________________________________________________________________________________

Massey Ferguson 5465, 6465, 6475, 6480 - Carraro front axle transmission shaft bearings

The MF 5465, 6465, 6475, 6480 tractors are fitted with a fixed Carraro

front axle. Drive is transmitted from the front axle clutch located in

the rear axle via a transmission shaft. On 6-cylinder tractor engine

models, the transmission shaft has a universal joint and the front axle

pivot is raised. The shaft is divided into two sections. The section

linked to the 4WD unit by a sleeve is fixed.

The front part of the tractor transmission shaft has a universal joint,

allowing the axle to oscillate on its raised pin. The two sections of

the transmission shaft are linked by a castellated nut (11) and

supported by a bearing (6) at gearbox level. The front frame supports

the front axle pivot. The pivot front bearing is removable on all

models, while the rear bearing is part of the front frame assembly.

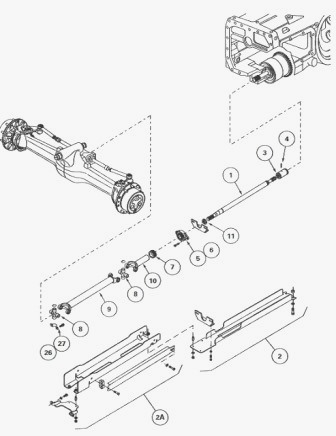

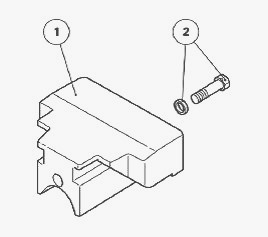

Parts list (Carraro 20.19 front axle) - (1) Straight

shaft (2) Guard (2A) Guard (3) Sleeve (4) Screw (5) Central bearing (6)

Bearing (7) Dust seal nut (8) Spider (9) Shaft (10) Sleeve (11)

Castellated locknut (12) Front frame (13) Chamfered washer (14) Washer

(15) Front bearing (16) Seal (17) Ring (18) Ring (19) Plug (20) Circlip

(21) Screw (22) Front axle (23) Grease nipple (24) Union (25)

Lubrication pipe (26) Flanges (27) Screw

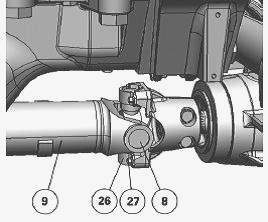

MF 5465, 6465, 6475, 6480 - Disassembling and

reassembling the 4WD transmission shafts and the universal joint spiders

Disassembling the universal joint shaft - Chock the rear wheels and

apply the hand brake. Remove the guards (2) (2A). Unscrew the dust seal

nut (7). Remove the screws (27) and the flanges (26). Move the universal

joint shaft (9) and spider (8) assembly away from the drive pinion

carrier. Remove the shaft. If there is not enough room to push the

universal joint shaft backwards for removal, disassemble the central

bearing and the straight shaft (1). The spiders are replaceable. They

are listed in the parts book.

If the spiders need to be replaced, carefully check the condition of the

end clevises where the spider catches are located. Remove any traces of

impact or sharp edges. Thoroughly clean the groove of each circlip.

After assembly, check that the circlips are properly positioned in their

respective grooves. If necessary, and to facilitate mounting of the

universal joint shaft on the drive pinion carrier, raise the front

wheels using a jack with sufficient lifting capacity, positioned along

the axis of the axle housing.

Replace the dust seal nut (7). Use a makeshift tapered tool to refit the

dust seal nut (7) on the shaft (1). Smear the front splines of the

straight shaft with molybdenum sulphide grease or equivalent. Refit the

universal joint shaft (9). Attach the front spider (8) to the plate of

the drive pinion carrier using the flanges (26) and washer-head screws

(27) that have been lightly smeared with Loctite 241 or equivalent and

tightened to a torque of 34-41 Nm. Moderately tighten the dust seal nut

(7). Using a grease gun, lubricate the sleeve (10) and refit the guards

(2) and (2A).

Massey Ferguson 5465, 6465, 6475, 6480 -

Straight shaft and bearing

Disassembling - Remove the guards (2) (2A) and the universal joint shaft

assembly. Remove the screw (4) and slide the sleeve (3) towards the

front of the straight shaft. Remove the central bearing (5), bearing (6)

and straight shaft (1) assembly. Separate the support (5) from the

bearing (6). Unscrew the castellated nut (11) using a suitable wrench.

Remove the bearing from the straight shaft.

Reassembling - Check the parts. Replace those that are defective.

Install bearing (6) on the straight shaft with the offset turned

rearwards. Tighten the nut with a suitable wrench. Assemble the support

(5) on the bearing (6). Tighten the screws. Reinstall the central

bearing, bearing (6) and straight shaft (1) assembly. Smear the rear

splines of the straight shaft (1) with molybdenum sulphide grease or

equivalent. Slide the sleeve (3) towards the rear of the straight shaft.

