________________________________________________________________________________

Massey Ferguson 5455, 5460, 5465 - Brake piston

On MF 5435, 5445, 5455, 5460, 5465, 5470, 5475 tractors the brake pistons are housed in two lateral cavities of the rear axle housing, concentric with the mating face of each trumpet housing. They comprise a shouldered part and are guided by 3 centring pins force-fitted in the housing. Sealing is provided by two "O" rings fitted in the grooves of the rear axle housing. Each piston is controlled by a master cylinder topped by a tank whose level is kept constant by the residual oil flow from the 17 bar valve. Each piston acts directly on a friction disc with inserted hub, fitted to the trumpet housing input sun gear and a plate centred by pins bearing on the final drive ring gear.

When the brake is released, a self-adjusting mechanism ensures minimum

clearance between the piston and the brake disc and maintains a constant

pedal clearance. The brake discs are lubricated by a flow of oil. This

continuous flow from the linkage valve is directed to the brake discs

via a pipe and a restrictor union screwed onto the trumpet housing. The

oil circulating between the discs and the pistons lubricates the braking

surfaces when they are not in use and cools the brakes when they are

being used.

Massey Ferguson 5435, 5445, 5455, 5460, 5465,

5470, 5475 - Disassembly and reassembly brake piston

Brake piston disassembly

Remove the trumpet housing.

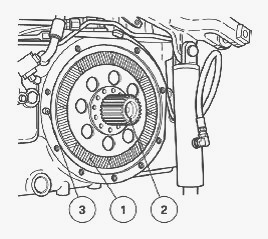

Remove the disc (1), the sun gear (2), and the centring pin (3). Remove

the brake plate (1) (inside the trumpet housing). Remove the screws (3)

using a makeshift socket.

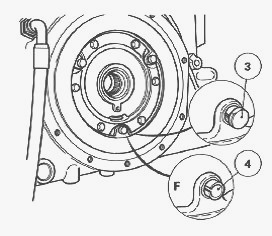

Take the piston (1) out of the housing using a jet of compressed air

applied to the union (2). To facilitate access to the union (2), if

necessary, disconnect the 4-speed economy PTO control (if fitted) and

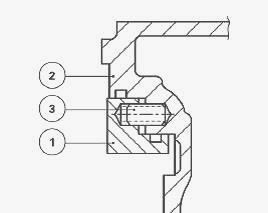

turn the union. Remove the "O" rings (1) and (2) on the housing and

discard them.

Brake piston reassembly

Check and clean the components. Replace any defective parts. To ensure

that the brake self-adjusting system operates correctly, it is essential

to centre the right and left-hand differential flanges using a makeshift

tool.

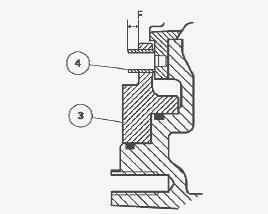

Install the piston (1) without seals in the housing (2) and check that

the piston slides freely in the bore of the housing and that it fits

smoothly onto the centring pins (3). Remove the piston after carrying

out this check. Install spring pins (4) about 8 mm from machined face

"F" of the piston (3). Install the new "O" rings (1) and (2) after

smearing them with a moderate quantity of miscible grease so that they

remain at the bottom of the groove.

Position the piston over the centring pins, then Install the piston in

place using a plastic hammer, striking alternate points around the rim.

Install the screws (3) after lightly smearing them with Loctite 241 and

tighten them to a torque of 10 Nm with a makeshift socket.

Massey Ferguson 5435, 5445, 5455, 5460, 5465,

5470, 5475 - brake piston sealing test

If work is carried out on the brake piston and "O" rings, it is

necessary to check for leaks. Check the condition of the supply union

fitted on the centre housing. Install a pressure gauge to the union.

Supply the system with compressed air at approx. 5 bar to ensure that

the piston and "O" rings are positioned correctly. Reduce the pressure

to 0.3 bar to carry out the test. Close off the pressure relief valve.

For one minute, no drop in pressure should be observed on the pressure

gauge. Remove the pressure gauge and reconnect the brake hose.

