________________________________________________________________________________

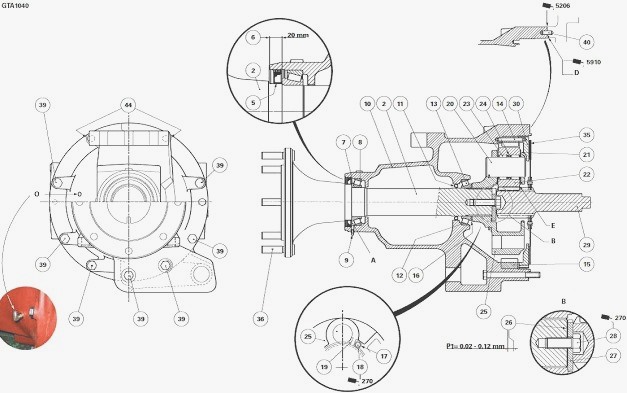

Massey Ferguson 6465, 6480, 6490 - Rear axle planet carrier

Massey Ferguson 6465, 6480, 6490 Rear axle -

Removing and refitting, disassembling and reassembling the planet

carrier

Removal

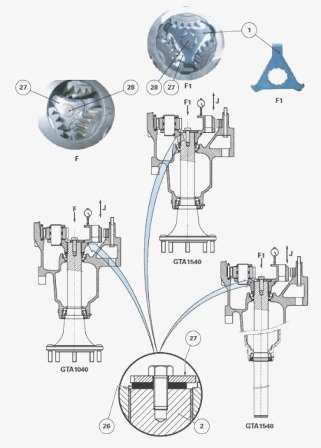

MF 6465, 6480 Tractor - Remove the trumpet housing

assembly. If possible, place it in a vertical position with the planet

carrier facing upwards. Immobilise the axle shaft or the planet carrier

(25). Remove: M20 screw (28); tripod washer (27); shim(s) (26); planet

carrier (25) of the ring gear.

MF 6485, 6490 Tractor - Remove the trumpet housing

assembly. If possible, place it in a vertical position with the planet

carrier facing upwards. Immobilise the axle shaft or the planet carrier

(25). Remove: lock washer (1). The lock washer is fixed with Loctite

401; M20 screw (28); tripod washer (27); shim(s) (26); planet carrier

(25) of the ring gear.

Disassembly

Remove: screw (18); spacer (17); snap ring (19) by moving its two ends

apart. Using a hammer, tap gently on the three pins (20). Remove the

three pins and the snap ring. Remove: three planet gears (22); needle

rollers (23); spacers (24); friction washers (21).

Reassembly

Clean the planet carrier, the pins and the planet gears. Check the

parts. Smear the needle rollers with miscible grease. Fit each planet

gear with two rows of needle rollers (23) separated by a spacer (24).

Fit the planet gears. Centre the friction washers (21) in the planet

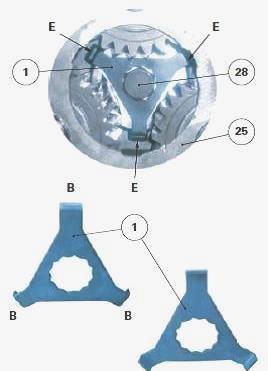

carrier. Imprint E on one surface of the planet gears (22) (punch mark

or groove) must face the opposite way to the splined hub of the planet

carrier. Engage the three pins (20) with the snap ring (19).

Open the snap ring (19). Tap gently on the three pins so that the snap

ring fits into the groove of the planet carrier. Manually check the

axial clearance of each planet gear. Position one end of the snap ring

against the pin (20). Clean the thread of the screw (18) and the tapped

hole for this screw in the planet carrier. Fit the spacer (17). Fit and

tighten the screw to 34-50 Nm, after lightly smearing its thread with

Loctite 270 or equivalent.

