________________________________________________________________________________

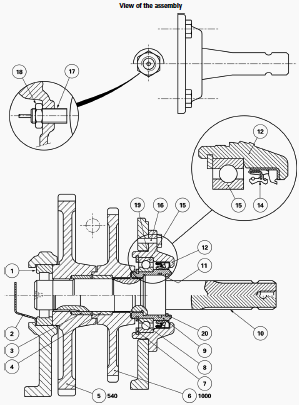

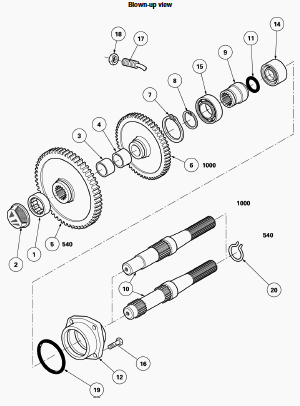

Massey Ferguson 5445, 5465, 5470 PTO - Removable shaft

The driven gears (5) (6) are fitted on the PTO shaft located on the lower part of the axle housing. These gears are constantly meshed with the double driving gear driven by the upper shaftline whose speed is transmitted by the PTO clutch. The PTO shaft (10) is fitted at the front on a bearing (1) force-fitted in the axle housing, and at the rear on a hub (9) rotating on a bearing (15).

The 540 rpm version has 6 splines, and the 1000 rpm version has 21

splines. In the 540 rpm configuration, the shaft (10) is splined to the

gear (5). The gear (6) and ring (4) assembly rotate idle on the shaft

(10). In the 1000 rpm configuration, the shaft is splined to the gear

(6). The gear (5) and ring (3) assembly rotate idle on the shaft (10).

The snap ring (20) holds the shaft in place. Sealing is provided by the

ring (14) and the "O" rings (11) (19).

Parts list - (1) Bearing (2) Deflector (3) Ring (4)

Ring (5) Gear (540 rpm) (6) Gear (1000 rpm) (7) Circlip (8) Snap ring

(9) Hub (10) 540 or 1000 rpm PTO shaft (11) "O" ring (12) Unit (14) Seal

ring (15) Bearing (16) Screw (17) PTO speed sensor (18) Nut (19) "O"

ring (20) Snap ring

MF 5435, 5445, 5455, 5460, 5465, 5470, 5475

PTO - Replacing the 540 or 1000 rpm shaft

Disassembly

Raise the rear of the tractor to avoid oil drainage. Remove the snap

ring (20). Take out the shaft (10). Remove the "O" ring (11) and discard

it.

Reassembly

Fit a new "O" ring (11). Clean and refit the shaft (10). Refit the snap

ring (20) and lower the rear of the tractor.

Massey Ferguson 5435, 5445, 5455, 5460, 5465,

5470, 5475 PTO - Removing and refitting the rear bearing

Partially drain the rear axle housing. Remove the two diametrically

opposed screws (16). Screw two guide studs up against the gear (6). The

purpose of this operation is to hold the gears (5) and (6) in line when

removing the shaft (10) and the rear bearing assembly. Remove the other

two screws (16). Remove the shaft and the rear bearing assembly.

Refitting

Fit the shaft and the rear bearing assembly. Smear two screws (16) with

Loctite 542, then tighten to a torque of 105-120 Nm. Remove the two

guide studs. Smear the other two screws (16) with Loctite 542, and then

tighten to a torque of 105-120 Nm. Top up the rear axle housing oil

level.

Disassembling and reassembling the rear

bearing

Remove the rear bearing and perform steps.

Disassembly

Remove the "O" ring (19). Remove the snap ring (20). Separate the shaft

(10) from the bearing assembly. Remove the "O" ring (11). Remove the

circlip (7). Separate the unit (12) from the bearing (15). Remove the

snap ring (8). Extract the bearing (15) from the hub (9). Remove the

seal ring (14).

Reassembly

Smear the external surface of the seal ring (14) with Loctite 542. Using

a press and a suitable fixture, fit the seal ring (14) up against the

shoulder of the unit (12). The double lip must be turned towards the

bearing (15). Assemble the bearing. Perform steps 17 to 24 in reverse

order and refit the bearing.

MF 5435, 5445, 5455, 5460, 5465, 5470, 5475

PTO - Disassembling and reassembling the 540 and 1000 rpm gears and the

front bearing

Disassembly

To remove the gears (5) (6), it is necessary to remove: the linkage

cover plate, the top cover plate at the rear of the PTO shaftline, the

driving gear and the intermediate shaft. To gain access to the sensor,

remove the left-hand ram by removing the lower attachment and by

disconnecting the supply hose. Remove the PTO sensor. Remove the rear

bearing and perform steps. Remove the gears (5) (6). Extract the bearing

(1) and the deflector (2).

