________________________________________________________________________________

Massey Ferguson 6465, 6475, 6480 - Ground Speed PTO

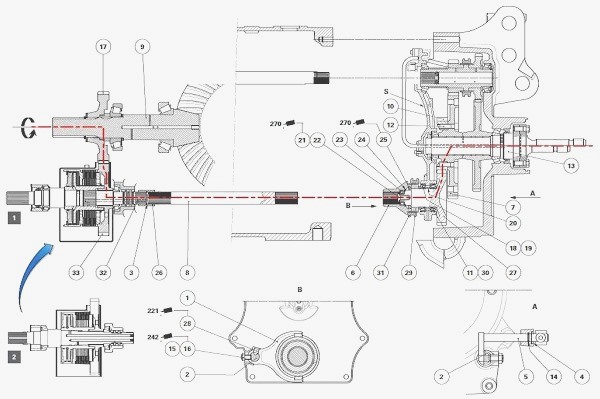

Ground speed power take-off may be available (depending on option) on MF

6465, 6475, 6480 tractors. In contrast to the independent PTO mechanism

where the speed of the rear PTO output shaft depends on the speed of the

engine, Ground Speed PTO is driven by the pinion and a set of gears also

used by the 4WD clutch unit. The speed of the rear PTO output shaft is

therefore proportional to the tractor's travel speed.

Massey Ferguson 6465, 6475, 6480 Ground Speed

PTO - Construction and Operation

Construction

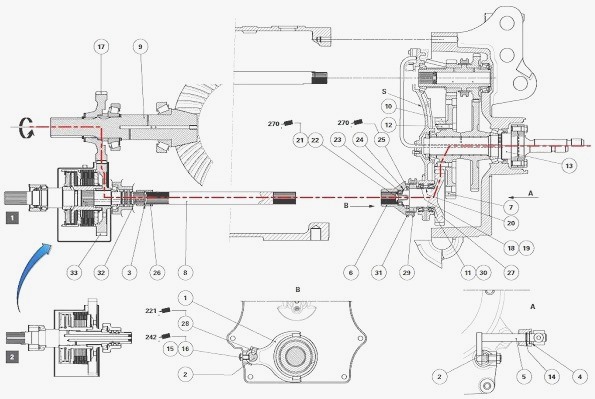

The pinion of the rear crownwheel and pinion supports the driving gear

(17), which is constantly meshed with the bell gear (33) of the 4WD

clutch unit. On the ground speed PTO, the gear (27) is constantly meshed

with the driven gear (10), which is attached to the 540 rpm driven gear

(7) by the screw (12). This gear is itself splined to the output shaft

(13) of the rear PTO.

Operation

The forward movement of the coupler (31) allows the movement transmitted

by the gears (17) (33) to travel towards the output shaft (13) of the

rear PTO via the shaft (8) and the gears (27) (10). The coupling is

activated by an external rod located at the bottom right of the rear PTO

housing. This rod is connected to a cable, which is connected to a

control lever accessible from the cab. A switch connected to this

control lever electronically controls the engagement of the ground speed

PTO. When the Ground speed power take-off is engaged, the independent

540 - 1000 rpm PTO is deactivated.

Parts list: (1) Fork (2) Selector rail (3) Circlip (4)

Snap ring (5) Control pin/finger (6) Splined sleeve (7) 540 rpm driven

gear (8) Shaft (9) Pinion (10) Driven gear (11) Bearing cone (12) Screw

(13) Output shaft (14) "O" ring (15) Pushrod screw (16) Nut (17) Driving

gear (4WD) (18) Bearing cone (19) Bearing cup (20) Shim(s) (21)

