________________________________________________________________________________

Massey Ferguson 6465, 6480, 6485 - Park Lock

The Park Lock is a parking brake mechanism located above the GPA40 rear

axle. It is designed to immobilise the tractor in complete safety. The

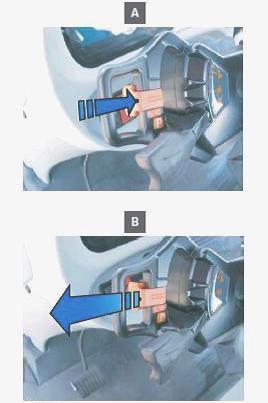

Park Lock is easily controlled via a pushbutton located to the left of

and below the steering wheel. This pushbutton enables the operator to

select the Park Lock engaged position (A) or the disengaged position (B)

while seated in the operator's seat. The Park Lock mainly comprises

three parts: hydraulic part, electrical part, mechanical part.

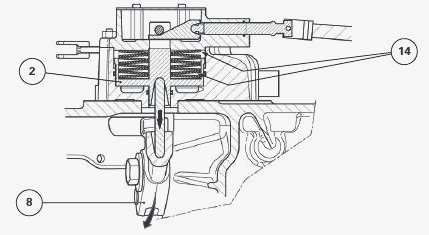

Hydraulic part

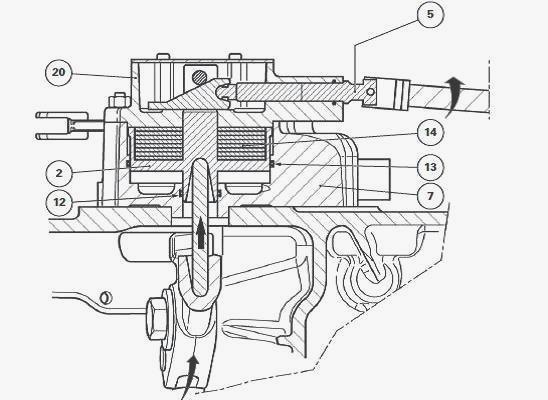

The hydraulic part is located above the rear axle inside the Park Lock

unit (7)/cover plate (20) assembly. It comprises: two "O" rings (12) and

(13), piston (2), which is returned by a set of eight.

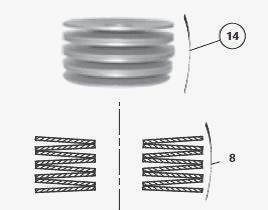

Belleville washers (14). The effect of the load exerted on the piston

(2) by the Belleville washers may be cancelled by fully screwing the

special hexagonal head screw (5). Cancelling the load exerted by the

Belleville washers is useful if: it is necessary to disassemble the Park

Lock, Hydraulic and/or electronic problem occurs, which hinders tractor

mobility.

