) Washer, (26) Shims, (27)

Locating dowel, (28) Plug

Massey Ferguson 3050, 3060, 3065, 3080 -

Trumpet housing assembly

Removal

Immobilize the tractor. Apply the handbrake. Fit chocks between the

frame and the front axle. Drain the rear axle only. Using a trolley

jack, raise the side of the tractor involved. Support the tractor with

an axle stand. Remove the wheel. Remove the stabilizer bracket.

Disconnect the draft control sensor harness.

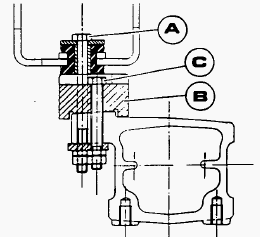

On MF 3050, 3060, 3080, 3065, 3070, 3095, 3120, 3125 tractors fitted

with an automatic hitch, the sensor is removed outwards. Remove the cab

attaching bolts (A) (Low profile cab) - (Hiline cab). Raise the cab

sufficiently to prevent any louling when the trumpet housing is removed

(chock the cab).

Check the clearance between the hood and the windscreen (if insufficient remove the sheet metal). Remove the spacer (B). Only for trumpet housing replacement on hiline cab tractors, remove bolts (A) and (C) and the spacer В. Position a suitable support on a trolley jack under the trumpet housing. For the LH trumpet housing disconnect the lift hydraulics valve supply hose (plug the ends).

Unscrew the attaching bolts (20). Pull the trumpet housing away from the

rear axle housing. Remove: brake disc (19); planetary shaft (23);

locating dowel (27). To prevent the brake piston from coming out of the

housing, it is recommended that two wide washers and two bolts be fitted

diametrically opposite each other to hold it in place. Remove the brake

plate (18).

Massey Ferguson 3050, 3060, 3065, 3080 -

Refitment

Clean the mating faces of the center housing and the trumpet housing

with a non-greasy solvent. Apply a bead of oil resistant (Silicomet

type) silicone to the inner edge of the center housing. Do not block up

the oil drain hole in the housing. Check that the disk (19) slides

freely on the planetary shaft (23). Refit the locating dowel (27), the

planetary shaft (23) and the brake disc (19).

Screw two dowel pins into diametrically opposite positions on the center housing. Refit the brake plate (18) in the trumpet housing. To retain the plate, apply three spots of "Amber Technical” grease or an equivalent product to the surface of the ring gear (22). Fit the trumpet housing to the center housing. Turn the shaft (2) to engage the planetary shaft (23) in the planetary gears.

Clean the bolts (20) and coat them with Plastex. Hylomar or an equivalent gasket sealant. Fit and tighten the bolts (20) to a torque of 170-210 Nm. Refit the cab attaching bolts with the nuts and locknuts to a torque of: Nut - 27-35 Nm, Locknut: 13-20 Nm (with Loctite 270). Refit the draft control sensor. Lightly coat the draft control sensor with Loctite Anti-seize or equivalent grease.

Reconnect the draft control sensor harness and refit the stabilizer

bracket. Replenish transmission oil. Refit the wheel. Tighten to a

torque of 400-450 Nm. Remove the axle stand. Test the hydraulic lift and

brake circuits. Check for leaks: between the trumpet housing and the

rear axle housing from the lift system valve supply hose (LH trumpet

housing).

Massey Ferguson 3050, 3060, 3065, 3080 -

Planetary carrier assembly

Disassembly

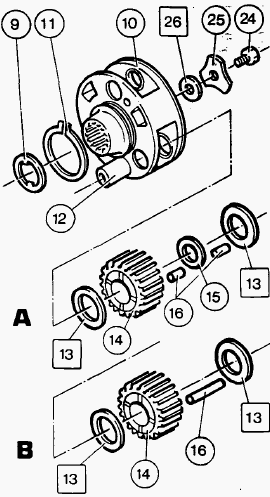

Remove the trumpet housing. Remove the bolt (24). Remove the retaining

washer (25) and the shim(s). Remove the planetary carrier assembly (10).