Countersunk screw (22) Chamfered washer (23) Ball bearing (24) Circlip

(25) Nut (26) Sleeve (27) Driving gear/shaft assembly (28) Set screw

(29) Hub (30) Bearing cup (31) Coupler (32) 4WD shaft (33) Bell gear

(4WD), A - Details, B - Details, S - Removable support

Massey Ferguson 6465, 6475, 6480 Ground Speed

PTO - Removing and install the selection mechanism and adjusting the

pushrod screw

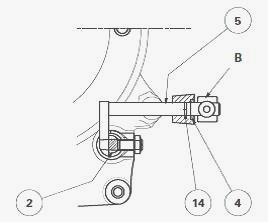

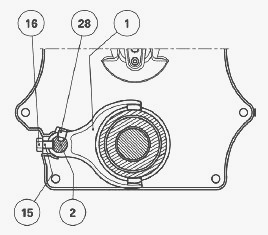

Removing the selection mechanism

Disconnect the PTO housing from the centre housing. Remove rod B. Remove

the snap ring (4). Separate the control pin/finger (5) from the selector

rail (2). Turn it approx. 90° and pull it out of the PTO housing in

order to remove the "O" ring (14). Remove the control pin/finger (5) by

pushing it along its entire length towards the inside of the PTO

housing. Unscrew the nut (16) and the pushrod screw (15) on the selector

rail (2). Unscrew the set screw (28). Remove the selector rail (2) and

the fork (1).

Install the selection mechanism

Clean and check all components. Replace those that are defective.

Install the fork and the selector rail. Lightly smear the thread of the

set screw (28) with Loctite 221 or equivalent. Tighten this screw to a

torque of 25-35 Nm. From the inside of the PTO housing, Install the

control pin/finger (5) in its position and press it fully back towards

the outside of the housing. Lubricate a new "O" ring (14). From the

outside of the PTO housing, Install the new "O" ring (14) in the groove

of the protruding section of the control pin/finger. Push the control

pin/finger assembly back inside the PTO housing. Position it in the slot

on the selector rail (2). Reinstall: new snap ring (4); control rod B.

Lightly smear the thread of the screw on control rod B with Loctite 221

or equivalent. Tighten this screw to a torque of 25-35 Nm. Check the

movement of rod B.

Adjusting the pushrod screw

Position the selector rail (2) so that its flat section is opposite the

tapped hole of the pushrod screw (15). Tighten the pushrod screw (15)

without forcing it in order to compress the ball, then loosen it by one

quarter turn. Clean the thread of the pushrod screw (15) and the nut

(16). Lightly smear the thread of the nut (16) with Loctite 242 or

equivalent. Tighten this nut to 15-20 Nm while holding the pushrod screw

in place. Check that the fork lock matches. Reconnect the PTO housing to

the centre housing. Start the tractor engine and check the ground speed

PTO operation.

Massey Ferguson 6465, 6475, 6480 Ground Speed

PTO - Disassembly and reassembly the gears

Ground speed power take-off comprises a driving gear train (17) (33) and

a driven gear train (27) (10) located respectively at the front and rear

of the centre housing.

If work is necessary on the driving

gear train (17) (33), proceed as follows:

1) To access the gear (17) - Disconnect the tractor between the gearbox

and the centre housing. Remove the gear (17).

2) To access the gear (33) (MF 6465, 6475) - Remove the 4WD clutch unit.

3) To access the gear (33) (MF 6465, 6480) - Disconnect the tractor

between the gearbox and the centre housing. Remove the 4WD clutch unit.

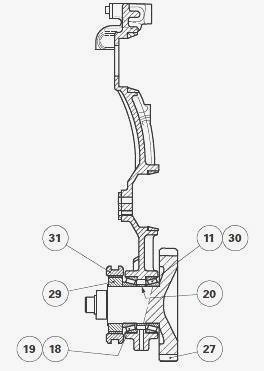

If work is necessary on the driven gear train (27) (10) (all types of

transmission except GTA1540 (50 kph)), remove the rear PTO housing. The

lower bearing and removable support S are also removed with this housing

during the operation.

