________________________________________________________________________________

Massey Ferguson 5445, 5455, 6460 - Dana differential

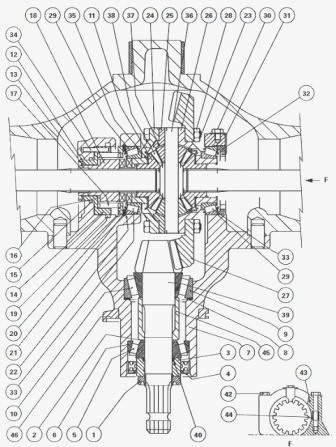

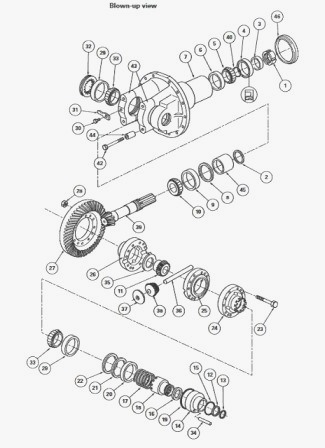

The crownwheel and pinion assembly containing the differential lock

mechanism (Hydraulic lock) is fitted in a housing (7) comprising two

half-bearings (43) fixed by screws (42). The pinion is positioned at the

rear of the housing on two opposing tapered roller bearings. It is

adjusted in position using shims (8) located behind the head bearing.

The bearings are adjusted using shims (2) inserted between the spacer

(45) (if Installed) and the bearing cone (5). Tightness is ensured by a

lip seal (4) and an "O" ring (40) fitted on the pinion. The differential

comprises two planet gears (38) and a pin (36). The ring gear/pinion

clearance is obtained using shims (22) placed behind the cup (29). The

housing and ring gear assembly preload is obtained using the spline nut

(32).

Dana differential parts list - (1) Nut (2) Shim(s) (3)

Spacer (4) Seal (5) Bearing cone (6) Bearing cup (7) Housing (8) Shim(s)

(9) Bearing cup (10) Bearing cone (11) Sun gear (12) Tab washer (13)

Snap ring (14) Piston (15) "O" ring (16) Friction washer (17) Spring

(18) Mobile dog clutch (19) "O" ring (20) Guide washer (21) Washer (22)

Shim(s) (23) Screw (24) Fixed dog clutch (25) Half-unit (26) Half-unit

(27) Ring gear (28) Nut (29) Bearing cup (30) Screw (31) Lock (32)

Spline nut (33) Bearing cone (34) Centring pin (35) Washer (36) Planet

gear pin (37) Spherical washer (38) Planet gear (39) Pinion (40) "O"

ring (42) Bearing screw (43) Half-bearing (44) Locating ring (45) Spacer

(46) Deflector

MF 5445, 5455, 6460, 6470 - Disconnecting the Dana

front axle and frame

Drain the axle housing. Disconnect the axle and its bearings from the

front frame. Removing the swivel housings, wheel hubs and transmissions.

Extract the steering ball joints. Using a suitable sling, support and

take off the complete right and left-hand swivel housing assemblies.

Removing the drive pinion carrier

Take off the swivel housing, wheel hub and transmission assemblies.

Remove the screws from the ram and remove the ram. Remove the screws.

Loosen and remove the drive pinion carrier. If necessary, remove the

deflector (46).

Massey Ferguson 5445, 5455, 5460, 6460, 6470 - Removing

the Dana differential unit

Place the housing (7) in a vice fitted with soft jaws. Take out the

screw (30) and its lock (31). Take off the spline nut (32) using the

special makeshift wrench. Take out the four screws (42). Take off the

half-bearings (43). Remove the differential assembly complete with cones

(33) and cups (29). Separate the cups from the cones. Remove the shim(s)

(22) used to adjust the backlash. Pair up the bearing cones and cups in

they are to be re-used.

Disassembling the planet gears and sun gears

Place the differential unit in a vice fitted with soft jaws. Before

disassembling, mark the position of the half-units (25) (26) and the

fixed dog clutch (24) with paint for reassembly in their initial

positions.

