________________________________________________________________________________

Massey Ferguson 6465, 6480, 6485 - Rear PTO

Massey Ferguson 6465, 6480, 6485 - Rear PTO operation

The housing installed to the rear of the GPA40 rear axle contains all

the rear mechanical power take-off components. These components rest on

the tapered roller bearings, the bearing cups of which are on the rear

PTO housing and its removable compartment and fitted freely and firmly

respectively.

Profile P of the 1000 rpm gear train teeth (driving and driven gears)

differs according to the type of tractor and the transmission equipment

fitted: Power Boost. The rear PTO is independent for MF 6465, 6480,

6485, 6490 tractor except for the Ground speed PTO version, which uses

the tractor's forward speed for operation. The Ground speed PTO is

fitted to tractors as an option.

The rear PTO can be divided into four sections:

1. Clutch - The clutch is located on the upper PTO shaftline and at the

front of the centre housing. It is supported by two ball bearings fitted

in a support mounted on the centre housing.

2. Upper shaftline - The upper shaftline of the rear PTO transmits the

engine speed to the driving gears located inside the rear housing of the

PTO via the clutch and a series of three shafts. The tapered roller

bearings supporting - the driving gear shaft are shimmed with a

clearance using shim(s) inserted between the front bearing cup and the

removable compartment.

3. Lower shaftline - The lower shaftline of the rear PTO is supported by

two tapered roller bearings fitted respectively in the rear PTO housing

and in the removable compartment. The tapered roller bearings are held

in position by a nut screwed onto the front end of the output shaft. The

preload shimming of the tapered roller bearings is carried out using

shim(s) inserted between the front bearing cup and the removable

compartment. The output shaft is sealed by a lip seal fitted into the

rear PTO housing. The output shaft is fitted with an interchangeable end

fitting which may be: of varying length; fitted with 6, 20 or 21

splines. The specifications of the output shaft depend on the type of

implement to be driven and on the rotational speed to be observed.

4. Power take-off brake - The rear PTO is fitted with a brake housed

inside the rear housing opposite the 1000 rpm driven gear. The rear PTO

brake gradually slows down the output shaft inertia until it stops

completely when the rear PTO clutch is disengaged. It is also used to

immobilise the gear trains (driving and driven gears) to prevent the

"drag" effect.

Massey Ferguson 6465, 6480, 6485 - Lubrication of the rear PTO

components

The clutch - The parts inside the rear PTO clutch are lubricated under

pressure via a pipe located above and in front of the centre housing.

The upper shaftline - An external pipe carries the lubrication oil under

pressure to the upper shaftline of the rear PTO. The flow of oil to the

driving gears and the tapered roller bearings is controlled by two

restrictors and an oil deflector located respectively in the rear

housing of the PTO (power take-off) and in the upper shaftline.

The lower shaftline - The lower shaftline of the rear PTO is supplied

with pressurised oil carried by a pipe to the front end of the output

shaft. This oil lubricates the rear bearing and the splines of the

output shaft driven gears.

The power take-off brake - The PTO brake is not lubricated under

pressure. Just the splashing of oil from the rear PTO housing is

sufficient to lubricate the friction washer, which is in contact with

the machined face of the 1000 rpm driven gear when the rear PTO (power

take-off) line is locked.