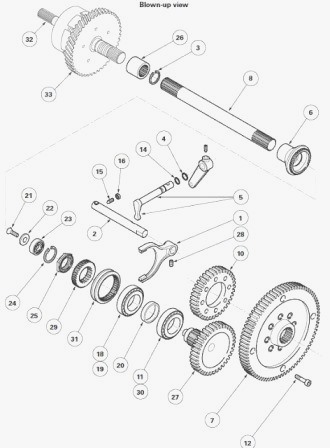

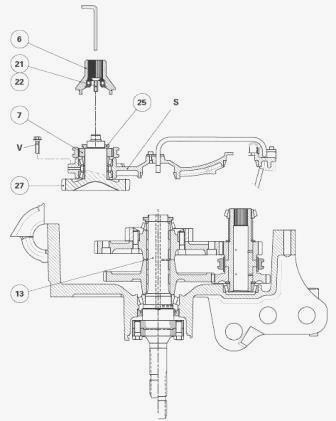

Ground Speed PTO gears disassembly

Disconnect the PTO housing from the centre housing. Place the housing in

a horizontal position with the gears facing upwards as required. Loosen

the nut (16) and the pushrod screw (15) for the 540-1000 rpm selector

rail. Remove the ground speed PTO selection mechanism. Loosen the

countersunk screw (21). Recover the chamfered washer (22).

Remove the splined sleeve (6). Unlock the nut (25). Immobilise the

output shaft using a locally obtained M16 screw. Partially loosen the

nut (25) using a standard socket (55 mm flat). The nut (25) must be

unlocked before removing removable support S in order to take advantage

of the opportunity to lock the output shaft (13) with the M16 screw.

Remove removable support S using bearings at the front ends of the PTO

shafts (upper and lower). Finish unscrewing the nut (25) and remove it.

Also remove: hub (29) and the coupler (31); bearing cone (18) (to be

paired with the cup (19) if it is to be re-used); shims (20); bearing

cone (11) (to be paired with the cup (30) if it is to be re-used);

gear/shaft assembly (27).

Drive out the bearing cups (19) (30) from the removable support. If

necessary, visually note the position of the shaft (8) and remove it

along with the sleeve (26). Remove the circlip (3). The undercut end of

the shaft (8) is positioned towards the 4WD clutch unit. If necessary,

remove the driven gear (10), which is centred and fitted to the 540 rpm

gear (7) via a screw. The method of fitting one gear against another has

already been used in chapter 7 in the section on the GPA40 output shaft

and brake). Strip the sleeve (6) by carrying out the following steps:

Remove the circlip (24). Drive out the ball bearing (23).

Ground Speed PTO gears reassembly

Clean and check all components. Replace those that are defective.

Assemble the sleeve by carrying out the following steps: Install the

ball bearing (23) using a suitable fitting drift whose external diameter

should be slightly less than the external diameter of the ball bearing.

Install the circlip (24). If necessary, reinstall: driven gear (10);

circlip (3) in the sleeve (26); shaft (8). Install the bearing cups (19)

(30) against the removable support cord. Shim the bearings (11) (30) and

(18) (19) of the gear/shaft assembly (27). Install the removable

support. Tighten the V screws to a torque of 68-92 Nm. Clean the threads

of the new nut (25) and the gear pin (27). Lightly smear the nut thread

with Loctite 270 or equivalent. Immobilise the output shaft. Correctly

position the nut. Definitively tighten to 160-240 Nm.

Using a suitable punch, lock the nut in place by bending the collar into

the grooves of the shaft without breaking it. Reinstall the coupler (31)

and the splined sleeve (6). Correctly position the chamfered washer (22)

and install it to the ball bearing (23). Lightly smear the thread of the

countersunk screw (21) with Loctite 270 or equivalent. Tighten this

screw to a torque of 24-28 Nm. Reinstall and adjust the ground speed PTO

selection mechanism. Install the pushrod screw (15) and the nut (16) of

the 540-1000 rpm selector rail. Adjust the pushrod screw. Reconnect the

PTO housing to the centre housing. Start the tractor engine and check

the Ground speed power take-off operation.