Reinstall the trumpet housing

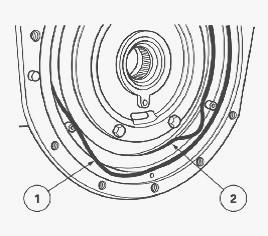

Clean the mating faces on the housing and on the trumpet housing with a

non-greasy solvent. Apply a bead of silicon resistant to hydrocarbons

(Silicomet type) to the inside edge of the housing. Re Install the sun

gear (2), the disc (1), and the centring pin (3). Check that the disc

slides freely on the sun gear. Reinstall the trumpet housing. Bleed the

main brake system and trailer brake system (if fitted). Test: the

linkage, the braking by carrying out a road test. Check tightness:

between the trumpet housing and the rear axle housing, of the linkage

valve supply hose.

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF FRONT END LOADERS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS MAINTENANCE |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS TROUBLESHOOTING | ||||

| 1652 | 1749 | 2620 | 2725 | 2805 |

| 3050 | 3120 | 3640 | 3709 | 4245 |

| 4455 | 5320 | 5455 | 5613 | 6150 |

| 6280 | 6480 | 6615 | 7618 | 7720 |

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS 130

130 133

133 145

145 155

155 158

158 165

165 175

175 185

185 188

188 230

230 254

254 254S

254S 284S

284S 294

294 353

353 290

290 362

362 375

375 390

390 398

398 399

399 590

590 690

690 1010

1010 1030

1030 1020

1020 1150

1150 2620

2620 2640

2640 2645

2645 1540

1540 2660

2660 3065

3065 3095

3095 3650

3650 3680

3680 4255

4255 4355

4355 4370

4370 3630

3630 3635

3635 4245

4245 4445

4445 4609

4609 4710

4710 5435

5435 5475

5475 5610

5610 5711

5711 6150

6150 6170

6170 6180

6180 6270

6270 6290

6290 6445

6445 6499

6499 6614

6614 6713

6713 7465

7465 7495

7495 7614

7614 7622

7622 7715

7715 7726

7726 8210

8210 8270

8270 8650

8650 8727

8727 GC1705

GC1705 1464 Loader

1464 Loader 1466 Loader

1466 Loader 1040 Loader

1040 Loader 1070 Loader

1070 Loader 905 Loader

905 Loader 906 Loader

906 Loader 915 Loader

915 Loader 916 Loader

916 Loader 921 Loader

921 Loader 926 Loader

926 Loader 931 Loader

931 Loader 933 Loader

933 Loader 936 Loader

936 Loader 938 Loader

938 Loader 939 Loader

939 Loader 940 Loader

940 Loader 941 Loader

941 Loader 945 Loader

945 Loader 946 Loader

946 Loader 948 Loader

948 Loader 949 Loader

949 Loader 950 Loader

950 Loader 951 Loader

951 Loader 955 Loader

955 Loader 956 Loader

956 Loader 958 Loader

958 Loader 960 Loader

960 Loader 961 Loader

961 Loader 965 Loader

965 Loader 966 Loader

966 Loader 968 Loader

968 Loader 975 Loader

975 Loader 976 Loader

976 Loader 978 Loader

978 Loader 985 Loader

985 Loader FL.3114 X

FL.3114 X FL.3419 X

FL.3419 X FL.3522

FL.3522 FL.3615

FL.3615 FL.3619

FL.3619 FL.3817

FL.3817 FL.3819

FL.3819 FL.3823

FL.3823 FL.4018

FL.4018 FL.4121

FL.4121 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader FL.4125

FL.4125 FL.4227

FL.4227 FL.4124

FL.4124 FL.4220

FL.4220 FL.4323

FL.4323 FL.4327

FL.4327 FL.4621

FL.4621 FL.4624

FL.4624 FL.4628

FL.4628 FL.5033

FL.5033 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader 1010

1010 1020

1020 1030

1030 1035

1035 1040

1040 1045

1045 1080

1080 1085

1085 1120

1120 1125

1125 1140

1140 1160

1160 1165

1165 1180

1180 1190

1190 1205

1205 1210

1210 1215

1215 1220

1220 1225

1225 1230

1230 1233

1233 1235

1235 1240

1240 1260

1260