Refit the screw (4). Replace it if it is in a poor condition. Reinstall

the universal joint shaft assembly. Reinstall the guards (2) (2A).

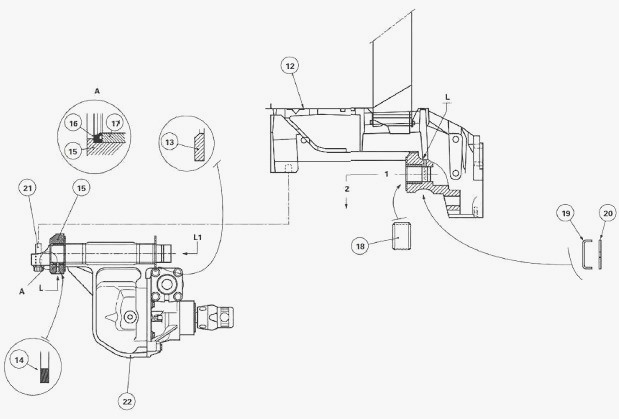

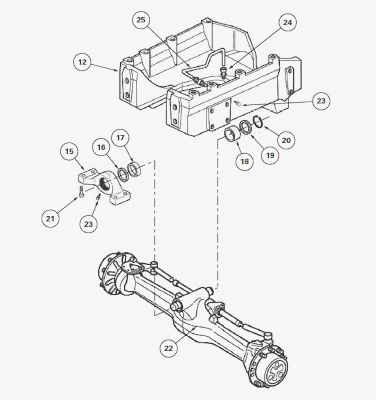

Massey Ferguson 5465, 6465, 6475, 6480 -

Removing and install the bearing support and Carraro front axle

Remove the 45 kg front weights (if fitted). Immobilise the MF 5465,

6465, 6475, 6480 tractor. Apply the hand brake. Place safety chocks on

either side of the rear wheels. Some tractors may be fitted with a front

power take-off. In this case, it will be necessary to remove it in order

to separate the front axle from the frame (12). In certain conditions,

the centre weight (1) of 100 kg may obstruct the removal of the bearing

support. For this configuration, strip out the internal parts at the

lower part of the grille to gain access to the weight. Take out the

central M20 screw (2) and lift the weight slightly using a suitable

lifting tool to release it from the support.

Removing the support (15) and the front axle. Remove the guards (2)

(2A). Raise the tractor along the axis of the front axle housing using a

jack with sufficient lifting capacity. Remove the front wheels. Mark the

steering hoses connection and detach them from the ram. Disconnect the

front differential lock control hose. Sling the front axle using

suitable straps. Remove the screws (21). Pull the front axle assembly

complete with bearing support (15) forwards along the axis of the axle

beam (position 1) and remove the front axle (position 2). Note the

features, order and position of the washers (13) (14) and the direction

of the chamfers and remove them.

Clean all components and check the condition of: the pivot pin at each

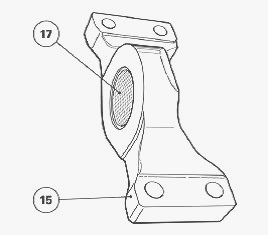

end, the washers (13) (14), the friction rings (17) (18), the seal (16).

Slide the washers (13) (14) lightly smeared with bearing grease onto the

front and rear ends of the pivot pin. Position the washers in the order.

Sling the front axle. Moderately lubricate the ends of the pivot pin and

Install the support (15) at the front of the pivot pin. Before refitting

the front axle assembly, check that there is no excess grease in the

cavity of the second axle beam pivot on the front frame.

When refitting the front axle assembly, any such excess grease will be

compressed, and may hinder insertion of the pivot pin into its bearing.

Reinstall the front axle and support (15) assembly. Push the assembly

hard until it comes into contact with the second axle beam pivot. Thrust

the support (15) against the front axle assembly (22) to eliminate the

clearance between supports and axle housing as much as possible. Install

the screws lightly smeared with Loctite 270 or equivalent and tighten to

a torque of 520-640 Nm.

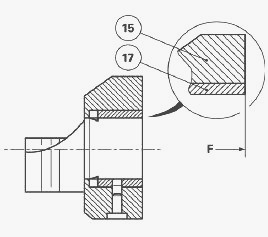

Check that the front face of the pivot pin is almost level with the

front edge "F" of the bearing support (15). Visually check for the

presence of the grease nipple on the left-hand side of the front frame

(12) (second axle beam pivot) and on the support (15) (first axle beam

pivot). Reconnect the hoses (using marks made during disassembly): of

the steering ram, of the front differential lock. Reinstall the wheels.

Remove the axle stand and take away the jack. Tighten the nuts to a

torque of 640-680 Nm. Reinstall the centre weight. Tighten the central

screw to a torque of 100-150 Nm and secure the front weights (depending

on equipment fitted). Reinstall the universal joint shaft and the

guards. Remove the safety chocks and release the hand brake. Using a

grease gun, lubricate the friction rings (17) (18) of the axle beam

pivots.