Open out the circlip (11). Using a copper tipped mallet, tap lightly on

the three pins (12). Remove the three pins (12) and the circlip (11).

Remove the three planetary gears (14), the needle rollers (16), the

spacers (15) (heavy duty planetary gear A) and the thrust washers.

Reassembly

Clean the planetary carrier (10), the pins (12) and the planetary gears

(14). Check the condition of the parts. Coat the needle rollers (16)

with "Amber Technical" or an equivalent grease. Into each planetary gear

(14) insert: Heavy duty planetary carrier (A) - two rows of needle

rollers separated by a spacer (15). Normal duty planetary carrier (B) -

one row of needle rollers. Each heavy duty planetary gear (A) has 42

needle rollers.

Each normal duty planetary gear (B) has 21 needle rollers. Shim the planetary gears. Position the planetary gears (14) and the medium thickness washers on each side of the planetary gear. Fit the three pins (12). Using a set of feeler gauges, determine the thickness of washers to be fitted to obtain an end play of between 0.15 and 0.55 on each planetary gear.

Pull out the three pins slightly and fit the shims selected in

procedure. Push in the three pins and fit the circlip (11). Open out the

circlip (11). Tap lightly on the three pins to insert the circlip (11)

into the groove in the planetary carrier. Check that the spur washer (9)

is fitted. Refit the planetary carrier. Fit shims to obtain the required

preload. Refit the trumpet housing.

Bearings and Seats

Disassembly

Separate the trumpet housing from the center housing. Remove the

planetary carrier. Remove: the spur washer (9), bearing cone (runs free

on shaft). Withdraw the shaft (2) from the trumpet housing. Extract the

cone (5A). Drive out the triple lip seal. Using an extractor, remove:

cup (5), housing (4) for seal, cup (8). Drive out the seal.

Reassembly

The planetary ring gear (22) is a tight fit in the trumpet housing. It

is centered by the three locating dowels (21) and tightened by the three

bolts (17) to a torque of 79-90 Nm (Loctite 242). Clean the seal contact

surfaces, the cup seats and the cones in the trumpet housing and on the

shaft. The seal, cup and cone contact surfaces must be free from burrs

and damage. Coat the outside diameter of the seal with Loctite 542

(metal cage).

Fit the seal the correct way round. Replacement of seal: Without replacing the shaft (2) - So that the seal lip is not in the same place on the shaft, press on the seal until it is 4 mm from the shoulder of the cup (8). Replacing the shaft (2) - Position the seal 5 mm from the shoulder of the cup (8). Lubricate the cups (8) and (5) and press them fully on to the shoulder. Press the housing (4) fully on to the shoulder.

Push the triple lip seal up against the shaft shoulder. Ensure that the seal is fitted the correct way round. Lubricate the shaft (2) and press the cone (5A) against the shoulder. Lightly grease the cone (5A) and the lips of seals (use BP Agricharge or an equivalent- grease). Protect the splines of the shaft (2) and insert it into the trumpet housing. The lips of seal must face outwards. Remove the protection from the shaft and lightly lubricate the cone (8A).

Refit the cone (8А), the washer and the planetary carrier (10). Fit

shims to obtain the required preload. Replace the plug (28) by a grease

nipple. Partly fill the cavity at the end of the trumpet housing between

the cone (5A) and the seal with BP Agricharge or an equivalent grease.

Remove the grease nipple and refit the plug. Refit the trumpet housing.

Massey Ferguson 3050, 3060, 3065, 3080 - Axle

shaft bearings preload

Place the trumpet housing assembly in a vertical position. Remove the

bolt (24) and the washer (25). Seat the cones (5A) and (8A) in their

cups by turning the trumpet housing on its shaft. Fit shims required to

provide thickness greater than dimension X to obtain end play. Fit the

washer (25) and the bolt (24) and tighten to a torque of 270-440 Nm.