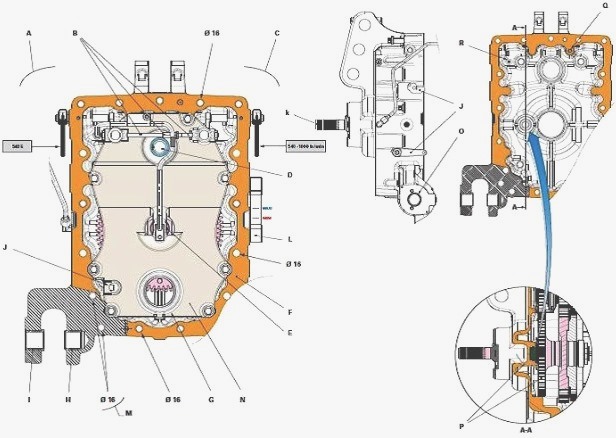

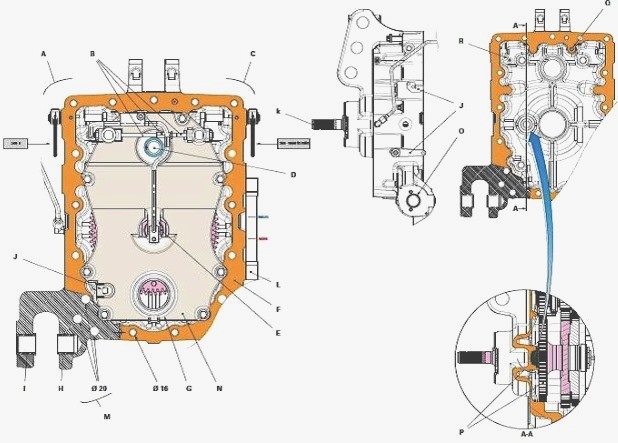

Massey Ferguson 6465, 6480, 6485 Rear PTO - Layout of the main components and

kinematics

MF 6465, 6480 Tractors installed with GTA1040 transmission

MF 6485, 6490 Tractors installed with GTA1540 transmission

The lower fixture of the rear PTO housing on MF 6485, 6490 tractors

installed with GTA1540 transmission is reinforced by fitting six 20 mm

diameter screws instead of the four 16 mm diameter screws used on MF

6465, 6480 tractors fitted with GTA1040 transmission.

Parts list: A - 540E control mechanism, B - Interlock

mechanism/adjustable sleeve assembly, C - 540-1000 rpm control

mechanism, D - Upper PTO shaftline, E - Lower PTO shaftline, F - Rear

housing of the PTO (power take-off), G - Ground Speed PTO shaftline (optional), H -

Smooth ring, I - Shouldered ring, J - Ground Speed PTO control mechanism

(optional), K - Interchangeable end fitting, L - Transmission oil level

gauge, M - Rear housing standard fixing (1040), M - Rear housing

reinforced fixing (1540), N - Removable compartment, O - Fixing for

linkage effort sensor, P - PTO brake mechanism and 1000 rpm driven gear,

Q - Pin, R - Restrictor D=1 mm

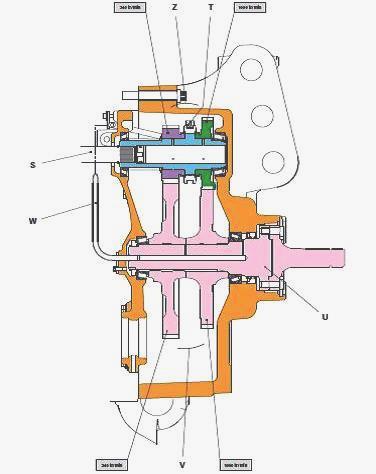

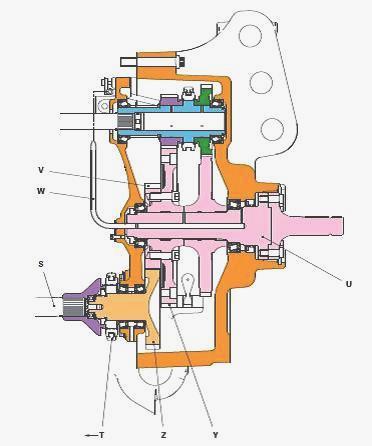

2-speed PTO with coupler control

Parts list: S - Power take-off driving shaft, T - 540 and 1000 rpm speed

selection coupler, U - Output shaft with interchangeable end fitting, V

- Driven gear train, W - Lubrication pipe, Z - Driving gear train

Kinematics

The 540 and 1000 rpm driving gears of the upper shaftline have spur cut

teeth and are constantly meshed with the respective 540-1000 rpm gears

of output shaft U. They drive the output shaft at a speed of 540 or 1000

rpm depending on the position of selection coupler T.

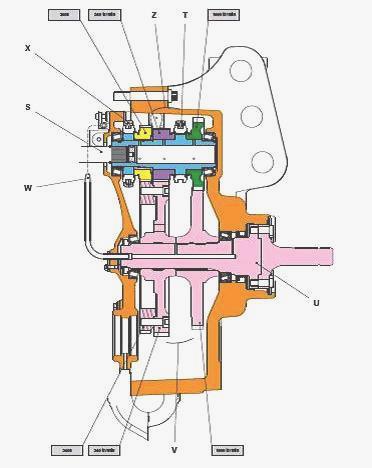

3-speed PTO with coupler control

Parts list: S - Power take-off driving shaft, T - 540 and 1000 rpm speed

selection coupler, U - Output shaft with interchangeable end fitting, V

- Driven gear train, W - Lubrication pipe, X - 540E selection coupler, Z

- Driving gear train

Kinematics

The 540-1000 rpm and 540E gears have spur cut teeth and are constantly

meshed with the respective 540-1000 rpm and 540E gears of output shaft

U. They drive the output shaft at a speed of 540-1000 rpm or 540E

depending on the position of selection couplers T and X. The 540E speed

is an economic ratio. It is obtained via an additional gear and a

coupler fitted to the front end of the driving gear train. When

selection coupler X is engaged, two interlock mechanisms joined by an

adjustable sleeve prevent selection coupler T from engaging. When a

coupler is engaged, the interlock mechanisms lock the passive coupler in

neutral at the control rod locking groove.

