________________________________________________________________________________

Massey Ferguson 6465, 6480, 6485, 6490 - Rear PTO clutch

Massey Ferguson 6465, 6480, 6485, 6490 Rear

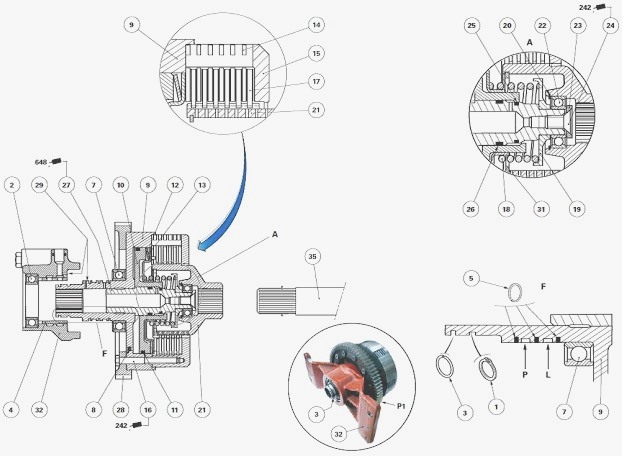

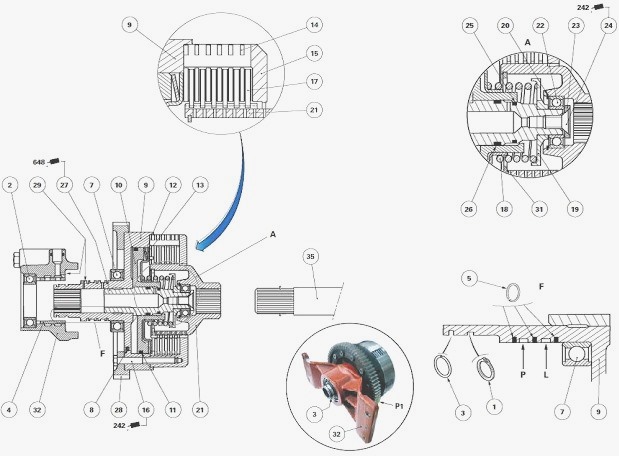

PTO clutch operation

Rear PTO clutch engagement and disengagement are controlled electrically

by a proportional solenoid valve, which is itself controlled by the

tractor's electronic system. The clutch, located at the front and in the

upper section of the centre housing, controls the operation of the rear

PTO. It is connected in rotation to the engine flywheel via a vibration

damper fixed to the flywheel and a line comprising two shafts.

It consists of a unit (9) supported by two ball bearings (2) (7) centred

in a support (32) fitted to the centre housing. The sleeve (27) supports

the ball bearing (22), the drive hub (21) and the piston (10). The

clutch housing (9) comprises: at the front, a helical gear (28), fixed

using screws, which transmits the movement to the hydraulic pumps. For

tractors equipped with GTA1540 transmission, gear P1 (28) has spur cut

teeth. It is also fixed using screws; at the rear, a bell housing (15)

with a set of discs (17) and intermediate plates (14). A sealing ring

(3) minimises leakage between the rear end of the gearbox upper shaft

and the clutch unit (9).

Clutch engaged position

The rear PTO clutch is supplied via the 17 bar (GTA1040 tractor

transmission) or 21 bar (tractors equipped with GTA1540 transmission)

low pressure hydraulic system and via a proportional solenoid valve

fitted to the right-hand hydraulic cover plate. A transfer pipe

hydraulically links the right-hand hydraulic cover plate and the clutch

support (32). Pressurised oil enters the unit (9) through hole P and

then flows to the rear of the piston (10) via an internal channel. It

pushes the piston, which compresses the discs (17) and the intermediate

plates (14). The intermediate plates are attached to the bell housing

(15) by lugs. The discs are splined to the hub (21). The movement is

then transmitted to the rear PTO driving gears via a shaft (35). When

the clutch is engaged, the PTO brake piston located in the rear housing

is at rest and releases the lower PTO shaftline.

Clutch disengaged position

If the solenoid valve is no longer supplying the rear PTO clutch, the

piston (10) is returned against the unit (9) by the spring (18). The oil

in the piston chamber is directed to the return by the solenoid valve.

The valve ball (8) leaves its seat, thus assisting the decompression of

the chamber.

Parts list: (1) Circlip (2) Ball bearings (3) Sealing

ring (4) Ring (5) Seal rings (7) Ball bearing (8) Valve (9) Clutch unit

(10) Piston (11) "O" ring (12) Belleville progressivity washers (13)

Spring support (14) Intermediate plates (15) Bell housing (16) Screw

(17) Discs (18) Spring (19) Spring seat (20) Snap ring (21) Drive hub

(22) Ball bearing (23) Chamfered washer (24) Countersunk screw (25) "O"

ring (26) "O" ring (27) Sleeve (28) Gear (29) Restrictors (31) Circlip

used for oil deflector (32) Clutch support (35) Shaft, A - Details, L -

Lubrication groove, P - Low pressure groove (17 or 21 bar), P1 - Gear

with spur cut teeth (GTA1540 tractor transmission)