Using a dial gauge, check the end play by moving the planetary carrier

laterally. Remove the bolt (24) and the washer (25). On the basis of the

reading obtained, remove the number of shims required to obtain a

preload of: P1 = 0.025 to 0.125. Clean the threads at the end of the

shaft (2). Refit the washer (25). Clean the bolt (24) and coat it with

Loctite 241. Tighten to a torque of 270-440 Nm.

Rear wheel stud replacement

Drive out the damaged stud using a hammer and bronze drift. Clean the

marks left by the stud ridges with a paint brush dipped in solvent. Dry

with compressed air. Apply a few drops of Loctite 270 to the new stud

ridges. Place the new stud in the ridge marks left by the old stud. Make

sure that the ridges are properly engaged and then knock the stud head

up against the half shaft flange with a bronze mallet.

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF FRONT END LOADERS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS MAINTENANCE |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS TROUBLESHOOTING | ||||

| 1652 | 1749 | 2620 | 2725 | 2805 |

| 3050 | 3120 | 3640 | 3709 | 4245 |

| 4455 | 5320 | 5455 | 5613 | 6150 |

| 6280 | 6480 | 6615 | 7618 | 7720 |

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS 130

130 133

133 145

145 155

155 158

158 165

165 175

175 185

185 188

188 230

230 254

254 254S

254S 284S

284S 294

294 353

353 290

290 362

362 375

375 390

390 398

398 399

399 590

590 690

690 1010

1010 1030

1030 1020

1020 1150

1150 2620

2620 2640

2640 2645

2645 1540

1540 2660

2660 3065

3065 3095

3095 3650

3650 3680

3680 4255

4255 4355

4355 4370

4370 3630

3630 3635

3635 4245

4245 4445

4445 4609

4609 4710

4710 5435

5435 5475

5475 5610

5610 5711

5711 6150

6150 6170

6170 6180

6180 6270

6270 6290

6290 6445

6445 6499

6499 6614

6614 6713

6713 7465

7465 7495

7495 7614

7614 7622

7622 7715

7715 7726

7726 8210

8210 8270

8270 8650

8650 8727

8727 GC1705

GC1705 1464 Loader

1464 Loader 1466 Loader

1466 Loader 1040 Loader

1040 Loader 1070 Loader

1070 Loader 905 Loader

905 Loader 906 Loader

906 Loader 915 Loader

915 Loader 916 Loader

916 Loader 921 Loader

921 Loader 926 Loader

926 Loader 931 Loader

931 Loader 933 Loader

933 Loader 936 Loader

936 Loader 938 Loader

938 Loader 939 Loader

939 Loader 940 Loader

940 Loader 941 Loader

941 Loader 945 Loader

945 Loader 946 Loader

946 Loader 948 Loader

948 Loader 949 Loader

949 Loader 950 Loader

950 Loader 951 Loader

951 Loader 955 Loader

955 Loader 956 Loader

956 Loader 958 Loader

958 Loader 960 Loader

960 Loader 961 Loader

961 Loader 965 Loader

965 Loader 966 Loader

966 Loader 968 Loader

968 Loader 975 Loader

975 Loader 976 Loader

976 Loader 978 Loader

978 Loader 985 Loader

985 Loader FL.3114 X

FL.3114 X FL.3419 X

FL.3419 X FL.3522

FL.3522 FL.3615

FL.3615 FL.3619

FL.3619 FL.3817

FL.3817 FL.3819

FL.3819 FL.3823

FL.3823 FL.4018

FL.4018 FL.4121

FL.4121 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader FL.4125

FL.4125 FL.4227

FL.4227 FL.4124

FL.4124 FL.4220

FL.4220 FL.4323

FL.4323 FL.4327

FL.4327 FL.4621

FL.4621 FL.4624

FL.4624 FL.4628

FL.4628 FL.5033

FL.5033 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader 1010

1010 1020

1020 1030

1030 1035

1035 1040

1040 1045

1045 1080

1080 1085

1085 1120

1120 1125

1125 1140

1140 1160

1160 1165

1165 1180

1180 1190

1190 1205

1205 1210

1210 1215

1215 1220

1220 1225

1225 1230

1230 1233

1233 1235

1235 1240

1240 1260

1260