________________________________________________________________________________

Massey Ferguson 5465, 6465, 6475, 6480 - Carraro final drive unit

Before draining the oil, position the wheel hub with the plug at its

highest point and loosen the plug by several turns to release any

internal residual pressure, then loosen it completely. Turn the hub

again to position the plug at its lowest point. Completely drain the

oil. Loosen and remove the two planet carrier screws using a wrench.

Extract the planet carrier from the wheel hub. Place the planet carrier

on a workbench and check it for wear.

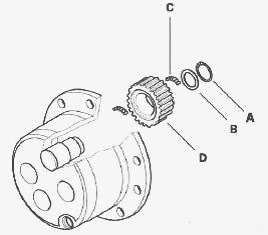

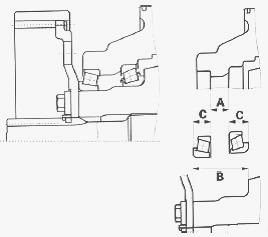

Replace the planet gears as necessary: extract circlip A from each

planet gear, remove washer B and extract planet gears D from their pins,

recover bearings C and check their condition. It is recommended that you

replace the bearings when installing new planet gears.

Wheel hub disassembly

Before disassembling the wheel hub, it is recommended that you attach it

with a belt or sling to a hoist or other suitable lifting device to

prevent it from falling accidentally, risking injury to the operator and

damage to the wheel hub. Some of the following illustrations may show

axles that differ slightly from your model, but the procedure is the

same. Insert a lever between the swivel housing and slide it into the

universal joint. Push on the joint with the lever in the direction of

the final drive to remove the circlip more easily. Remove and discard

the circlip. Remove and discard the washer. Remove and discard the two

star washers. Loosen and remove the screws from the ring gear carrier

assembly. To remove the ring gear assembly from its housing, screw at

least two of the screws that have just been removed into the threaded

extraction holes. While keeping an eye on the ring gear ports, avoid

positioning the screws on the cast iron notches.

Remove the ring gear carrier with the epicyclic ring gear. Remove the

snap ring and detach the ring gear carrier from the epicyclic ring gear.

Check the condition of the parts. If necessary, remove the locating

rings from the locking ring gear of the hub using a hammer and special

tool. Remove the wheel hub using levers and a hammer to facilitate the

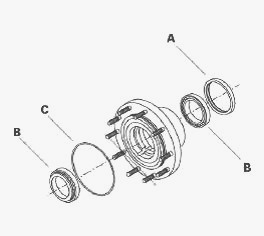

operation. Recover the bearing cone. Place the wheel hub on a level

surface and extract the seal ring (A) with a lever. This will destroy

the seal ring. Remove bearing cups B from either side of the hub using a

hammer and a suitable puller. Remove the bearing cone from the swivel

housing side using a suitable puller. Remove the "O" ring C from the

wheel hub.

Loosen and remove the screws from the upper and lower pivot pins. Before

removing the pivot pins, attach the swivel housing to a hoist or other

suitable lifting device with a belt or sling. Remove the pivot pins and

recover the Belleville washers. Mark the positioning of the two

Belleville washers, which are not identical. Remove the swivel housing

from the axle beam and the short shaft of the universal joint shaft.

Place the swivel housing on a level surface and extract the seal ring

with a lever. This will destroy the seal ring. Turn the swivel housing

to extract the ring using a drift and a hammer.

Massey Ferguson 5465, 6465, 6475, 6480 -

Dismantling the axle beam assembly

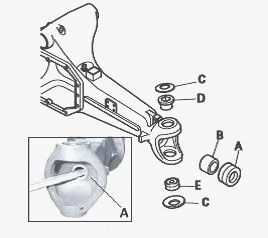

Separate the universal joint shaft from the axle beam. Extract seal ring

A from the axle beam with a lever. Remove the Belleville washers C from

the pivot pin housings inside the axle beam. Mark the positioning of the

two Belleville washers, which are not identical. This will destroy the

seal ring. Extract ring B from the axle beam using a suitable puller.

Check the ring before reassembling and only replace it if its state of

wear requires this. Extract the upper rings D and lower rings E from the

pivot pin housings F and pivot pins using a suitable puller. Extract the

nut and retaining washer from the taper pin. Remove the pin using a

hammer. Remove the pivot pin using a hammer or other soft object if

necessary.