Refitting

MF 6465, 6480 Tractor - Check that the tab washer (16) is present. Refit

the planet carrier (25). If necessary, shim the tapered roller bearings

of the axle shaft. Immobilise the axle shaft (2) or the planet carrier

(25). Refit the shim(s) (26) and the tripod washer (27). Screw in and

tighten the M20 screw (28) to 374-506 Nm after lightly smearing its

thread with Loctite 270 or equivalent. Refit the trumpet housing

assembly.

MF 6485, 6490 Tractor -

Check for the presence of the tab washer (16). Refit the planet carrier

(25). If necessary, shim the tapered roller bearings of the axle shaft.

Immobilise the axle shaft (2) or the planet carrier (25). Refit the

shim(s) (26) and the tripod washer (27). Screw in and tighten the M20

screw (28) to 410 Nm. Slide a lock washer (1) onto the head of the M20

screw (28). Ensure its tabs B are correctly housed in moulded slots E of

the planet carrier (25).

If this is not the case, repeat the step with the second lock washer; if

this is still not the case, repeat the step with the third. Three lock

washers (1) are available from the spare parts catalogue. Each of the

lock washers has a 10° angular offset.

Case 1: A lock washer is selected - Apply three spots of Loctite 401 or

equivalent to the mating face of the selected lock washer which is

turned towards the tripod washer (27). Loctite 401 prevents the lock

washer (1) from moving when the trumpet housing is being refitted to the

centre housing. When the trumpet housing is refitted, the sun gear (29)

holds the lock washer in place. Case 2: No lock washer is selected -

Gently retighten the M20 screw (28), taking care not to exceed the

maximum torque of 560 Nm. Refit the trumpet housing assembly.

Massey Ferguson 6465, 6480, 6490 - Replacing tapered roller bearings and

seals

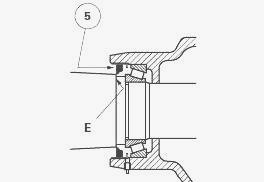

Disassembly

Remove: trumpet housing assembly; planet carrier (25). Remove: tab

washer (16); axle shaft (2); bearing cone (13). If necessary, extract:

bearing cone (7); seals (5) (11) and discard them. Using a suitable

puller or a makeshift tool, extract or drive out: bearing cups (8) (12);

friction cage (6).

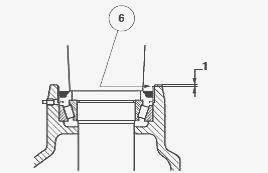

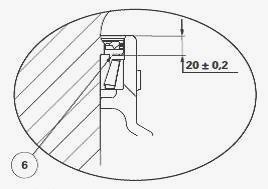

Reassembly

Clean and check all components. Replace those that are defective. Smear

the external surface of the seal (11) with a film of clean transmission

oil. Using a suitable fitting drift, fit the seal (11) to within

approximately 8 mm of the shoulder of the cup (12) on the trumpet

housing, positioning its lip towards the bearing cone. If a groove has

been worn into the axle shaft at the location of the old seal (11),

offset the new seal slightly so that its lip ensures the axle shaft is

completely sealed beyond the worn groove. Fit: bearing cups (8) (12)

against their respective shoulders; friction cage (6) according to the

distance indicated.