Removing the ring gear - Take off the screws (23) and nuts (28). Remove

the ring gear. Disassembling the planet gears and sun gears - Take off

the screws (23) and nuts (28). Separate the half-units (25) (26) and the

fixed dog clutch (24). Remove the sun gear (11) and the washer (35).

Take out the pin (36), planet gears (38) and spherical washers (37). If

required, extract the bearing cones (33) on the half-unit (26) and on

the fixed dog clutch (24).

MF 5445, 5455, 5460, 6460, 6470 - Removing the

differential lock

Using tool centred correctly, compress the spring (17) until the thrust

washer (21) is free. Take off the washer and gradually release the

spring. Take off the tool along with the guide washer (20) and spring.

Take off the snap ring (13). Remove the mobile dog clutch (18), the

friction washer (16) and the tab washer (12). Drive out the piston (14).

Discard the "O" rings (15) (19).

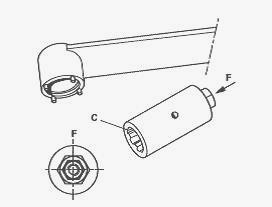

Removing the pinion

Loosen the pinion by turning clockwise, using special makeshift sleeve

"C". From the front of the housing, extract the pinion, cone (10),

spacer (45), shims (2) and "O" ring (40). Separate the pinion and seal

(40), and remove the shims (2) and the spacer (45). Extract the cone

(10) from the pinion. Drive out the cup (9) and remove the shims (8).

Remove the spacer (3), and extract the seal (4). Remove the cone (5).

Drive out the cup (6).

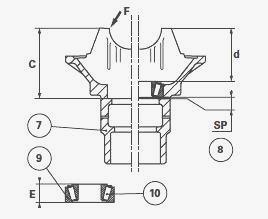

Adjusting the position – Shimming and

reinstall the pinion

Clean the components and replace those that are defective. Check that

the differential lock hydraulic channel is not blocked in the housing.

Adjust the position of the pinion. The thickness of shims required to

position the pinion correctly is calculated as follows: SP = C - E (d ±

r). SP: Thickness of shims required (8). C: Value measured between the

mating face of the cup and machined face "F". d: Pinion nominal

positioning dimension: 118 mm ± 0.10. E: Thickness of the bearings (9)

(10). r: Actual value marked on the pinion. This value may be positive

or negative (to be added or subtracted from the nominal value d). Using

a depth gauge, measure values C and E. Ensure the cone (10) is correctly

seated in the cup (9). After measuring the values, apply the formula to

determine the thickness of shims required. Install the cone (10) up

against the shoulder on the pinion (39) using a press and a suitable

fitting. Position the thickness of shims (8) calculated previously into

the housing. Install the cup (9) using a suitable fitting and shim the

bearings (5) (6) and (9) (10).

Shimming - In the housing (7), position the prepared pinion prepared up

against the cylindrical sleeve "M" as shown in pic. Press hard on the

housing while turning it several times in order to seat the bearing cone

(10) correctly in the bearing cup (9). Slide on the spacer (45), with

its chamfer facing towards the splines of the pinion.

Using a depth gauge, measure value F according to the formula A - B.

Press hard on the cup (6), turning it alternately to the right and left

to correctly seat the cone (5). Measure value G. Calculate the thickness

of shims SP1 according to the formula: G - F. Position the cup (6) up

against the housing. Slide the shims (2) calculated during step onto the

pinion. Install the cone (5) and the lubricated seal (40). Grease the

lips of the seal (4) and Install it home in the shoulder using a

makeshift drift. Install the spacer (3). Install the nut (1). Using the

special sleeve and a torque wrench, turn the pinion until the following

tightening torque is obtained: 360-400 Nm. Check the pinion rotational

torque.

Checking the pinion rotational torque: Turn the pinion several turns

using a dial-type torque wrench and the special sleeve. Check that the

rotational torque is 2 to 4 Nm. After checking the torque, take off and

degrease the nut (1) and lightly smear it with Loctite 270 or

equivalent.

Massey Ferguson 5445, 5455, 5460, 6460, 6470 - Reinstall

the differential lock

Clean and check all components. Replace those that are defective.