Massey Ferguson 6465, 6480, 6485, 6490 -

Disassembling the PTO clutch

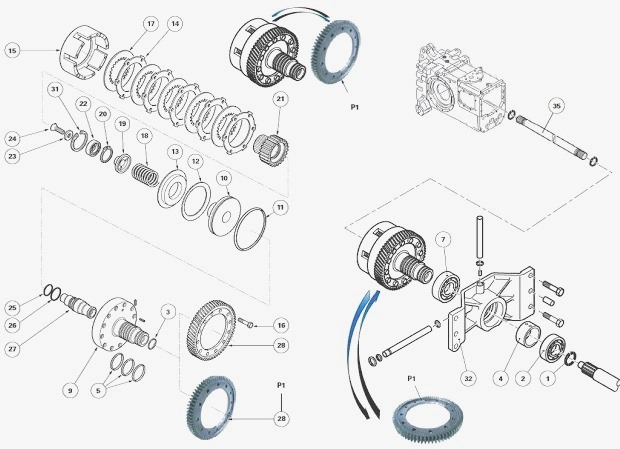

Remove the clutch. Separate the clutch from its support. Remove the seal

rings (5). If necessary, discard them. Remove the screws (16). Remove:

bell housing (15); discs (17) and intermediate plates (14); drive gear

(28). Secure the front part of the clutch unit (9) in a vice fitted with

protective jaws. Remove the screw (24), using a makeshift tool to hold

back the spring (18). Remove the chamfered washer (23).

Gradually release the spring (18) using the tool. Remove: hub (21); seat

(19); spring (18); support (13); Belleville progressivity washer (12).

Remove the piston (10) by firmly striking the clutch unit against the

wooden edge of a workbench or failing that, against block of a similar

nature. Remove and discard the "O" rings (11), (25) and (26). If

necessary, remove the circlip (31) (oil deflector). Extract or drive

out: bearing (2) on the support (32); bearing (7) on the unit (9),

visually noting the positioning of its sealed face; bearing (22) by

first removing the snap ring (20).

Massey Ferguson 6465, 6480, 6485, 6490 -

Reassembling the PTO clutch

Clean and check all components. Replace those that are defective. Check

the clearance of the valve ball (8) by vertically and rapidly shaking

the unit (9): rattling against the unit should be heard. If removed,

press fit the sleeve (27) in the unit (9). Before fitting, the fitted

section of the sleeve (27) must be lightly smeared with Loctite 648 or

equivalent. Clean off any excess Loctite. Check that the various

hydraulic ports are not obstructed after the fitting process. Using a

press and a suitable fixture in contact with the external surface of the

bearing (22), Install the bearing up to the shoulder of the hub (21).

Install the snap ring (20).

Position the sealed face of the bearing (7) towards the unit (9). Using

a press and a suitable fixture in contact with the internal surface of

the bearing (7), Install this bearing against the unit (9). Using a

press and a suitable fixture in contact with the external surface of the

bearing (2), Install the bearing up to the shoulder of the support (32).

After fitting, check that the bearings turn correctly. Install the

circlip (31) (oil deflector). Lubricate and Install the new seals (11)

(25) (26) on the sleeve (27) and piston (10) respectively. Install the

piston using a soft hammer, checking during the fitting process that

there are no fragments of seal on its rim.

Reinstall: Belleville progressivity washer (12); support (13); spring

(18); spring seat (19). Reinstall the pre-assembled hub (21), using the

tool used during disassembly to progressively compress the spring (18).

Secure the front part of the clutch unit (9) in a vice fitted with

protective jaws. Position the chamfer of the washer (23). Position this

washer in the drive hub (21). Lightly smear the thread of the screw (24)

with Loctite 270 or equivalent. Tighten this screw to a torque of 24-28

Nm. If the clutch discs (17) have been replaced, the new discs must be

soaked for approximately one hour in clean transmission oil.

Stack the new or reused discs and intermediate plates (14), starting

with an intermediate plate against the spring support (13). Install the

discs and intermediate plates alternately until the number removed

during disassembly is reached. Reinstall the bell housing (15) and the

drive gear (28) in the correct position. Lightly smear the thread of the

screws (16) with Loctite 242 or equivalent. Tighten these screws to

25.5-34.5 Nm. Install the seal rings (5). Reconnect the clutch and its

support. Install the assembly.

Massey Ferguson 6465, 6480, 6485, 6490 - PTO

clutch removing and install

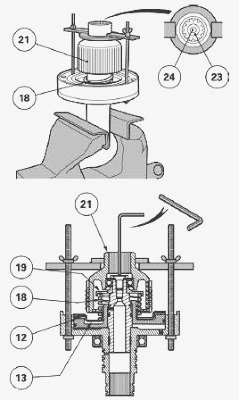

To remove the rear PTO clutch, the tractor must be separated between the

gearbox and the rear axle.

Disconnect the tractor between the gearbox and the rear axle. Remove the

right-hand hydraulic cover plate. Remove the 17-bar hydraulic pipe (MF

6465, 6480 tractor) or 21-bar hydraulic pipe (MF 6485, 6490 tractor).

