________________________________________________________________________________

Massey Ferguson 6465, 6480, 6485 - Rear axle brake pistons

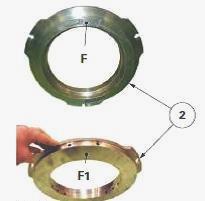

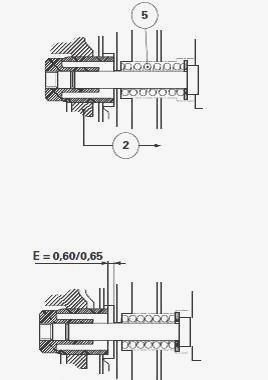

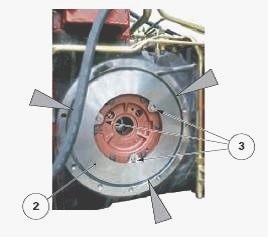

The brake pistons (2) are housed in two cavities formed by the centre

housing and the left and right-hand differential supports. They are:

concentric with the mating face of each trumpet housing; guided by three

stop pins (6) force fitted into the centre housing. Each brake piston

has two ring faces F and F1, which have different cross sections.

Face F is under hydraulic pressure: from the master cylinders (MF 6465,

6480 tractors); from a block/valves assembly (MF 6485, 6490 tractors).

Face F1 compresses the brake disc, which is splined to the input sun

gear of the trumpet housing, against the compartment or spacer,

depending on the trumpet housing type. The compartment or spacer also

acts as a brake plate. The pistons are sealed by "O"rings (3) (4)

mounted respectively into the grooves of the centre housing and the

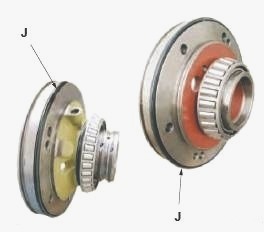

differential supports. A seal J placed in the angle of each support

prevents the pressure in the piston chamber from escaping into the

centre housing.

MF 6465, 6480 Tractors fitted with GTA-1040 transmission (40

kph)

Each brake piston is controlled by a master-cylinder assisted

hydraulically by the 21 bar low-pressure system (pressure P). When the

brake is released, minimal clearance is ensured between the brake piston

and disc. The brakes are self-adjusting. They maintain constant pedal

clearance.

MF 6485, 6490 Tractors fitted with GTA-1540 transmission (50

kph)

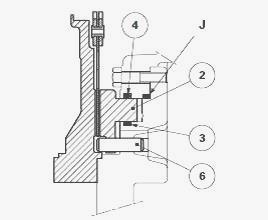

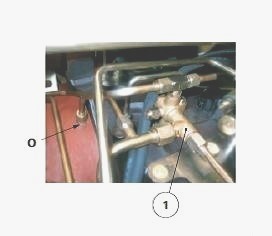

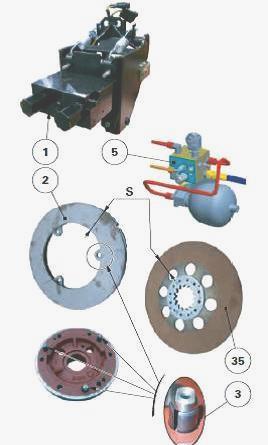

For MF 6485, 6490 tractors fitted with GTA-1540 transmission (50 kph)

and depending on the legal requirements of certain countries where the

tractor is registered with a maximum speed of 50 kph, the hydraulic

control of the brakes is fitted with: block/valves assembly (1) fitted

to the front bulkhead of the cab and activated by the brake pedals;

electronically controlled 50 kph accumulator and a hydraulic braking

unit (5) located on the right-hand side of the transmission; brake

pistons (2) and discs (35) fitted in the centre housing cavities and

designed with a greater braking surface S than that of the brake pistons

and discs on 40 kph tractors; return travel limit mechanism (3) for each

brake piston.

Massey Ferguson 6465, 6480, 6485, 6490 -

Operation of the return travel limit mechanism of the brake pistons

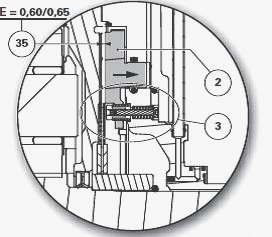

Brakes active

When the brake pistons (2) are pressurised by the block/valves assembly

(1) and the 50 kph hydraulic braking unit (5), they compress the brake

discs and drive the elements (4) (1) (7) and (6) of the return travel

limit mechanism. At the same time, the springs (5) compress by 0.60 to

0.65 mm depending on space E in order to fit the flat washers (6)

against the differential supports. Any wear to the brake discs (35) is

automatically corrected by the "tight" sliding of the brake discs (2) on

the Mecanindus pins (4).