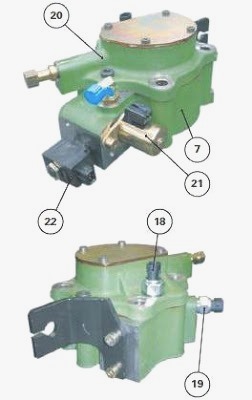

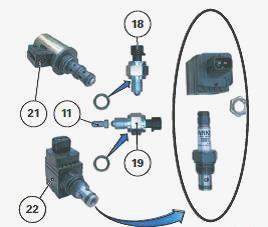

Electrical part

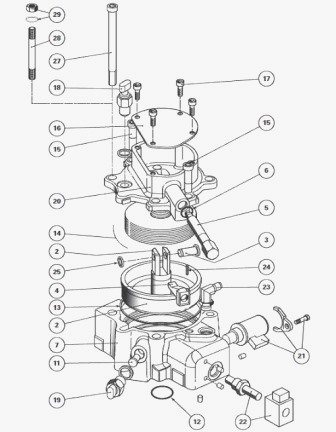

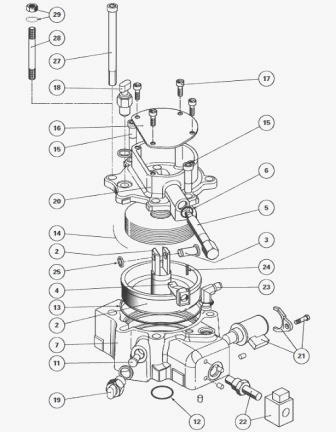

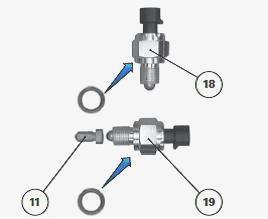

The electrical part comprises: two solenoid valves (21) and (22), two

switches (18) and (19). The solenoid valves and switches are screwed

onto the Park Lock unit (7) and the cover plate (20) respectively. They

are managed by the MF 6465, 6480, 6485, 6490 tractor's electronic system

and via the connectors.

Mechanical part

The mechanical part of the Park Lock uses the components and the

operating principle which are an extension of the hand brake mechanism.

Here is a reminder of the components used: Actuator lever, Discs,

Intermediate plates, Mechanism.

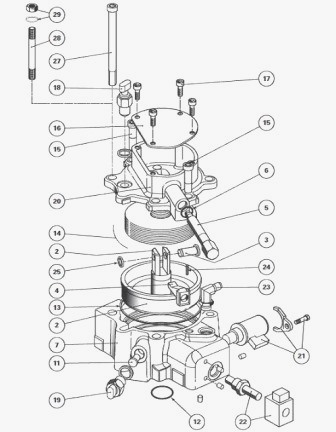

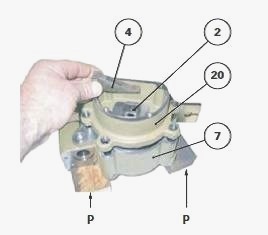

Parts list: (1) Park Lock (2) Piston (3) Pin (4) Wedge

(5) Special screw (manual disengagement) (6) "O" ring (7) Park Lock unit

(8) Actuator lever (9) Screw (10) Push rod (11) Pushrod (12) "O" ring

(13) "O" ring (14) Belleville washers (15) Screw (16) Cover plate (17)

Screw (18) Switch (19) Switch (20) Cover plate (21) Solenoid valve (22)

Solenoid valve (23) 17 or 21 bar union (24) Mecanindus pin (25) Circlip

(26) Tie rod (27) Screw (28) Stud (29) Washer/nut (M) Hand brake

mechanism

Massey Ferguson 6465, 6480, 6485, 6490 - Park

Lock Operation

Engaged position: mechanical action

The movement of the piston (2) caused when the Belleville washers (14)

are released forces the actuator lever (8) to tilt, compressing the hand

brake discs splined in rotation with the pinion. The rear axle is then

blocked and the tractor is immobilised.

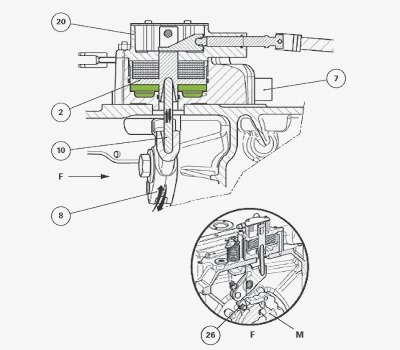

Disengaged position: hydraulic action

In this configuration, the Park Lock mechanism receives a 17 or 21 bar

oil supply via two different solenoid valves. The piston (2) then

compresses the Belleville washers and releases the push rod (10), the

mechanism (M) and the hand brake discs via the actuator lever (8) and

the hand brake tie rod (26). One of the two solenoid valves secures the

Park Lock disengaged position in the event of a fault. The principle

consists of maintaining the oil chamber of the piston (2) under pressure

by shutting off its return line. A switch screwed onto the cover plate

(20) and a second switch located on the Park Lock unit (7) check the

hand brake disc wear and operation of the Park-Lock respectively via

indicator lights. Each electrical component is controlled by the

tractor's electronic system.

