________________________________________________________________________________

Massey Ferguson 5465, 5470, 5475 - Hand brake unit and control

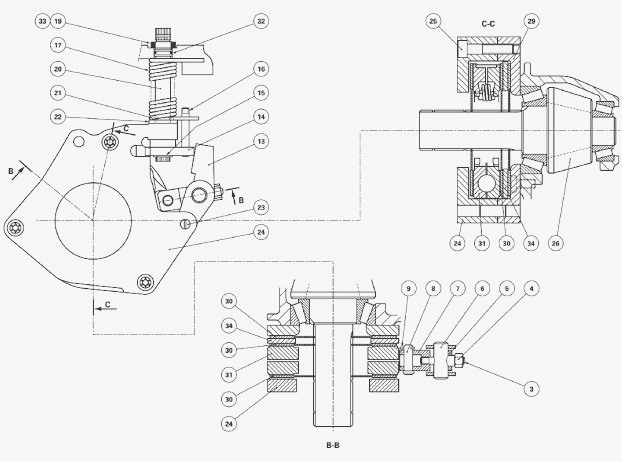

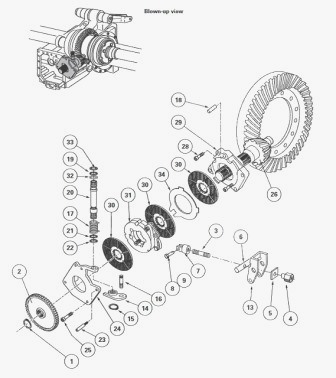

The hand brake assembly is fitted on the pinion. It consists of a

mechanism placed between three friction discs splined to the pinion. The

mechanism comprises two cast iron plates held by springs and separated

by ball bearings housed in rails. The three discs are fitted to the

pinion as follows: two discs separated by an intermediate plate between

the thrust plate (29) and the mechanism, disc between the mechanism and

the cover plate (24).

Hand brake operation

When the hand brake lever in the cab is pulled, the cam (14) is moved

via the pin (20). The cam pushes the rod (13) which causes the plates of

the mechanism (31) to rotate and move apart. The discs (30) are then

compressed between the moving plates (31), the intermediate plate (34),

the cover plate (24) and the thrust plate (29), preventing the pinion

from rotating. When the hand brake lever is released, the spring (17)

brings the cam (14) back to the rest position and the mechanism is

returned by its springs.

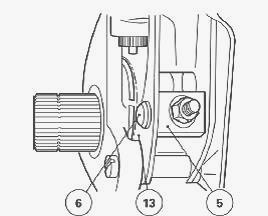

Parts list - (1) Circlip (2) Gear (3) Stud (4) Nut (5)

Gear plate (6) Pin (7) Clevis (8) Pin (9) Pin (10) Left-hand cover plate

(11) Plug (12) Seal (13) Rod (14) Cam (15) Circlip (16) Finger (17)

Spring (18) Centring pin (19) Seal (20) Control pin (21) Snap ring (22)

Washer (23) Finger (24) Cover plate (25) Screw (26) Pinion (27) Shim(s)

(28) Screw (29) Thrust plate (30) Discs (31) Mechanism (32) "O" ring

(33) Retaining ring (34) Intermediate plate

Massey Ferguson 5435, 5445, 5455, 5460, 5465,

5470, 5475 - Hand brake disassembly

Drain the rear axle housing. Chock: the front wheels of the tractor,

between the frame and the front axle. Raise the MF 5435, 5445, 5455,

5460, 5465, 5470, 5475 tractor using a jack. Place axle stands in

position. Remove the rear wheels. Remove the right and left-hand

hydraulic cover plates.

MF 5435, 5445, 5455, 5460, 5465, 5470, 5475 Tractor with no

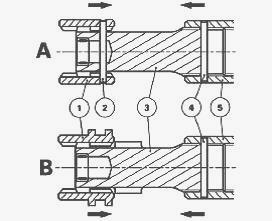

creeper unit A

Drive out the double pins (2) (4) from the coupling sleeves (1) (5).

Slide the sleeves towards each other on the shaft (3) linking the pinion

(26) and the gearbox output shaft. Remove the shaft and sleeve assembly.

On MF 5435, 5445, 5455, 5460, 5465, 5470, 5475 4WD tractors: If the pins

are not accessible, disconnect the front axle shaft by sliding the rear

sleeve and manually turning the front axle clutch shaft to position the

shaft (3). Remove the circlip (1). Remove the gear (2) (if fitted).

MF 5435, 5445, 5455, 5460, 5465, 5470, 5475 Tractor with creeper

unit B

Remove the creeper gear fork and the sleeve assembly (connecting shaft

and coupler).

MF 5435, 5445, 5455, 5460, 5465, 5470, 5475 Tractors with or

without creeper unit

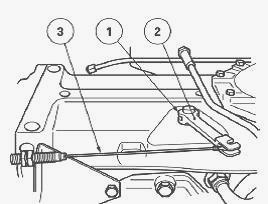

If necessary, remove the cab screws. Raise and chock the cab. Check the

space between the bonnet and the windscreen (if the space is too narrow,

remove the body). Disconnect the cable (3). Take out the pin (1) and

remove the control rod (2).