Brakes inactive

When the brake pedal is released and the hydraulic pressure drops in the

brake piston chamber (2), the springs (5) decompress to the limit of E

(0.60 to 0.65 mm), thus separating the pistons (2) of the brake discs by

the same value.

Lubrication

The brake discs are cooled during use by a flow of oil coming from the

lubrication system and flowing towards the hydraulic manifold (1) and

port O via the right-hand hydraulic cover plate. Oil flows between the

brake discs and pistons and lubricates their braking surfaces when they

are not in use. On Normal Duty trumpet housings, the brake discs are

lubricated by union R screwed directly onto each trumpet housing.

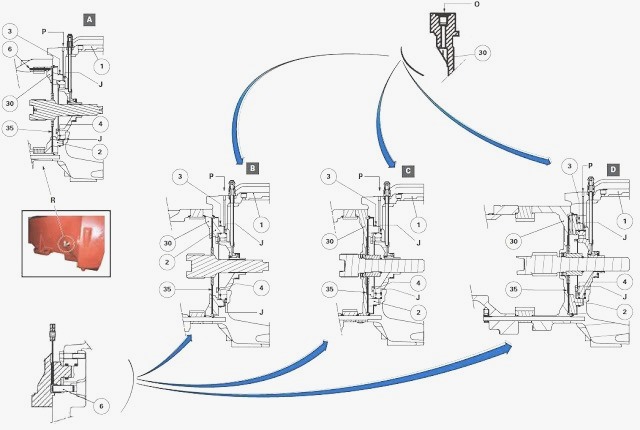

Parts list: (2) Brake piston (3) "O" ring (4) "O" ring

(6) Stop pins (30) Compartment or spacer (depending on type of trumpet

housing) (35) Brake disc, A - Brake mechanism without compartment (the

trumpet housing is thrust directly against the centre housing), B -

Brake mechanism with single compartment, C - Brake mechanism with sealed

compartment, D - Brake mechanism with spacer, J - Seals, O - Port for

lubrication of brake discs, P - Pressure emitted by the master

cylinder(s) (MF 6465, 6480 tractors) or a block/valve assembly (MF 6485,

6490 tractors), R - Union

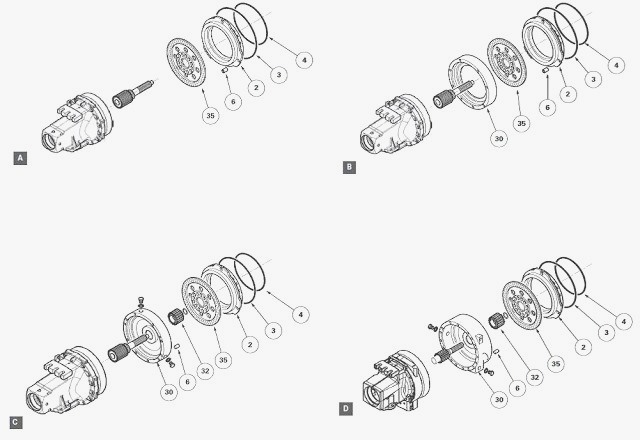

Parts list: (2) Brake piston (3) "O" ring (4) "O" ring

(6) Stop pins (30) Compartment or spacer (depending on type of trumpet

housing) (32) Hub (Heavy Duty sealed trumpet housing versions and

trumpet housings with composite final drive) (35) Brake disc, A - Brake

mechanism without compartment (the trumpet housing is thrust directly

against the centre housing), B - Brake mechanism with single

compartment, C - Brake mechanism with sealed compartment, D - Brake

mechanism with spacer

Massey Ferguson 6465, 6480, 6485, 6490 -

Removing and refitting a brake piston

Brake piston removal

Remove the trumpet housing(s).

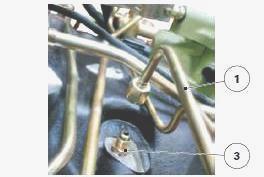

Disconnect the brake supply pipe (1) located above the centre housing

that comes from the brake master cylinder. For tractors fitted with

GTA1540 transmission (50 kph), the brake supply pipe (1) comes from the

block/valves (1) fitted to the cab's front bulkhead.

Using a manual hydraulic pump connected to the union (3), drive out the

piston (2) from the centre housing.

Remove the "O" rings (3) (4) fitted respectively on the centre housing

and the differential support. "O" rings J, located between the

differential supports and the centre housing, seal the brake piston

chambers.

If seal(s) is/are to be replaced, remove the differential support(s).

Brake piston refitting

Clean and check all components. Replace those that are defective. In

particular, check the wear on the brake plate, the sealed compartment or

the spacer (depending on type of trumpet housing). If removed, refit the

differential support(s) fitted with a new "O" ring J. Before the final

refitting of the piston (2), test fit the piston in the centre housing,

temporarily excluding the "O" rings (3) (4). This temporary fitting

allows you to check that the piston can move freely in its bore and on

its stop pins. During fitting, any friction points must be eliminated

and problem parts must be identified. Remove all impurities from the

piston chamber. Definitively refit the piston, but only after a

satisfactory test fitting has been carried out.