MF 5465, 6465, 6475, 6480 - Replacing the

friction rings and seal

Front bearing

Disassembling - Only remove the bearing support (15). Extract and

discard the ring (17). Drive out and discard the seal (16).

Reassembling - Clean and check all components. Replace those that are

defective. Check that the lubrication lines in the support are not

blocked.

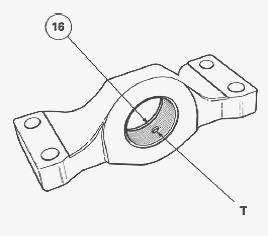

Using a press and a suitable fixture, Install the seal (16), positioned

correctly, and the ring (17) level with face "F" of the support (15),

with the lubrication port "T" connecting with the line.

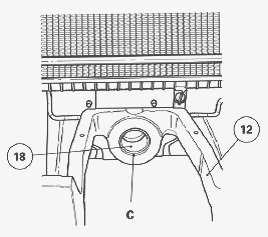

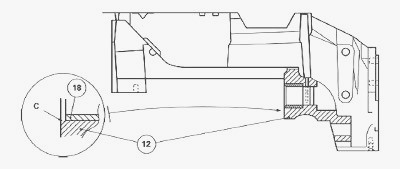

To work on the ring (18) of the second axle beam pivot, the first axle

beam pivot and the front axle must be removed.

Rear bearing

Disassembling - Drive out the ring (18) using a makeshift tool. The

circlip (20) and the plug (19) are not considered to be wearing parts.

It is therefore unlikely that they will need replacing.

Reassembling - Using a makeshift fitting drift, Install the ring (18)

onto the frame (12) level with the chamfer "C".

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF FRONT END LOADERS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS MAINTENANCE |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS TROUBLESHOOTING | ||||

| 1652 | 1749 | 2620 | 2725 | 2805 |

| 3050 | 3120 | 3640 | 3709 | 4245 |

| 4455 | 5320 | 5455 | 5613 | 6150 |

| 6280 | 6480 | 6615 | 7618 | 7720 |

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS 130

130 133

133 145

145 155

155 158

158 165

165 175

175 185

185 188

188 230

230 254

254 254S

254S 284S

284S 294

294 353

353 290

290 362

362 375

375 390

390 398

398 399

399 590

590 690

690 1010

1010 1030

1030 1020

1020 1150

1150 2620

2620 2640

2640 2645

2645 1540

1540 2660

2660 3065

3065 3095

3095 3650

3650 3680

3680 4255

4255 4355

4355 4370

4370 3630

3630 3635

3635 4245

4245 4445

4445 4609

4609 4710

4710 5435

5435 5475

5475 5610

5610 5711

5711 6150

6150 6170

6170 6180

6180 6270

6270 6290

6290 6445

6445 6499

6499 6614

6614 6713

6713 7465

7465 7495

7495 7614

7614 7622

7622 7715

7715 7726

7726 8210

8210 8270

8270 8650

8650 8727

8727 GC1705

GC1705 1464 Loader

1464 Loader 1466 Loader

1466 Loader 1040 Loader

1040 Loader 1070 Loader

1070 Loader 905 Loader

905 Loader 906 Loader

906 Loader 915 Loader

915 Loader 916 Loader

916 Loader 921 Loader

921 Loader 926 Loader

926 Loader 931 Loader

931 Loader 933 Loader

933 Loader 936 Loader

936 Loader 938 Loader

938 Loader 939 Loader

939 Loader 940 Loader

940 Loader 941 Loader

941 Loader 945 Loader

945 Loader 946 Loader

946 Loader 948 Loader

948 Loader 949 Loader

949 Loader 950 Loader

950 Loader 951 Loader

951 Loader 955 Loader

955 Loader 956 Loader

956 Loader 958 Loader

958 Loader 960 Loader

960 Loader 961 Loader

961 Loader 965 Loader

965 Loader 966 Loader

966 Loader 968 Loader

968 Loader 975 Loader

975 Loader 976 Loader

976 Loader 978 Loader

978 Loader 985 Loader

985 Loader FL.3114 X

FL.3114 X FL.3419 X

FL.3419 X FL.3522

FL.3522 FL.3615

FL.3615 FL.3619

FL.3619 FL.3817

FL.3817 FL.3819

FL.3819 FL.3823

FL.3823 FL.4018

FL.4018 FL.4121

FL.4121 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader FL.4125

FL.4125 FL.4227

FL.4227 FL.4124

FL.4124 FL.4220

FL.4220 FL.4323

FL.4323 FL.4327

FL.4327 FL.4621

FL.4621 FL.4624

FL.4624 FL.4628

FL.4628 FL.5033

FL.5033 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader 1010

1010 1020

1020 1030

1030 1035

1035 1040

1040 1045

1045 1080

1080 1085

1085 1120

1120 1125

1125 1140

1140 1160

1160 1165

1165 1180

1180 1190

1190 1205

1205 1210

1210 1215

1215 1220

1220 1225

1225 1230

1230 1233

1233 1235

1235 1240

1240 1260

1260