Remove the retaining ring (33) and remove the seal (19). Release the

spring (17) using a pair of pliers. Loosen the nut (4) to release the

rod (13) from the cam (14). Remove the circlip (15). Remove the cam (14)

with the finger (16). Remove the screw (25). Remove the cover plate (24)

and the control pin (20). Keep the mechanism (31) and the brake discs

(30) towards the rear. Extract the cover plate (24), tilting it to

disengage it from the pin (18), the finger (23) and the pinion (26) and

to release the pin (20) from the housing. Remove the spring (17) and the

washer (22). Remove the snap ring (21) (if necessary) on the control pin

(20). Remove the discs (30) and the mechanism (31).

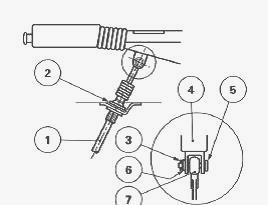

If replacing the mechanism - Unscrew the nut (4) and remove the plate

(5) and the pin (6). Take out the pin (9) and remove the pin (8) and the

clevis (7). The stud (3) is smeared with Loctite 270 and locked in the

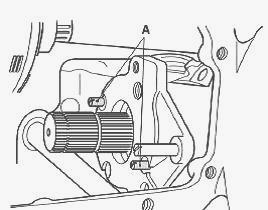

clevis (7). If replacing the thrust plate (29) - Remove two

diametrically opposed screws (28) and screw in two guide studs (A). The

purpose of this operation is to hold the shims (27).

Unscrew the two remaining screws. Remove the thrust plate (29). Check

that the shims have all remained on the housing. The finger (16) smeared

with Loctite 270 is screwed onto the cam (14). The finger (23) smeared

with Loctite 270 is screwed onto the thrust plate. The centring pin (18)

is fitted home on the shoulder of the cover plate (24). Check and clean

the components. Replace any defective parts.

If replacing the thrust plate (29) - Reinstall the plate. Smear the two

screws (28) with Loctite 270 and then tighten them to a torque of 90-120

Nm. If replacing the mechanism - Reinstall the clevis (7) prepared with

the stud (3) and the pin (8). Reinstall the pin (9). Install the rod

(13) with its pin (6) on the stud (3) of the clevis. Reinstall the plate

(5) and screw on the nut (4). The plate (5) is rectangular. It must be

positioned horizontally so that the pin (6) Install correctly on the rod

(13).

Reinstall the discs (30), placing the mechanism (31) between them.

Insert the rod (13) on the finger (23). Check that the discs slide

freely on the shaft of the pinion (26). Install the snap ring (21) (if

removed) on the pin (20). Install the pin (20) in the cover plate (24)

with the washer (22), the spring (17) and the seal (32). Check that the

discs (30) and the mechanism (31) are correctly positioned. Install and

tighten the screws (25) to a torque of 90 - 120 Nm. Install the cam (14)

with its finger (16).

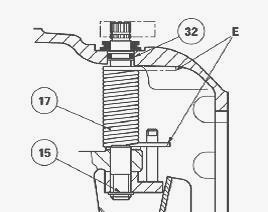

Position the circlip (15). Re-tension the spring (17), while positioning

its ends E as indicated. Lightly smear the pin (20) with AS 767

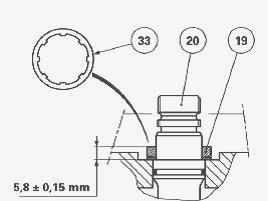

Anti-Seize grease or equivalent. Install the seal (19) on the housing

and compress it to 5.8 ± -0.15 mm using a retaining ring (33).

Reinstall the gear (2) (if fitted). Position the circlip (1). Depending

on the model: 1) with creeper unit - refit the sleeve assembly

(connecting shaft and coupler) and the creeper gear fork. Turn the

groove on the pinion sleeve towards the rear of the tractor. Replace the

pins. Adjust the forks. 2) without creeper unit - refit the sleeve

assembly (connecting shaft and coupler). Turn the groove on the pinion

sleeve towards the rear of the tractor. Replace the pins. Reinstall the

left-hand cover plate.

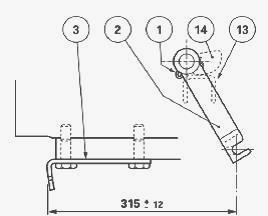

Position the rod (2) with the cam (14) in contact with the rod (13) to

obtain a distance of 315 mm ± 12 mm between the cable attachment axis

and the support (3). Install the pin (1).

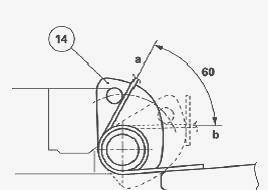

Adjust the mechanism (31) with the adjustment nut, so that the cam

displacement from rest position "a" to maximum position "b" is 60°. The

adjustment nut (4) is accessed via the plug port (3) on the left-hand

cover plate. Reconnect the control. Adjust the hand brake control

reverse. Reinstall the right-hand hydraulic cover plate. Raise the

tractor using a jack. Install the wheels.