Reassembly

Check and clean the components. Replace any defective parts. Smear the

deflector (2) with Loctite 648 on its mating face with the housing and

fit it into its bore. Turn the opening upwards. Fit the bearing (1) in

the housing, up against the deflector (2). Lubricate the rings (3) (4).

Refit the gears (5) (6) and screw two guide studs up against the gear

(6). The purpose of this operation is to hold the gears in line while

refitting the rear bearing. If the rings (3) (4) are damaged, replace

the gears (5) (6). Refit the rear bearing.

Smear the thread of the PTO sensor with Loctite "Form A gasket 2" (sensor sealing or equivalent). Adjust the sensor: Screw the sensor in fully, without forcing, until it comes in contact with the gear (6). Unscrew the sensor by 3/4 of a turn. Tighten the nut (18) moderately and connect the harness. Refit the left-hand ram, refit the lower attachment and reconnect the supply hose. Refit the driving gear assembly. Refit the linkage cover plate. Top up the rear axle oil level. Check PTO and PTO brake operation. Check tightness: of the mating faces (spool valve support, linkage cover plate, cover plate, PTO rear bearing).

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF FRONT END LOADERS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS MAINTENANCE |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS TROUBLESHOOTING | ||||

| 1652 | 1749 | 2620 | 2725 | 2805 |

| 3050 | 3120 | 3640 | 3709 | 4245 |

| 4455 | 5320 | 5455 | 5613 | 6150 |

| 6280 | 6480 | 6615 | 7618 | 7720 |

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS 130

130 133

133 145

145 155

155 158

158 165

165 175

175 185

185 188

188 230

230 254

254 254S

254S 284S

284S 294

294 353

353 290

290 362

362 375

375 390

390 398

398 399

399 590

590 690

690 1010

1010 1030

1030 1020

1020 1150

1150 2620

2620 2640

2640 2645

2645 1540

1540 2660

2660 3065

3065 3095

3095 3650

3650 3680

3680 4255

4255 4355

4355 4370

4370 3630

3630 3635

3635 4245

4245 4445

4445 4609

4609 4710

4710 5435

5435 5475

5475 5610

5610 5711

5711 6150

6150 6170

6170 6180

6180 6270

6270 6290

6290 6445

6445 6499

6499 6614

6614 6713

6713 7465

7465 7495

7495 7614

7614 7622

7622 7715

7715 7726

7726 8210

8210 8270

8270 8650

8650 8727

8727 GC1705

GC1705 1464 Loader

1464 Loader 1466 Loader

1466 Loader 1040 Loader

1040 Loader 1070 Loader

1070 Loader 905 Loader

905 Loader 906 Loader

906 Loader 915 Loader

915 Loader 916 Loader

916 Loader 921 Loader

921 Loader 926 Loader

926 Loader 931 Loader

931 Loader 933 Loader

933 Loader 936 Loader

936 Loader 938 Loader

938 Loader 939 Loader

939 Loader 940 Loader

940 Loader 941 Loader

941 Loader 945 Loader

945 Loader 946 Loader

946 Loader 948 Loader

948 Loader 949 Loader

949 Loader 950 Loader

950 Loader 951 Loader

951 Loader 955 Loader

955 Loader 956 Loader

956 Loader 958 Loader

958 Loader 960 Loader

960 Loader 961 Loader

961 Loader 965 Loader

965 Loader 966 Loader

966 Loader 968 Loader

968 Loader 975 Loader

975 Loader 976 Loader

976 Loader 978 Loader

978 Loader 985 Loader

985 Loader FL.3114 X

FL.3114 X FL.3419 X

FL.3419 X FL.3522

FL.3522 FL.3615

FL.3615 FL.3619

FL.3619 FL.3817

FL.3817 FL.3819

FL.3819 FL.3823

FL.3823 FL.4018

FL.4018 FL.4121

FL.4121 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader FL.4125

FL.4125 FL.4227

FL.4227 FL.4124

FL.4124 FL.4220

FL.4220 FL.4323

FL.4323 FL.4327

FL.4327 FL.4621

FL.4621 FL.4624

FL.4624 FL.4628

FL.4628 FL.5033

FL.5033 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader 1010

1010 1020

1020 1030

1030 1035

1035 1040

1040 1045

1045 1080

1080 1085

1085 1120

1120 1125

1125 1140

1140 1160

1160 1165

1165 1180

1180 1190

1190 1205

1205 1210

1210 1215

1215 1220

1220 1225

1225 1230

1230 1233

1233 1235

1235 1240

1240 1260

1260