MF 5465, 6465, 6475, 6480 - Reassembling the

axle beam assembly

Install the ring of the upper pivot pin on the axle beam using special

tool and a hammer. Insert the roller bearing cup on the lower part of

the axle beam using special tool and a hammer. Cool the arm pins to

under -100C before installing them in order to facilitate their

assembly. This can be achieved by completely immersing the arm pins in

liquid nitrogen. To purchase or hire liquid nitrogen, contact the

company "Air Liquide". It is advisable to wear protective gloves.

Install the ring on the axle beam using special tool and a hammer.

Install the seal on the axle beam. Fill the seal seating three quarters

full with grease. Lubricate the ring and the lip of the seal. Insert the

universal joint shaft into the axle beam.

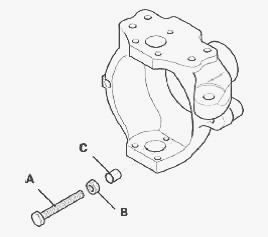

Reassembling the wheel hub assembly

Position screw A, nut B and washer C. If washer C is not fitted, the

axle will be damaged.

Force Install the ring in the swivel housing. Install the seal on the

swivel housing. Fill the seal seating three quarters full with grease.

Place the lower pivot pin on a workbench and install the ball joint cone

and a press. Apply a generous amount of grease to the pivot pin

housings. Install the Belleville washers on the pivot pin housings.

Attach the swivel housing assembly with a sling. Lubricate the seal lip

and protect the splined end of the shaft by wrapping adhesive tape

around it to protect the seal from damage. After assembly, completely

remove the adhesive tape. Install the swivel housing on the axle beam.

Install the two pivot pins, one upper and one lower, and tighten the

screws to the required torque using a torque wrench. Ensure that the

Belleville washers remain in place.

The special "Set Right" operation, which consists of shimming the

bearings, does not require any specific preload or setting. The required

values should always be checked before installing new parts. A = 08.450

to 08.500 mm. B = 54.775 to 54.825 mm. C = 23.070 to 23.172 mm.

Place the wheel hub on a workbench and install the two tapered roller

bearing cups and a press or hammer. Insert the lip seal into the wheel

hub. Install the bearing cone at the end of the pivot pin. Assemble the

hub on the pivot pin and fit the second bearing cone. Place the ring

gear carrier on a workbench and ensure that the rings are flush with the

ring gear carrier surface. The two rings must be positioned slightly

higher than the ring gear carrier surface to act as guide pins.

Pre-position the assembly consisting of the ring gear carrier and the

epicyclic ring gear with special snap ring.

Install the ring gear carrier assembly on the wheel hub using the two

shouldered rings as guide pins and tighten the corresponding screws

until the ring gear comes into contact with the wheel hub. Do not use

the two screws that were used to remove the ring gear assembly from its

housing when disassembling. Force Install all the rings. Install the

ring gear carrier screws and tighten to the required torque. Insert a

lever between the swivel housing and slide it into the universal joint.

Push on the joint with the lever in the direction of the final drive to

remove the shaft and facilitate reassembly of the circlip. Install two

new star washers on the shaft. Check that the two washers are correctly

positioned. Install a new washer, positioning it so that the groove

faces outwards. Install the snap ring. Take care not to damage it during

assembly. Carefully push the universal joint and ensure that the circlip

is correctly positioned in the groove of the washer.

Massey Ferguson 5465, 6465, 6475, 6480 -

Reassembling the final drive assembly

Recover all final drive parts. Place the planet carrier on a workbench.

Into the planet carrier pins insert: the lower bearings, the planet

gears and then the upper bearings. Install the thrust washers with their

circlips. Using a torque wrench, tighten the screws to the required

torque. Install a new "O" ring on the wheel hub. Install the final drive

on the hub. Using a torque wrench, tighten the screws to the required

torque.

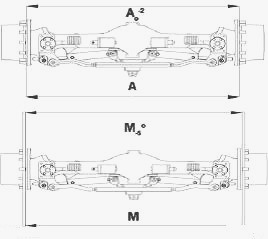

Wheel alignment

Place two identical straight bars, each one metre long, along the sides

of the ring gear and lock them on the wheel hub stud using two nuts.

Measure the distance M in mm between the ends of the bars. Keep the

minimum value by oscillating the measurement point.