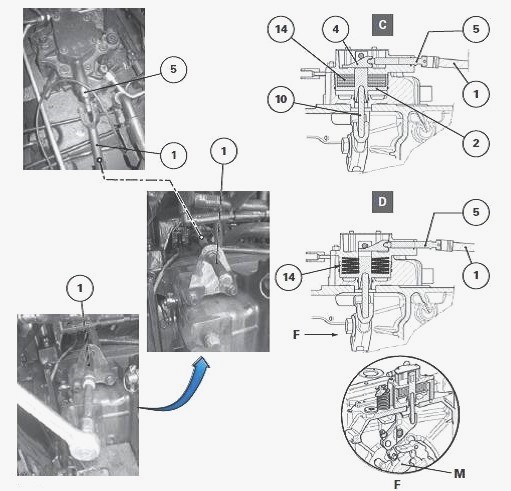

MF 6465, 6480, 6485, 6490 - Manual

disengagement and engagement of the Park Lock

Manual disengagement

If manual disengagement is necessary - The Park Lock must be disengaged

manually: if the rear axle is to be removed for dismantling, to provide

tractor mobility in the event of a failure on the 17 or 21 bar hydraulic

system or a fault on the electronic management system.

Using the remote control (1) linked to the special screw (5) on the

cover plate, manually disengage the Park Lock by fully screwing in the

special screw (5) until it no longer turns.

Description of the mechanical reaction during manual disengagement -

When the special screw (5) is screwed in, the wedge (4) moves. This

beveled wedge mechanically pulls the piston (2) upwards, compressing the

set of Belleville washers (14). The load which had been applied to the

push rod (10) is cancelled. The mechanism (M) and the hand brake discs

are then released to make the tractor mobile.

Manual engagement

If for whatever reason the Park Lock has been disengaged, using the

remote control (1), completely unscrew the special screw (5) until it

comes into contact with a "hard" point. This procedure restores the Park

Lock original functions: disengagement (hydraulic function) and

engagement (mechanical function).

Massey Ferguson 6465, 6480, 6485, 6490 -

Removing and install the Park Lock unit

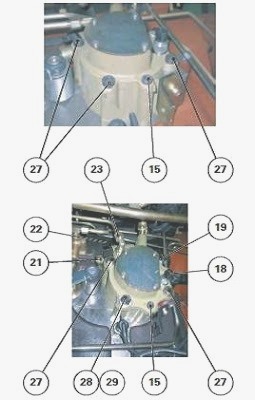

Remove the components restricting access to the Park Lock unit.

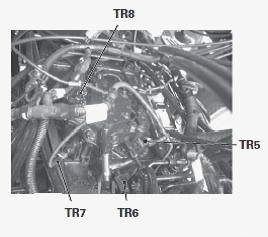

Disconnect the connectors (TR5) to (TR8) connected to the switches (18)

and (19) and the solenoid valves (21) and (22), marking them beforehand.

Disconnect the 17 or 21 bar supply pipe connected to the union (23).

Manually disengage the Park Lock.

Removal

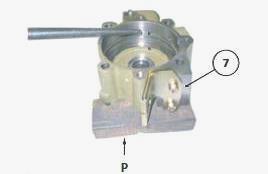

Remove the M12 screws (27) and the nut (29) (if fitted) but not the M10

screws (15). Separate and remove the Park Lock from the centre housing.

Recover the push rod (10) without allowing it to fall inside the centre

housing.

Install

Clean the mating face of the Park Lock on the centre housing and on the

unit (7). Smear the bottom end of the push rod (10) with Molykote type

grease or equivalent. Reinstall this rod into it compartment on the

actuator lever (8). Replace the two "O" rings providing the seal between

the Park Lock unit (7) and the centre housing. Smear the housing of the

piston (2) with Molykote type grease or equivalent. Position and refit

the Park Lock, fitting the upper end of the push rod (10) into the

compartment on the piston (2). Lightly smear the thread of the screws

(27) and the thread of the nut (29) (if fitted) with Loctite 542 or

equivalent. The thread of the screws and the stud (28) (if removed) must

be smeared with Loctite as their ends protrude inside the centre

housing. Tighten the screws (27) and the nut (29) to 100 to 130 Nm.

Reinstall the components which were taken off for hindering the removal

of the Park Lock unit. Restore the original functions to the Park Lock

(disengagement and engagement) by completely unscrewing the special

screw (5). Reconnect the 17 or 21 bar supply pipe connected to the union

(23). Reconnect the connectors (TR5) to (TR8) to the switches (18) and

(19) and the solenoid valves (21) and (22). Start the tractor engine.