Lubricate the new "O" rings (3) (4) with clean transmission oil. Fit

them into their respective grooves (centre housing and differential

support). If possible, turn the brake piston so that the majority of the

lubricating ports around its rim are facing upwards (depending on piston

type). Fit the piston into the centre housing by aligning its pin

housings with the stop pins (6). Fit the piston (2) using a makeshift

tool and two screws V of suitable length. These two screws are tightened

gradually and alternately during the fitting process. For tractors

fitted with GTA1540 transmission (50 kph), carefully monitor the fitting

of the piston inside its return travel limit mechanism (3).

If necessary, fit by gently tapping with a plastic hammer in

diametrically opposed positions around the piston rim. The return travel

limit mechanism (3) means you have to push the brake pistons right back

to the bottom of their cavity (pushing the brake pistons is made easier

by gently unscrewing the centre housing and the bleed valves or pipes

coming from the block/valve assembly). In this way, the mechanism (3)

can once again return the brake pistons correctly if one or more of the

following components has been replaced: brake discs; brake plates,

compartment (single or sealed) or spacer (depending on the type of

trumpet housing); brake pistons and/or "O" rings (3) (4). Remove the

tool. Check that there are no seal fragments on the piston

circumference.

MF 6465, 6480, 6485, 6490 - Brake piston leak

test

The brake piston leak test can only be carried out correctly if the

pressure gauge and compressed air supply line are completely sealed.

Figure shows a simplified pressure gauge design. Other more complex

pressure gauges can also be used. Fit the tool used to retain the piston

(2) against the centre housing. Connect the pressure gauge to the union

(3). Supply the brake piston with compressed air at approximately 3 bar

to position the seals (3) (4) in their respective groove. Close the

valve. Disconnect the compressed air source. Open the valve.

Supply the system again at approximately 0.3-0.4 bar to test the

tightness of the seals (3) (4). Close the valve. Check that the pressure

gauge needle remains still for approximately one minute. Shut the

compressed air inlet when the test proves satisfactory. Remove: pressure

gauge; piston retaining tool. Reconnect the brake supply pipe. Refit the

trumpet housing (s). Thoroughly bleed the brake system. Road test the

main brakes. Check tightness of: trumpet housing seals; unions and the

pipes (brake supply and lubrication pipes).

Massey Ferguson 6485, 6490 - Disassembling,

reassembling and adjusting the return travel limit mechanism of the

brake piston

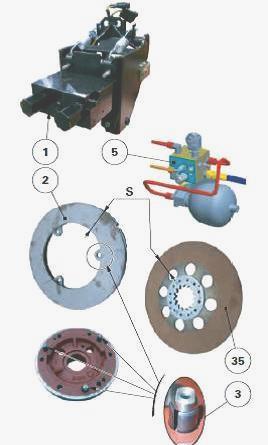

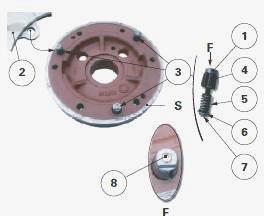

On MF 6485, 6490 tractor each brake piston (2) is assisted by a return

travel limit mechanism. This mechanism, which comprises three assemblies

(3), allows: piston to release itself from the brake disc by approx. 0.7

mm when the brakes are inactive; "drag" effect to be minimised.

The three assemblies (3) occupy an equidistant position on each

differential support S. An assembly comprises: M6 x 40 screw (7); flat

washer (6); spring (5); Mecanindus pin (4); shouldered nut with flat

sections (1); locking screw (8).

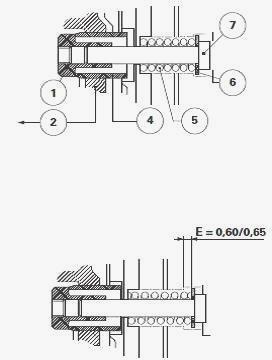

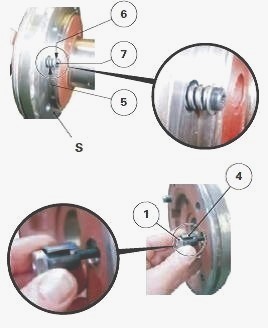

Return travel limit mechanism disassembly

The differential support(s) must be removed in order to disassemble the

brake piston's return travel limit mechanism. Remove: brake piston(s)

(2); differential support(s) S. Place the differential support(s) on a

workbench.