Install the friction washer (16) to the mobile dog clutch (18). Install

the assembly in the piston (14). Install the tab washer (12) and

position the snap ring (13) in the groove of the mobile dog clutch. In

the housing without seals, provisionally Install the piston (14) with

the mobile dog clutch (18). The pin (34) is force-fitted in the piston.

Check - Ensure that the piston and pin slide freely in the housing.

After checking, remove the piston fitted with the mobile dog clutch.

Install the new "O" rings (15) (19). Position and fit the piston and

mobile dog clutch assembly by tapping around the rim with a plastic

hammer. Position the spring (17) and washer (20) with the shoulder

turned towards the spring. Compress the assembly using tool MF 471 until

the washer (21) slides freely in the groove of the housing. Loosen the

tool carefully so that the spring does not jump out.

MF 5445, 5455, 5460 6460, 6470 - Reassembling planet

gears and sun gears

Check and clean the components. Replace any defective parts.

Reassembling planet gears and sun gears - If it is necessary to replace

the bearings (29) (33), fit a cone (33) onto the half-unit (26) and

another cone onto the fixed dog clutch (24) using a press and a suitable

fitting. Assemble the half-unit (25) in the dog clutch (24), according

to the marks made during disassembly. Position the washer (35) on the

sun gear (11) and position the assembly in the half-unit (25), while

inserting the washer tab into one of the half-unit holes. Position the

planet gears (38) and washers (37) on the pin (36). Next, position the

assembly in the half-unit (25), while turning the tabs of the washers

(37) into the holes of the half-unit (25). Install the other washer (35)

on the other sun gear (11). Install the assembly in the half-unit (26)

according to the position of the tab of the washer (35). Position the

half-unit (26) assembly on the half-unit (25) according to the marks

made during disassembly.

Reinstall the ring gear - Any replacement of the ring gear (27)

automatically entails replacing the pinion (39). The same number is

engraved onto the pinion and ring gear. They must be fitted as pairs.

Clean the mating faces of the ring gear and differential unit. Degrease

the new screws and nuts and smear the threads of each screw with Loctite

270 or equivalent. Secure the two half-units (25) (26), fixed dog clutch

(24) and ring gear using screws and nuts (28) tightened to a torque of

82-90 Nm.

Reinstall and shimming the differential unit

Position the cups (29) on their cones (33). Install the shims (22)

recovered at disassembly up against the washer (21). Place the ring gear

assembly in the housing (7). Check that the locating rings (44) are

present. Position the half-bearings (43). Moderately tighten the screws

(42) so that the cups (29) fit freely with no play. Install the unit

horizontally in a vice with soft jaws, with the ring gear facing

upwards.

Shimming - Before shimming the differential unit, check that the ring

gear is not constrained on the pinion. Position a dial gauge. Tighten

the nut (32) and turn the ring gear (27) several turns to correctly seat

the cones in the cups. Retighten the nut to eliminate the axial

clearance. After eliminating the axial clearance, tighten the nut (32)

three more notches to obtain the correct preload.

Checking the backlash

Check the backlash using a dial gauge, moving it both ways around the

ring gear without causing the pinion to turn. Take three readings at

three equidistant points. Calculate the average of the three readings to

obtain a backlash between 0.18 and 0.23 mm. If the value measured is too

high, reduce the thickness of the shims (22), and if it is too low,

increase the thickness of the shims to obtain the correct backlash.

Repeat the differential unit shimming operation. Remove the screws (42)

one by one from the bearings, smear with Loctite 270 and tighten to a

torque of 115-127 Nm. Reassemble the lock (31) with the screw (30)

smeared with Loctite 270 and tighten to a torque of 16-25 Nm. Lock the

nut (32) by folding the lock tab into the corresponding spline.

Piston tightness test

On the differential lock supply union, Install a pressure gauge fitted

with a valve whose tightness has been checked beforehand. Supply the

system with compressed air at a pressure of approximately 5 bar and

check the reaction of the piston (14). Lower the pressure to 0.3 bar and

close the valve. No drop in pressure should be recorded on the pressure

gauge for approximately one minute. Remove the pressure gauge and valve

assembly.

Massey Ferguson 5445, 5455, 5460, 6460, 6470 - Reinstall

the drive pinion carrier

Check and clean the components. Replace any defective parts. Check for

the presence of the rings on the axle housing. Smear the mating face of

the differential housing on the axle housing with a sealing product,

Loctite 510 or equivalent, and tighten two diametrically opposed guide

studs. Reinstall the drive pinion carrier. Take out the guide studs.