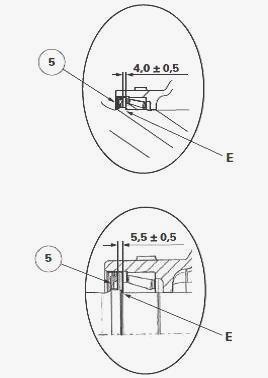

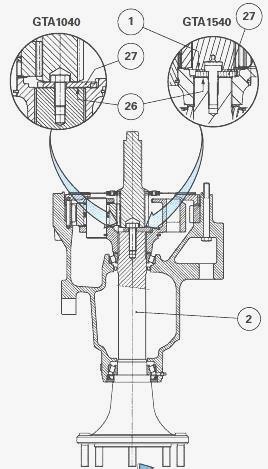

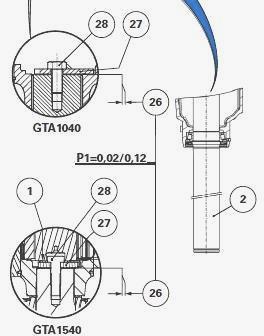

MF 6465, 6480 tractors fitted with GTA1040 transmission

MF 6485, 6490 tractors fitted with GTA1540 transmission

MF 6465, 6480 Tractor -

Fit the new three-lipped seal (5) level with shoulder E of the flanged

axle shaft or straight axle shaft. Fit the bearing cone against its

shoulder on the flanged axle shaft or straight axle shaft using a

suitable tool.

MF 6485, 6490 Tractor -

Fit the new three-lipped seal (5): 4.0 ± 0.5 mm from shoulder E of the

flanged axle shaft; 5.5 ± 0.5 mm from shoulder E of the straight axle

shaft.

Fit the bearing cone against its shoulder on the flanged axle shaft or

straight axle shaft using a suitable tool.

Lightly smear the bearing cone (7) and the lips of the seals (5) (11)

with bearing grease. Protect the seal lip (11) by temporarily masking

the splines on the axle shaft with a flexible protection. Insert the

prepared axle shaft into the trumpet housing fitted with the seal (11)

and the bearing cones (8) (12), positioning the three lips of the seal

(5) towards the outside of the trumpet housing. Refit: bearing cone

(13); tab washer (16); planet carrier (25). If necessary, shim the

tapered roller bearings; trumpet housing assembly.

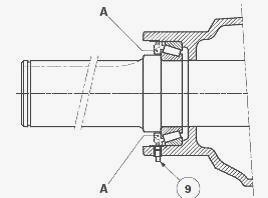

Temporarily replace the plug (9) with a grease nipple. Partially fill

cavity A with BP Agricharge grease or equivalent. Remove the grease

nipple. Screw in the plug.

Massey Ferguson 6465, 6480, 6490 - Shimming the tapered roller bearings

of the axle shaft

If the following parts are to be replaced, the shimming of the tapered

roller bearings on the axle shaft must be checked or carried out: the

flanged or straight axle shaft (2); the tapered roller bearings; the

trumpet housing (10); the tab washer (16); the planet carrier (25). The

preload shimming of the tapered roller bearings on the axle shaft is

carried out using shim(s) (26) fitted between the end of the axle shaft

(2) and the tripod washer (27). In order to correctly shim the tapered

roller bearings, fit the trumpet housing in a vertical position.

Preparing for shimming

Fit: bearing cone (13); tab washer (16); planet carrier (25). Shim(s)

(26) with a thickness greater than the space between the end of the axle

shaft (2) and the mating face of the tripod washer (27) on the planet

carrier. This should give a temporary clearance J.

Temporarily lock the M20 screw (28) at: 374 Nm (tractors fitted with

GTA1040 transmission); 410 Nm (tractors fitted with GTA1540

transmission).

Shimming

Tap the rim of the planet carrier with a plastic hammer while turning

the trumpet housing by several turns. Fit a dial gauge on the trumpet

housing (10) with its feeler pin positioned near the centre of the

planet carrier (25). Set the dial gauge needle to zero. Using suitable

levers, move the planet carrier vertically. Measure clearance J

indicated on the dial gauge. Repeat the step several times. Calculate

the average of the clearance J readings.

Reduce the shim (26) thickness according to value J + (0.02 to 0.12) to

obtain a preload P1 = 0.02 to 0.12 mm. If possible, shim to the maximum

tolerance.

MF 6465, 6480 Tractor -

Definitively fit the tripod washer (27). Lightly smear the thread of the

M20 screw (28) with Loctite 270 or equivalent. Tighten this screw to a

torque of 374-506 Nm.