Remove the axle stands and the jack. Tighten the wheels to a torque of

400-450 Nm. Remove the chocks at the front of the tractor between the

frame and the front axle. Top up the rear axle housing oil level. Check

the operation of the electrical circuits, the low pressure switch, the

solenoid valves and the blockage indicator. Check the operation of the

linkage and the hand brake. Check the tightness of the mating faces,

cover plates and hydraulic unions.

Massey Ferguson 5435, 5445, 5455, 5460, 5465,

5470, 5475 - Assembling and adjusting the hand brake control

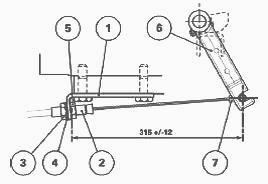

Introduce the cable (1) from below towards the cab interior and fasten

with the clip (2). Fix the clevis (7) on the brake lever (4) with the

pin (5), the washer (6) and the pin (3). Check that the cable is not

pinched. Install the sheath end (2) in the attachment support (1).

Attach the end of the cable (7) to the lever (6). Place the hand brake

lever in the released position. Make essential adjustments to obtain a

distance of 315 mm ± 12 mm between the nut (5) and the centreline of the

cable end (7). Tighten the nut (3) on the washer (4).

Check the operation of the control. Tighten the lever. Initial brake

travel should be approximately 8 notches. The indicator light on the

instrument panel should come on and the buzzer should sound if a gear is

engaged. Release the lever. The control should return freely to the rest

position. In this position, the buzzer stops and the indicator light on

the instrument panel should go out.

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF FRONT END LOADERS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS MAINTENANCE |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS TROUBLESHOOTING | ||||

| 1652 | 1749 | 2620 | 2725 | 2805 |

| 3050 | 3120 | 3640 | 3709 | 4245 |

| 4455 | 5320 | 5455 | 5613 | 6150 |

| 6280 | 6480 | 6615 | 7618 | 7720 |

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS 130

130 133

133 145

145 155

155 158

158 165

165 175

175 185

185 188

188 230

230 254

254 254S

254S 284S

284S 294

294 353

353 290

290 362

362 375

375 390

390 398

398 399

399 590

590 690

690 1010

1010 1030

1030 1020

1020 1150

1150 2620

2620 2640

2640 2645

2645 1540

1540 2660

2660 3065

3065 3095

3095 3650

3650 3680

3680 4255

4255 4355

4355 4370

4370 3630

3630 3635

3635 4245

4245 4445

4445 4609

4609 4710

4710 5435

5435 5475

5475 5610

5610 5711

5711 6150

6150 6170

6170 6180

6180 6270

6270 6290

6290 6445

6445 6499

6499 6614

6614 6713

6713 7465

7465 7495

7495 7614

7614 7622

7622 7715

7715 7726

7726 8210

8210 8270

8270 8650

8650 8727

8727 GC1705

GC1705 1464 Loader

1464 Loader 1466 Loader

1466 Loader 1040 Loader

1040 Loader 1070 Loader

1070 Loader 905 Loader

905 Loader 906 Loader

906 Loader 915 Loader

915 Loader 916 Loader

916 Loader 921 Loader

921 Loader 926 Loader

926 Loader 931 Loader

931 Loader 933 Loader

933 Loader 936 Loader

936 Loader 938 Loader

938 Loader 939 Loader

939 Loader 940 Loader

940 Loader 941 Loader

941 Loader 945 Loader

945 Loader 946 Loader

946 Loader 948 Loader

948 Loader 949 Loader

949 Loader 950 Loader

950 Loader 951 Loader

951 Loader 955 Loader

955 Loader 956 Loader

956 Loader 958 Loader

958 Loader 960 Loader

960 Loader 961 Loader

961 Loader 965 Loader

965 Loader 966 Loader

966 Loader 968 Loader

968 Loader 975 Loader

975 Loader 976 Loader

976 Loader 978 Loader

978 Loader 985 Loader

985 Loader FL.3114 X

FL.3114 X FL.3419 X

FL.3419 X FL.3522

FL.3522 FL.3615

FL.3615 FL.3619

FL.3619 FL.3817

FL.3817 FL.3819

FL.3819 FL.3823

FL.3823 FL.4018

FL.4018 FL.4121

FL.4121 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader FL.4125

FL.4125 FL.4227

FL.4227 FL.4124

FL.4124 FL.4220

FL.4220 FL.4323

FL.4323 FL.4327

FL.4327 FL.4621

FL.4621 FL.4624

FL.4624 FL.4628

FL.4628 FL.5033

FL.5033 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader 1010

1010 1020

1020 1030

1030 1035

1035 1040

1040 1045

1045 1080

1080 1085

1085 1120

1120 1125

1125 1140

1140 1160

1160 1165

1165 1180

1180 1190

1190 1205

1205 1210

1210 1215

1215 1220

1220 1225

1225 1230

1230 1233

1233 1235

1235 1240

1240 1260

1260