Massey Ferguson 6465, 6475, 6480 Ground Speed

PTO - Shimming the gear/shaft assembly bearings

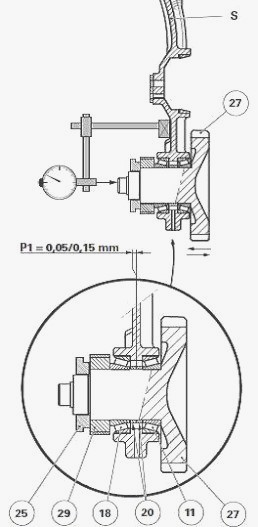

The gear/shaft assembly (27) is shimmed with removable support S. The

removable support must be removed from the rear PTO housing assembly and

clamped in a vice fitted with protective jaws.

Preparing for shimming

Assemble the gear/shaft assembly (27) with the bearing cones (11) (18)

lightly lubricated. Separate the bearing cones by a shim (20) thickness

in order to obtain a temporary clearance of approx. 0.10 to 0.15 mm.

Install the hub (29). Immobilise the gear/shaft assembly (27) using a

makeshift tool. Temporarily tighten the nut (25) to 30 - 50 Nm with no

Loctite on its thread.

Shimming

Place the feeler pin of a dial gauge on the end of the gear/shaft

assembly (27). Using the appropriate levers, apply diametrically opposed

pressure on the gear of the gear/shaft assembly (27) by pulling on this

assembly in order to fit the cone (18) in its bearing cup. With the help

of an operator, set the dial gauge needle to zero. Repeat, pulling on

the hub (29) in order to Install the cone (11) in its bearing cup.

According to the temporary clearance reading measured on the dial gauge,

determine another shim (20) thickness to obtain a preload P1 = 0.05 to

0.15 mm. As far as possible, shim to the maximum tolerance. Loosen and

remove the nut. Remove the hub (29) and the bearing cone (18). Install

the shims between the two bearing cones (11) (18). Reinstall the hub.

Lock the nut (25) again to a torque of 30-50 Nm, with no Loctite on its

thread, in order to manually check the rotation of the gear.

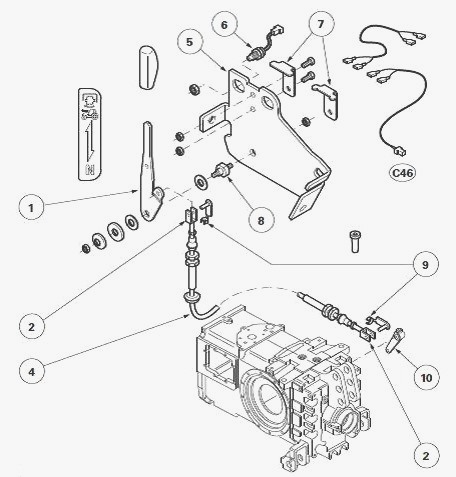

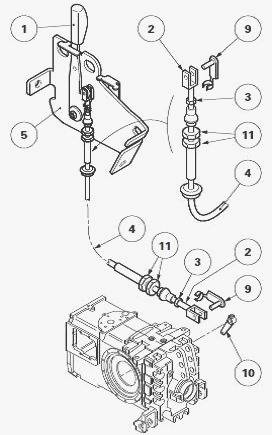

MF 6465, 6475, 6480 Ground Speed PTO -

Assembling and adjusting the control

Parts list: (1) Lever (2) Clevises (4) Cable (5)

Support (6) Switch (7) Stops (8) Pin (9) Clips (10) Connecting rod

Install the control, lever side

Preparing the cable - If possible, tighten the clevis (2) to the maximum

against the cable (4). Tighten the nut (3).

Assembly - Link the clevis to the lever (1) using the clip (9). Tighten

the sheath end to the support (5) using nuts (11).

Install and adjusting the control, centre

housing side

Preparing the cable - If possible, tighten the clevis (2) to the maximum

against the cable (4). Tighten the nut (3).

