________________________________________________________________________________

Massey Ferguson 5465, 6465, 6475, 6485 - Carraro front axle differential

Splitting the front axle and frame - Drain the axle housing. Disconnect

the axle and its bearings from the front frame. Removing the wheel hubs,

axle beam assembly and steering ram - Remove the wheel hubs. Remove the

axle beam assembly. Remove the steering ram.

MF 5465, 6465, 6475, 6485 - Dismantling the

differential housing assembly

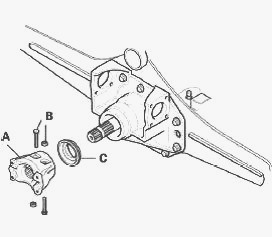

Remove screw B with its nut from flange A. Extract the flange and

recover the seal C. This will destroy the seal. Loosen and remove the

screws from the differential housing. Remove the differential housing.

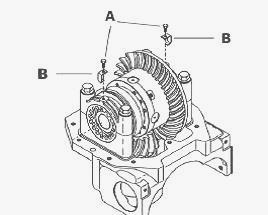

Hold the differential housing in place with a sling or other suitable

device. Loosen and remove screws A to extract the two nut retainers B.

Before removing the screws, make indelible marks to mark the position of

the two half-bearings and the differential housing to avoid reassembling

the wrong way round. Also mark the area between the nuts and the

differential housing. Loosen the adjusting ring nuts. As the two nuts

are different, mark their position relative to the bevel ring gear.

Remove the 4 screws A and the two half-bearings B. Check that rings C

stay in place in their seatings.

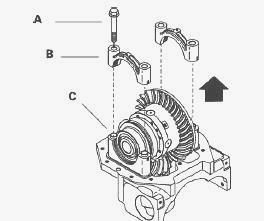

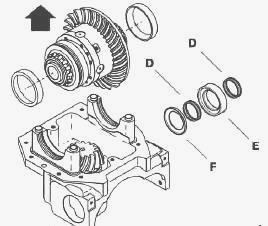

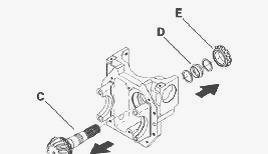

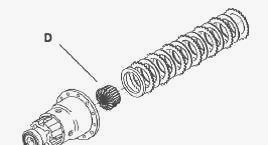

Remove the differential unit. From the ring gear side, remove and

recover spacer E with its set of rings D, washer F and the bearings

removed with the differential unit. Be careful not to invert the

bearings if they need to be reinstalled.

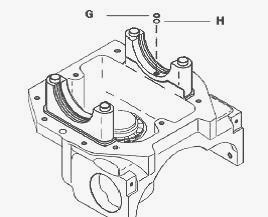

Recover washer G and "O" ring H from the bearing seating on the side of

the epicyclic ring gear.

Massey Ferguson 5465, 6465, 6475, 6485 -

Dismantling the pinion assembly

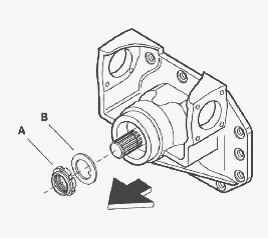

Install the differential assembly in a vice. Loosen the locknut. This

will irreparably destroy the nut. Extract nut A and recover retaining

washer B. Extract bevel gear C using a hammer. Ensure that the pinion

does not fall out. Recover the washers, flexible spacer D and internal

cone E from the tapered roller bearing.

Place the differential housing on a level surface and extract the

external cups from the roller bearing, using a drift or a hammer. Remove

the inside cone of the pinion's tapered roller bearing using a standard

puller. Recover the bearing cone and the shim located underneath it.

Check all the pinion parts for wear. The ring nut and the flexible

spacer must be replaced when refitting the assembly.

MF 5465, 6465, 6475, 6485 - Dismantling the

differential assembly

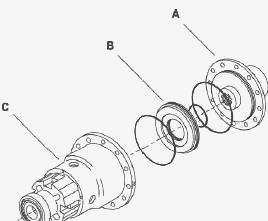

Recover the differential and secure it in a vice. Loosen the screws and

remove the bevel ring gear. This operation releases the two

half-bearings from the differential. Ensure that the internal parts do

not fall out. Detach cover plate A from differential unit C, then

extract piston B. Recover the "O" rings from the cover plate and the

differential lock piston (internal and external housings).

Remove the plates, drive discs and sun gear D from the differential

unit. Disassemble the parts that have been removed and examine them

carefully, checking in particular for wear and ensuring that they are

functioning correctly.

Use a fine punch to extract the locating pin in order to remove the long

pin. Disassemble the planet carrier and recover the parts it contains:

planet gears, thrust washers, spider, sun gear. Check all parts for wear

and ensure they are functioning correctly. Extract the bearings from the

half-bearings and the cover plate using a three-point puller.

Massey Ferguson 5465, 6465, 6475, 6485 -

Install the pinion assembly

Place the differential housing on a workbench. Install the external cups

for the new bearings. To measure the distance, use special tool kit.

Insert the dummy pinion with its bearings and nut in the newly installed

roller bearing. Tighten without forcing to eliminate the backlash.