Ground Speed PTO with coupler control

Ground Speed PTO is fitted to tractors as an option.

Parts list: S - Power take-off driving shaft, T - Ground Speed PTO selection

coupler, U - Output shaft with interchangeable end fitting, V - Driven

gear (attached to gear Y by a screw), W - Lubrication pipe, Y - Driven

gear, Z - Driving gear

Kinematics

The Ground Speed PTO driving and driven gears have spur cut teeth and

are constantly meshed. They drive output shaft U at a speed proportional

to the tractor's forward speed when selection coupler T is moved to the

left. Ground Speed PTO is activated when the 540-1000 rpm PTO is deactivated.

The rotational movement of the Ground Speed PTO is transmitted via the

rear axle pinion (crown wheel and pinion) and a gear train 4 wheel drive

(4WD) at output shaft U via a driving shaft S and two gears Z and V.

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF FRONT END LOADERS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS MAINTENANCE |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS TROUBLESHOOTING | ||||

| 1652 | 1749 | 2620 | 2725 | 2805 |

| 3050 | 3120 | 3640 | 3709 | 4245 |

| 4455 | 5320 | 5455 | 5613 | 6150 |

| 6280 | 6480 | 6615 | 7618 | 7720 |

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS 130

130 133

133 145

145 155

155 158

158 165

165 175

175 185

185 188

188 230

230 254

254 254S

254S 284S

284S 294

294 353

353 290

290 362

362 375

375 390

390 398

398 399

399 590

590 690

690 1010

1010 1030

1030 1020

1020 1150

1150 2620

2620 2640

2640 2645

2645 1540

1540 2660

2660 3065

3065 3095

3095 3650

3650 3680

3680 4255

4255 4355

4355 4370

4370 3630

3630 3635

3635 4245

4245 4445

4445 4609

4609 4710

4710 5435

5435 5475

5475 5610

5610 5711

5711 6150

6150 6170

6170 6180

6180 6270

6270 6290

6290 6445

6445 6499

6499 6614

6614 6713

6713 7465

7465 7495

7495 7614

7614 7622

7622 7715

7715 7726

7726 8210

8210 8270

8270 8650

8650 8727

8727 GC1705

GC1705 1464 Loader

1464 Loader 1466 Loader

1466 Loader 1040 Loader

1040 Loader 1070 Loader

1070 Loader 905 Loader

905 Loader 906 Loader

906 Loader 915 Loader

915 Loader 916 Loader

916 Loader 921 Loader

921 Loader 926 Loader

926 Loader 931 Loader

931 Loader 933 Loader

933 Loader 936 Loader

936 Loader 938 Loader

938 Loader 939 Loader

939 Loader 940 Loader

940 Loader 941 Loader

941 Loader 945 Loader

945 Loader 946 Loader

946 Loader 948 Loader

948 Loader 949 Loader

949 Loader 950 Loader

950 Loader 951 Loader

951 Loader 955 Loader

955 Loader 956 Loader

956 Loader 958 Loader

958 Loader 960 Loader

960 Loader 961 Loader

961 Loader 965 Loader

965 Loader 966 Loader

966 Loader 968 Loader

968 Loader 975 Loader

975 Loader 976 Loader

976 Loader 978 Loader

978 Loader 985 Loader

985 Loader FL.3114 X

FL.3114 X FL.3419 X

FL.3419 X FL.3522

FL.3522 FL.3615

FL.3615 FL.3619

FL.3619 FL.3817

FL.3817 FL.3819

FL.3819 FL.3823

FL.3823 FL.4018

FL.4018 FL.4121

FL.4121 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader FL.4125

FL.4125 FL.4227

FL.4227 FL.4124

FL.4124 FL.4220

FL.4220 FL.4323

FL.4323 FL.4327

FL.4327 FL.4621

FL.4621 FL.4624

FL.4624 FL.4628

FL.4628 FL.5033

FL.5033 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader 1010

1010 1020

1020 1030

1030 1035

1035 1040

1040 1045

1045 1080

1080 1085

1085 1120

1120 1125

1125 1140

1140 1160

1160 1165

1165 1180

1180 1190

1190 1205

1205 1210

1210 1215

1215 1220

1220 1225

1225 1230

1230 1233

1233 1235

1235 1240

1240 1260

1260