MF 6485, 6490 Tractor -

Definitively fit the tripod washer (27). Tighten the M20 screw (28) to

410 Nm. From the three possible lock washers, select the lock washer (1)

which will be fitted definitively. Replacing a stud on the flanged axle

shaft. If necessary, remove the wheel from the relevant flanged axle

shaft. Drive out the defective stud. Clean the new stud and its housing

in the flange. Lightly smear the ribbed part of the new stud with

Loctite 270 or equivalent and fit it using a bronze drift and a suitable

hammer.

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF FRONT END LOADERS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS MAINTENANCE |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS TROUBLESHOOTING | ||||

| 1652 | 1749 | 2620 | 2725 | 2805 |

| 3050 | 3120 | 3640 | 3709 | 4245 |

| 4455 | 5320 | 5455 | 5613 | 6150 |

| 6280 | 6480 | 6615 | 7618 | 7720 |

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS 130

130 133

133 145

145 155

155 158

158 165

165 175

175 185

185 188

188 230

230 254

254 254S

254S 284S

284S 294

294 353

353 290

290 362

362 375

375 390

390 398

398 399

399 590

590 690

690 1010

1010 1030

1030 1020

1020 1150

1150 2620

2620 2640

2640 2645

2645 1540

1540 2660

2660 3065

3065 3095

3095 3650

3650 3680

3680 4255

4255 4355

4355 4370

4370 3630

3630 3635

3635 4245

4245 4445

4445 4609

4609 4710

4710 5435

5435 5475

5475 5610

5610 5711

5711 6150

6150 6170

6170 6180

6180 6270

6270 6290

6290 6445

6445 6499

6499 6614

6614 6713

6713 7465

7465 7495

7495 7614

7614 7622

7622 7715

7715 7726

7726 8210

8210 8270

8270 8650

8650 8727

8727 GC1705

GC1705 1464 Loader

1464 Loader 1466 Loader

1466 Loader 1040 Loader

1040 Loader 1070 Loader

1070 Loader 905 Loader

905 Loader 906 Loader

906 Loader 915 Loader

915 Loader 916 Loader

916 Loader 921 Loader

921 Loader 926 Loader

926 Loader 931 Loader

931 Loader 933 Loader

933 Loader 936 Loader

936 Loader 938 Loader

938 Loader 939 Loader

939 Loader 940 Loader

940 Loader 941 Loader

941 Loader 945 Loader

945 Loader 946 Loader

946 Loader 948 Loader

948 Loader 949 Loader

949 Loader 950 Loader

950 Loader 951 Loader

951 Loader 955 Loader

955 Loader 956 Loader

956 Loader 958 Loader

958 Loader 960 Loader

960 Loader 961 Loader

961 Loader 965 Loader

965 Loader 966 Loader

966 Loader 968 Loader

968 Loader 975 Loader

975 Loader 976 Loader

976 Loader 978 Loader

978 Loader 985 Loader

985 Loader FL.3114 X

FL.3114 X FL.3419 X

FL.3419 X FL.3522

FL.3522 FL.3615

FL.3615 FL.3619

FL.3619 FL.3817

FL.3817 FL.3819

FL.3819 FL.3823

FL.3823 FL.4018

FL.4018 FL.4121

FL.4121 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader FL.4125

FL.4125 FL.4227

FL.4227 FL.4124

FL.4124 FL.4220

FL.4220 FL.4323

FL.4323 FL.4327

FL.4327 FL.4621

FL.4621 FL.4624

FL.4624 FL.4628

FL.4628 FL.5033

FL.5033 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader 1010

1010 1020

1020 1030

1030 1035

1035 1040

1040 1045

1045 1080

1080 1085

1085 1120

1120 1125

1125 1140

1140 1160

1160 1165

1165 1180

1180 1190

1190 1205

1205 1210

1210 1215

1215 1220

1220 1225

1225 1230

1230 1233

1233 1235

1235 1240

1240 1260

1260