Install and tighten the screws to a torque of 125-140 Nm. Reinstall the

steering ram. Smear the screws with Loctite 270 and tighten them to

180-200 Nm. Reinstall swivel housings, wheel hubs and transmissions -

Using a suitable sling, support and then refit the complete right and

left-hand swivel housing assemblies.

Assembling the front axle and frame

Connect the axle and its bearings to the front frame. Top up the oil

level in the front axle housing and check the oil level in the final

drives. Carry out a road test for the front axle and differential lock

control. Check tightness: of the seals and the differential housing

mating face, hydraulic unions.

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF FRONT END LOADERS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS MAINTENANCE |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS TROUBLESHOOTING | ||||

| 1652 | 1749 | 2620 | 2725 | 2805 |

| 3050 | 3120 | 3640 | 3709 | 4245 |

| 4455 | 5320 | 5455 | 5613 | 6150 |

| 6280 | 6480 | 6615 | 7618 | 7720 |

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS 130

130 133

133 145

145 155

155 158

158 165

165 175

175 185

185 188

188 230

230 254

254 254S

254S 284S

284S 294

294 353

353 290

290 362

362 375

375 390

390 398

398 399

399 590

590 690

690 1010

1010 1030

1030 1020

1020 1150

1150 2620

2620 2640

2640 2645

2645 1540

1540 2660

2660 3065

3065 3095

3095 3650

3650 3680

3680 4255

4255 4355

4355 4370

4370 3630

3630 3635

3635 4245

4245 4445

4445 4609

4609 4710

4710 5435

5435 5475

5475 5610

5610 5711

5711 6150

6150 6170

6170 6180

6180 6270

6270 6290

6290 6445

6445 6499

6499 6614

6614 6713

6713 7465

7465 7495

7495 7614

7614 7622

7622 7715

7715 7726

7726 8210

8210 8270

8270 8650

8650 8727

8727 GC1705

GC1705 1464 Loader

1464 Loader 1466 Loader

1466 Loader 1040 Loader

1040 Loader 1070 Loader

1070 Loader 905 Loader

905 Loader 906 Loader

906 Loader 915 Loader

915 Loader 916 Loader

916 Loader 921 Loader

921 Loader 926 Loader

926 Loader 931 Loader

931 Loader 933 Loader

933 Loader 936 Loader

936 Loader 938 Loader

938 Loader 939 Loader

939 Loader 940 Loader

940 Loader 941 Loader

941 Loader 945 Loader

945 Loader 946 Loader

946 Loader 948 Loader

948 Loader 949 Loader

949 Loader 950 Loader

950 Loader 951 Loader

951 Loader 955 Loader

955 Loader 956 Loader

956 Loader 958 Loader

958 Loader 960 Loader

960 Loader 961 Loader

961 Loader 965 Loader

965 Loader 966 Loader

966 Loader 968 Loader

968 Loader 975 Loader

975 Loader 976 Loader

976 Loader 978 Loader

978 Loader 985 Loader

985 Loader FL.3114 X

FL.3114 X FL.3419 X

FL.3419 X FL.3522

FL.3522 FL.3615

FL.3615 FL.3619

FL.3619 FL.3817

FL.3817 FL.3819

FL.3819 FL.3823

FL.3823 FL.4018

FL.4018 FL.4121

FL.4121 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader FL.4125

FL.4125 FL.4227

FL.4227 FL.4124

FL.4124 FL.4220

FL.4220 FL.4323

FL.4323 FL.4327

FL.4327 FL.4621

FL.4621 FL.4624

FL.4624 FL.4628

FL.4628 FL.5033

FL.5033 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader 1010

1010 1020

1020 1030

1030 1035

1035 1040

1040 1045

1045 1080

1080 1085

1085 1120

1120 1125

1125 1140

1140 1160

1160 1165

1165 1180

1180 1190

1190 1205

1205 1210

1210 1215

1215 1220

1220 1225

1225 1230

1230 1233

1233 1235

1235 1240

1240 1260

1260