Slowly move the tractor several meters over a track with a slight slope

and immediately place the shuttle lever back in the neutral position.

Before stopping the tractor, push the pushbutton to engage the Park-Lock

and carry out an initial test. When engaging the Park Lock, check that

the tractor is immobilized by noting a slight hesitation caused by the

transmission locking. Repeat the above procedure several times to

confirm that the Park Lock is operating correctly. While seated in the

operator's seat, move the tractor onto a track with a steeper slope.

Stop the engine and check: efficiency of the Park Lock, that the hand

brake is operating correctly. Check that there are no leaks in the

hydraulic system (union, mating face, switches and solenoid valves).

Massey Ferguson 6465, 6480, 6485, 6490 -

Disassembling and reassembling the Park Lock unit

Remove the Park Lock comprising the unit (7) and the cover plate (20).

Unscrew and remove: solenoid valves (21) and (22), switches (18) and

(19) fitted with their seal.

These switches are located on the cover plate (20) and on the unit (7)

respectively. Recover the pushrod (11). The pushrod (11) acts as a

transmission component between the switch (19) and the piston (2).

Park Lock unit disassembly

Completely unscrew the special screw (5) so that the Park Lock is in the

manual and as a result, the Belleville washers (14) are almost released.

Unscrew the screws (17). Release and remove the cover plate (16). Remove

the circlip (25) and the pin (3).

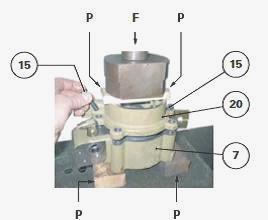

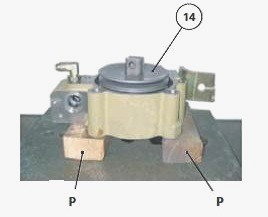

Place the Park Lock in a press, protecting the underside of the unit (7)

using two pieces of flexible protection (P). Also slide a flexible

protection (P) over the cover plate (20). Apply the hydraulic press ram

to the flexible protection (P) without exerting any force (F) on the

cover plate (20). Unscrew the screws (15). Slowly decompress the

hydraulic press ram to decompress the Belleville washers (14). Remove:

cover plate (20), Belleville washers (14), first noting their number and

positioning The eight Belleville washers are referenced in the spare

parts catalogue in the form of a kit.

On the cover plate (20): Drive out the spring pins (24). Completely

unscrew the special screw (5). Recover the wedge (4). Remove the "O"

ring (6) and discard it

Take out the piston (2) from the Park Lock unit (7). Remove and discard

the "O" rings (12) (13).

Park Lock unit reassembly

Clean: mating faces of the Park Lock unit (7); all parts. Using a jet of

compressed air or a flexible iron wire, check that the hydraulic

channels of the Park Lock unit (7) are not blocked. Check: that the

pushrod (11) for the switch (19) moves freely in its housing; that there

is a rivet fitted to the outer end of each hydraulic channel of the Park

Lock unit (7). Temporarily remove the seals (12) and (13) from the

piston (2). Test fit the latter inside the Park Lock unit (7). Check

that the piston moves freely inside its bore with no "hard" points.

Eliminate any impurities that may have become accidentally lodged inside

the chamber of the piston (2). Lubricate the seals (12) and (13) with

clean transmission oil. Install these seals into the grooves of the Park

Lock unit (7). Hold the piston (2) above the Park Lock unit (7),

positioning its flat section so that it is facing towards the return

port.

Install the piston (2), gently tapping its centre in a circular motion

using a plastic hammer. After fitting, check that there are no fragments

of seal around the piston. Lightly smear the upper mating face of the

Park-Lock unit with Loctite 5206 or equivalent. Reinstall the Belleville

washers (14).

Install and position the cover plate (20) on the Park Lock unit (7).

Test fit to check that the wedge (4) is correctly aligned with the

clevis of the piston (2). If the alignment is incorrect, correct it.