On faces F and F1 of differential support(s) S, remove an assembly (3)

including: locking screw (8); shouldered nut with flat sections (1)

(support the M6 screw (7)); Mecanindus pin (4); M6 screw (7); flat

washer (6); spring (5). Repeat step for the other two assemblies (3).

Return travel limit mechanism reassembly

Clean and check all components. Replace those that are defective.

On faces F and F1 of differential support(s) S, refit: M6 screw (7);

flat washer (6); spring (5); Mecanindus pin (4); shouldered nut with

flat sections (1), with its thread lightly smeared with Loctite 243 or

equivalent.

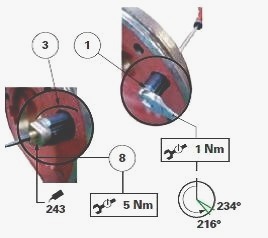

Settings

Adjust each assembly (3) of the brake piston's return travel limit

mechanism, proceeding as follows for each assembly: Tighten the

shouldered nut (1) with flat sections (M6, 100 pitch) to a torque of

approximately 1 Nm (spring coils almost joined).

Slacken off this nut between approximately half and three quarters of a

turn: this corresponds to an anti-clockwise rotation of 216° to 234° or

60% to 65% of a turn. By adjusting each assembly (3) of the return

travel limit mechanism in this way, a gap E of approx. 0.60 to 0.65 mm

is achieved between the piston (2) and the brake disc (35) when the main

brake is inactive.

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF FRONT END LOADERS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS MAINTENANCE |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS TROUBLESHOOTING | ||||

| 1652 | 1749 | 2620 | 2725 | 2805 |

| 3050 | 3120 | 3640 | 3709 | 4245 |

| 4455 | 5320 | 5455 | 5613 | 6150 |

| 6280 | 6480 | 6615 | 7618 | 7720 |

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS 130

130 133

133 145

145 155

155 158

158 165

165 175

175 185

185 188

188 230

230 254

254 254S

254S 284S

284S 294

294 353

353 290

290 362

362 375

375 390

390 398

398 399

399 590

590 690

690 1010

1010 1030

1030 1020

1020 1150

1150 2620

2620 2640

2640 2645

2645 1540

1540 2660

2660 3065

3065 3095

3095 3650

3650 3680

3680 4255

4255 4355

4355 4370

4370 3630

3630 3635

3635 4245

4245 4445

4445 4609

4609 4710

4710 5435

5435 5475

5475 5610

5610 5711

5711 6150

6150 6170

6170 6180

6180 6270

6270 6290

6290 6445

6445 6499

6499 6614

6614 6713

6713 7465

7465 7495

7495 7614

7614 7622

7622 7715

7715 7726

7726 8210

8210 8270

8270 8650

8650 8727

8727 GC1705

GC1705 1464 Loader

1464 Loader 1466 Loader

1466 Loader 1040 Loader

1040 Loader 1070 Loader

1070 Loader 905 Loader

905 Loader 906 Loader

906 Loader 915 Loader

915 Loader 916 Loader

916 Loader 921 Loader

921 Loader 926 Loader

926 Loader 931 Loader

931 Loader 933 Loader

933 Loader 936 Loader

936 Loader 938 Loader

938 Loader 939 Loader

939 Loader 940 Loader

940 Loader 941 Loader

941 Loader 945 Loader

945 Loader 946 Loader

946 Loader 948 Loader

948 Loader 949 Loader

949 Loader 950 Loader

950 Loader 951 Loader

951 Loader 955 Loader

955 Loader 956 Loader

956 Loader 958 Loader

958 Loader 960 Loader

960 Loader 961 Loader

961 Loader 965 Loader

965 Loader 966 Loader

966 Loader 968 Loader

968 Loader 975 Loader

975 Loader 976 Loader

976 Loader 978 Loader

978 Loader 985 Loader

985 Loader FL.3114 X

FL.3114 X FL.3419 X

FL.3419 X FL.3522

FL.3522 FL.3615

FL.3615 FL.3619

FL.3619 FL.3817

FL.3817 FL.3819

FL.3819 FL.3823

FL.3823 FL.4018

FL.4018 FL.4121

FL.4121 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader FL.4125

FL.4125 FL.4227

FL.4227 FL.4124

FL.4124 FL.4220

FL.4220 FL.4323

FL.4323 FL.4327

FL.4327 FL.4621

FL.4621 FL.4624

FL.4624 FL.4628

FL.4628 FL.5033

FL.5033 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader 1010

1010 1020

1020 1030

1030 1035

1035 1040

1040 1045

1045 1080

1080 1085

1085 1120

1120 1125

1125 1140

1140 1160

1160 1165

1165 1180

1180 1190

1190 1205

1205 1210

1210 1215

1215 1220

1220 1225

1225 1230

1230 1233

1233 1235

1235 1240

1240 1260

1260