Assembly - Slide the sheath end of the cable onto the support fitted to

the right of the housing assembly. Place the lever (1) and the rod (10)

in Ground speed power take-off position. Connect the clevis (2) to the

rod (10) using the clip (9).

Settings

Adjust the sheath end on the support using the nuts (11) and without

moving the rod (10). Tighten the nuts. Check that the control moves

freely in each position (neutral and engaged). The coupler has spur cut

teeth: it can only be controlled if the tractor is almost stationary.

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF FRONT END LOADERS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS MAINTENANCE |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS TROUBLESHOOTING | ||||

| 1652 | 1749 | 2620 | 2725 | 2805 |

| 3050 | 3120 | 3640 | 3709 | 4245 |

| 4455 | 5320 | 5455 | 5613 | 6150 |

| 6280 | 6480 | 6615 | 7618 | 7720 |

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS 130

130 133

133 145

145 155

155 158

158 165

165 175

175 185

185 188

188 230

230 254

254 254S

254S 284S

284S 294

294 353

353 290

290 362

362 375

375 390

390 398

398 399

399 590

590 690

690 1010

1010 1030

1030 1020

1020 1150

1150 2620

2620 2640

2640 2645

2645 1540

1540 2660

2660 3065

3065 3095

3095 3650

3650 3680

3680 4255

4255 4355

4355 4370

4370 3630

3630 3635

3635 4245

4245 4445

4445 4609

4609 4710

4710 5435

5435 5475

5475 5610

5610 5711

5711 6150

6150 6170

6170 6180

6180 6270

6270 6290

6290 6445

6445 6499

6499 6614

6614 6713

6713 7465

7465 7495

7495 7614

7614 7622

7622 7715

7715 7726

7726 8210

8210 8270

8270 8650

8650 8727

8727 GC1705

GC1705 1464 Loader

1464 Loader 1466 Loader

1466 Loader 1040 Loader

1040 Loader 1070 Loader

1070 Loader 905 Loader

905 Loader 906 Loader

906 Loader 915 Loader

915 Loader 916 Loader

916 Loader 921 Loader

921 Loader 926 Loader

926 Loader 931 Loader

931 Loader 933 Loader

933 Loader 936 Loader

936 Loader 938 Loader

938 Loader 939 Loader

939 Loader 940 Loader

940 Loader 941 Loader

941 Loader 945 Loader

945 Loader 946 Loader

946 Loader 948 Loader

948 Loader 949 Loader

949 Loader 950 Loader

950 Loader 951 Loader

951 Loader 955 Loader

955 Loader 956 Loader

956 Loader 958 Loader

958 Loader 960 Loader

960 Loader 961 Loader

961 Loader 965 Loader

965 Loader 966 Loader

966 Loader 968 Loader

968 Loader 975 Loader

975 Loader 976 Loader

976 Loader 978 Loader

978 Loader 985 Loader

985 Loader FL.3114 X

FL.3114 X FL.3419 X

FL.3419 X FL.3522

FL.3522 FL.3615

FL.3615 FL.3619

FL.3619 FL.3817

FL.3817 FL.3819

FL.3819 FL.3823

FL.3823 FL.4018

FL.4018 FL.4121

FL.4121 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader FL.4125

FL.4125 FL.4227

FL.4227 FL.4124

FL.4124 FL.4220

FL.4220 FL.4323

FL.4323 FL.4327

FL.4327 FL.4621

FL.4621 FL.4624

FL.4624 FL.4628

FL.4628 FL.5033

FL.5033 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader 1010

1010 1020

1020 1030

1030 1035

1035 1040

1040 1045

1045 1080

1080 1085

1085 1120

1120 1125

1125 1140

1140 1160

1160 1165

1165 1180

1180 1190

1190 1205

1205 1210

1210 1215

1215 1220

1220 1225

1225 1230

1230 1233

1233 1235

1235 1240

1240 1260

1260