Place the Park Lock in a press, using the same protections that were

used for removal. Using the ram press, exert a moderate force (F) on the

cover plate (20) so as to compress the Belleville washers. As soon as

the cover plate (20) reaches the ParkLock unit (7), screw on and tighten

the two screws (15) to 57-77 Nm. Lubricate the "O" ring (6). Install it

into the groove of the cover plate (20). On the cover plate (20), screw

on the special screw (5) and fit the wedge (4) at the same time. Form a

wedge/special screw assembly using two new spring pins. Lightly smear

the upper mating face of the cover plate (20) with Loctite 5206 or

equivalent. Reinstall the cover plate (16). Tighten the screws (17) to a

torque of 12 to 16 Nm. Ensure that each switch is fitted with a new

seal.

Install: switch (18) onto the cover plate (20); pushrod (11) and the

switch (19) to the ParkLock unit (7). Tighten the switches to a torque

of 15-25 Nm. Install the solenoid valves (21) (22) in the same positions

as before disassembly. Tighten the following onto the solenoid valve

(22): spool to a torque of 18-20 Nm; solenoid to a torque of 4-5 Nm.

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF FRONT END LOADERS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS MAINTENANCE |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS TROUBLESHOOTING | ||||

| 1652 | 1749 | 2620 | 2725 | 2805 |

| 3050 | 3120 | 3640 | 3709 | 4245 |

| 4455 | 5320 | 5455 | 5613 | 6150 |

| 6280 | 6480 | 6615 | 7618 | 7720 |

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS 130

130 133

133 145

145 155

155 158

158 165

165 175

175 185

185 188

188 230

230 254

254 254S

254S 284S

284S 294

294 353

353 290

290 362

362 375

375 390

390 398

398 399

399 590

590 690

690 1010

1010 1030

1030 1020

1020 1150

1150 2620

2620 2640

2640 2645

2645 1540

1540 2660

2660 3065

3065 3095

3095 3650

3650 3680

3680 4255

4255 4355

4355 4370

4370 3630

3630 3635

3635 4245

4245 4445

4445 4609

4609 4710

4710 5435

5435 5475

5475 5610

5610 5711

5711 6150

6150 6170

6170 6180

6180 6270

6270 6290

6290 6445

6445 6499

6499 6614

6614 6713

6713 7465

7465 7495

7495 7614

7614 7622

7622 7715

7715 7726

7726 8210

8210 8270

8270 8650

8650 8727

8727 GC1705

GC1705 1464 Loader

1464 Loader 1466 Loader

1466 Loader 1040 Loader

1040 Loader 1070 Loader

1070 Loader 905 Loader

905 Loader 906 Loader

906 Loader 915 Loader

915 Loader 916 Loader

916 Loader 921 Loader

921 Loader 926 Loader

926 Loader 931 Loader

931 Loader 933 Loader

933 Loader 936 Loader

936 Loader 938 Loader

938 Loader 939 Loader

939 Loader 940 Loader

940 Loader 941 Loader

941 Loader 945 Loader

945 Loader 946 Loader

946 Loader 948 Loader

948 Loader 949 Loader

949 Loader 950 Loader

950 Loader 951 Loader

951 Loader 955 Loader

955 Loader 956 Loader

956 Loader 958 Loader

958 Loader 960 Loader

960 Loader 961 Loader

961 Loader 965 Loader

965 Loader 966 Loader

966 Loader 968 Loader

968 Loader 975 Loader

975 Loader 976 Loader

976 Loader 978 Loader

978 Loader 985 Loader

985 Loader FL.3114 X

FL.3114 X FL.3419 X

FL.3419 X FL.3522

FL.3522 FL.3615

FL.3615 FL.3619

FL.3619 FL.3817

FL.3817 FL.3819

FL.3819 FL.3823

FL.3823 FL.4018

FL.4018 FL.4121

FL.4121 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader FL.4125

FL.4125 FL.4227

FL.4227 FL.4124

FL.4124 FL.4220

FL.4220 FL.4323

FL.4323 FL.4327

FL.4327 FL.4621

FL.4621 FL.4624

FL.4624 FL.4628

FL.4628 FL.5033

FL.5033 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader 1010

1010 1020

1020 1030

1030 1035

1035 1040

1040 1045

1045 1080

1080 1085

1085 1120

1120 1125

1125 1140

1140 1160

1160 1165

1165 1180

1180 1190

1190 1205

1205 1210

1210 1215

1215 1220

1220 1225

1225 1230

1230 1233

1233 1235

1235 1240

1240 1260

1260