Ensure that the deviation in measurement A between the ends of the wheel

hub diameters does not exceed the permissible values. Measured value M

taken at the ends of the bars must depend on the ratio between the

length of the bar and the diameter of the flange: Alignment (see chapter

8) = A0-2. Measurement deviation = M0-5. If the alignment is not

correct, adjust the selector rails by screwing or unscrewing both tie

rods equally, using two wrenches, until the alignment is within the

permitted values. Once adjustment is complete, screw the locknuts of the

selector rails to the required torque.

Adjusting the steering angle

Use the bars fitted to adjust alignment and a long bar pressing against

the machined part of the central body (gear side) so that the two bars

form an acute angle corresponding to the maximum steering lock position.

Adjust the goniometer to the required steering angle and position it on

the long bar. Move one side of the ring gear to obtain the angle defined

by the goniometer and formed by the ring gear and the long bar. Adjust

the mechanical steering stop by tightening or loosening the special

screws, then lock them to the required torque using the counter-nut.

Lock steering in the other direction and repeat this procedure.

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF FRONT END LOADERS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS MAINTENANCE |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS TROUBLESHOOTING | ||||

| 1652 | 1749 | 2620 | 2725 | 2805 |

| 3050 | 3120 | 3640 | 3709 | 4245 |

| 4455 | 5320 | 5455 | 5613 | 6150 |

| 6280 | 6480 | 6615 | 7618 | 7720 |

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS 130

130 133

133 145

145 155

155 158

158 165

165 175

175 185

185 188

188 230

230 254

254 254S

254S 284S

284S 294

294 353

353 290

290 362

362 375

375 390

390 398

398 399

399 590

590 690

690 1010

1010 1030

1030 1020

1020 1150

1150 2620

2620 2640

2640 2645

2645 1540

1540 2660

2660 3065

3065 3095

3095 3650

3650 3680

3680 4255

4255 4355

4355 4370

4370 3630

3630 3635

3635 4245

4245 4445

4445 4609

4609 4710

4710 5435

5435 5475

5475 5610

5610 5711

5711 6150

6150 6170

6170 6180

6180 6270

6270 6290

6290 6445

6445 6499

6499 6614

6614 6713

6713 7465

7465 7495

7495 7614

7614 7622

7622 7715

7715 7726

7726 8210

8210 8270

8270 8650

8650 8727

8727 GC1705

GC1705 1464 Loader

1464 Loader 1466 Loader

1466 Loader 1040 Loader

1040 Loader 1070 Loader

1070 Loader 905 Loader

905 Loader 906 Loader

906 Loader 915 Loader

915 Loader 916 Loader

916 Loader 921 Loader

921 Loader 926 Loader

926 Loader 931 Loader

931 Loader 933 Loader

933 Loader 936 Loader

936 Loader 938 Loader

938 Loader 939 Loader

939 Loader 940 Loader

940 Loader 941 Loader

941 Loader 945 Loader

945 Loader 946 Loader

946 Loader 948 Loader

948 Loader 949 Loader

949 Loader 950 Loader

950 Loader 951 Loader

951 Loader 955 Loader

955 Loader 956 Loader

956 Loader 958 Loader

958 Loader 960 Loader

960 Loader 961 Loader

961 Loader 965 Loader

965 Loader 966 Loader

966 Loader 968 Loader

968 Loader 975 Loader

975 Loader 976 Loader

976 Loader 978 Loader

978 Loader 985 Loader

985 Loader FL.3114 X

FL.3114 X FL.3419 X

FL.3419 X FL.3522

FL.3522 FL.3615

FL.3615 FL.3619

FL.3619 FL.3817

FL.3817 FL.3819

FL.3819 FL.3823

FL.3823 FL.4018

FL.4018 FL.4121

FL.4121 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader FL.4125

FL.4125 FL.4227

FL.4227 FL.4124

FL.4124 FL.4220

FL.4220 FL.4323

FL.4323 FL.4327

FL.4327 FL.4621

FL.4621 FL.4624

FL.4624 FL.4628

FL.4628 FL.5033

FL.5033 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader 1010

1010 1020

1020 1030

1030 1035

1035 1040

1040 1045

1045 1080

1080 1085

1085 1120

1120 1125

1125 1140

1140 1160

1160 1165

1165 1180

1180 1190

1190 1205

1205 1210

1210 1215

1215 1220

1220 1225

1225 1230

1230 1233

1233 1235

1235 1240

1240 1260

1260