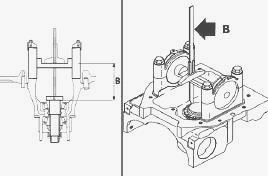

Install tools on the differential housing supports and tighten the

half-bearing screws. Assembly diagram for tools on the differential

housing supports. Using a depth gauge, measure distance B (between the

bearing pin and the bearing point of the pinion head or bearing base).

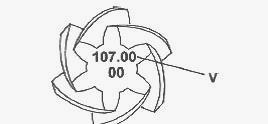

To determine the necessary thickness S between the pinion and the

bearing, subtract the value V engraved on the pinion head (V = specified

taper distance) from the measured value B: S = B - V. Select the

required thickness S from the range of shims available and insert the

chosen shim under the pinion head. Ensure that it is fitted correctly.

After inserting the correct shim with its chamfer facing the pinion,

force Install the bearing at the end of the pinion pin using special

tool and a press, ensuring that it is seated correctly. Install the

shims and a new flexible spacer. Systematically Install a new flexible

spacer. Insert the bevel gear assembly into the differential housing

(axle beam internal side) and the second bearing cone at the end of the

pinion, on the opposite side. Force Install the second bearing. It is

recommended that you exert resistance against the striking action of the

tool, by using a hammer for example.

Place a retaining washer and screw a new nut onto the end of the pinion.

Screw the nut on with the wrench while holding the pinion in place with

the tool. The tightening torque is determined by the bearing preload

measurement. Gradually tighten the nut. If too much tightening torque is

applied, replace the flexible spacer and restart the operation. When

checking bearing preload, it is advisable to gently tap both ends of the

pinion with a rubber hammer to make the bearing seating easier. Measure

the torque P of the tapered roller bearings of the pinion. Shimming is

carried out by gradually increasing the tightening torque of the nut,

taking care not to exceed the recommended value. All torques must be

measured without the seal. P = 1.82 to 2.72 Nm. When the torque value is

reached, peen the nut with a hammer and chisel.

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF FRONT END LOADERS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS MAINTENANCE |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS TROUBLESHOOTING | ||||

| 1652 | 1749 | 2620 | 2725 | 2805 |

| 3050 | 3120 | 3640 | 3709 | 4245 |

| 4455 | 5320 | 5455 | 5613 | 6150 |

| 6280 | 6480 | 6615 | 7618 | 7720 |

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS 130

130 133

133 145

145 155

155 158

158 165

165 175

175 185

185 188

188 230

230 254

254 254S

254S 284S

284S 294

294 353

353 290

290 362

362 375

375 390

390 398

398 399

399 590

590 690

690 1010

1010 1030

1030 1020

1020 1150

1150 2620

2620 2640

2640 2645

2645 1540

1540 2660

2660 3065

3065 3095

3095 3650

3650 3680

3680 4255

4255 4355

4355 4370

4370 3630

3630 3635

3635 4245

4245 4445

4445 4609

4609 4710

4710 5435

5435 5475

5475 5610

5610 5711

5711 6150

6150 6170

6170 6180

6180 6270

6270 6290

6290 6445

6445 6499

6499 6614

6614 6713

6713 7465

7465 7495

7495 7614

7614 7622

7622 7715

7715 7726

7726 8210

8210 8270

8270 8650

8650 8727

8727 GC1705

GC1705 1464 Loader

1464 Loader 1466 Loader

1466 Loader 1040 Loader

1040 Loader 1070 Loader

1070 Loader 905 Loader

905 Loader 906 Loader

906 Loader 915 Loader

915 Loader 916 Loader

916 Loader 921 Loader

921 Loader 926 Loader

926 Loader 931 Loader

931 Loader 933 Loader

933 Loader 936 Loader

936 Loader 938 Loader

938 Loader 939 Loader

939 Loader 940 Loader

940 Loader 941 Loader

941 Loader 945 Loader

945 Loader 946 Loader

946 Loader 948 Loader

948 Loader 949 Loader

949 Loader 950 Loader

950 Loader 951 Loader

951 Loader 955 Loader

955 Loader 956 Loader

956 Loader 958 Loader

958 Loader 960 Loader

960 Loader 961 Loader

961 Loader 965 Loader

965 Loader 966 Loader

966 Loader 968 Loader

968 Loader 975 Loader

975 Loader 976 Loader

976 Loader 978 Loader

978 Loader 985 Loader

985 Loader FL.3114 X

FL.3114 X FL.3419 X

FL.3419 X FL.3522

FL.3522 FL.3615

FL.3615 FL.3619

FL.3619 FL.3817

FL.3817 FL.3819

FL.3819 FL.3823

FL.3823 FL.4018

FL.4018 FL.4121

FL.4121 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader FL.4125

FL.4125 FL.4227

FL.4227 FL.4124

FL.4124 FL.4220

FL.4220 FL.4323

FL.4323 FL.4327

FL.4327 FL.4621

FL.4621 FL.4624

FL.4624 FL.4628

FL.4628 FL.5033

FL.5033 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader 1010

1010 1020

1020 1030

1030 1035

1035 1040

1040 1045

1045 1080

1080 1085

1085 1120

1120 1125

1125 1140

1140 1160

1160 1165

1165 1180

1180 1190

1190 1205

1205 1210

1210 1215

1215 1220

1220 1225

1225 1230

1230 1233

1233 1235

1235 1240

1240 1260

1260