This pipe is located at the top right of the mating face of the

right-hand hydraulic cover plate on the centre housing. It links the

clutch and the right-hand hydraulic cover plate.

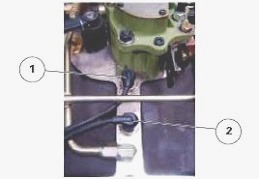

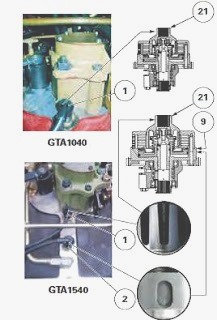

Remove: union and the transfer pipe, which are fitted above the centre

housing and are used to lubricate the clutch; sensor (1) (MF 6465,

6480); sensors (1) and (2) (MF 6485, 6490). The sensor (1) (output

speed) and sensor (2) (input speed) are located above the centre

housing. They inform the tractor's electronic system of the clutch

behaviour.

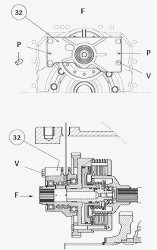

Removal

Unscrew the four M12 V screws. These screws fix the support (32) of the

rear PTO clutch to the centre housing. Using a suitable tool and the

original PTO shaft, remove the clutch complete with support (32) from

the centre housing. The support (32) is positioned on the centre housing

via two pins P. Remove: sealing ring (3); circlip (1). Separate the

support (32) from the rear PTO clutch.

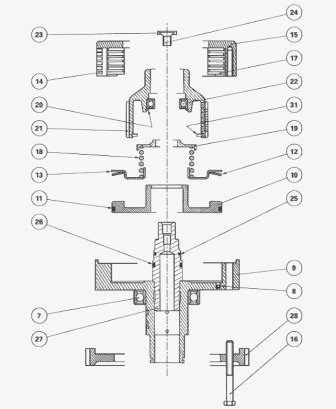

Reinstall

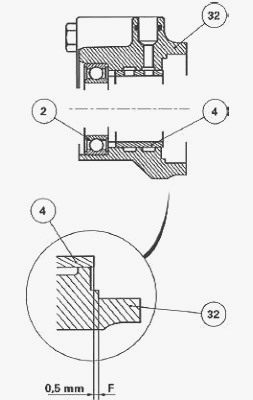

Check the bore of the ring (4) for correct surface condition. If the

diagnosis is inconclusive, replace the defective part(s). Check that the

seal rings (5) do not show any of the following: hardness; chipping;

cuts. Damage to the rings, even if it is minor, risks causing a leak

followed by a drop in pressure, which could disrupt the operation of the

clutch. If removed, using a press and a suitable fixture, Install and

position the ring (4) at a distance of 0.50 mm. This distance is

measured between mating face F of the bearing on the support (32) and

the end of the ring (4). Check that the hydraulic ports are not

obstructed.

Test Install the seal rings (5), new or reused, into the grooves of the

shaft of the clutch unit (9). Check that the seal rings turn freely in

their grooves. After this check: remove the seal rings and lightly smear

with miscible grease; definitively reinstall the seal rings; check that

the ends of the seal rings do not protrude beyond the rim of the shaft

of the clutch unit (9). Slide the support (32) onto the rear PTO clutch.

Install the circlip (1) on the shaft of the clutch unit (9). Check that

the circlip is correctly at the base of the groove.

Check that the PTO

clutch is not obstructed against its support (32) by ensuring there is a

slight clearance between the support and the clutch. Reinstall the

sealing ring (3) located at the end of the shaft of the clutch unit (9).

Check that the pins (P) are present. Install the clutch and its support

(32). Install and tighten screws V to 100-130 Nm. Reinstall: transfer

pipe and union used to lubricate the clutch; the 17-bar hydraulic pipe

(MF 6465, 6480) or 21-bar hydraulic pipe (MF 6485, 6490) located between

the clutch and the right-hand hydraulic cover plate.

Install the sensor(s) by proceeding as follows:

1) MF 6465, 6480 tractor with GTA1040 transmission - Lightly smear the

sensor thread (1) with Loctite FORM A Gasket 2 or equivalent. Tighten

home the sensor, without forcing, until its end is positioned against

the drive hub (21). Unscrew the sensor by three quarters of a turn.

Moderately tighten the nut.

2) MF 6485, 6490 tractor with GTA1540 transmission - Lightly smear the

sensor thread (1) with Loctite FORM A Gasket 2 or equivalent. Tighten

home the sensor, without forcing, until its end is positioned against

the drive hub (21). Unscrew the sensor by three quarters of a turn.

Moderately tighten the nut. Lightly smear the sensor thread (2) with

Loctite FORM A Gasket 2 or equivalent. Tighten home the sensor, without

forcing, until its end is positioned against the clutch unit (9).

Unscrew the sensor by three quarters of a turn. Moderately tighten the

nut.

Reinstall the right-hand hydraulic cover plate. Manually check the

backlash between the gear (28) and the hydraulic-pump-driven gears (Load

Sensing 110 l/min hydraulic equipment). Reconnect the tractor between

the gearbox and the rear axle. Start the engine. Check: operation of the

clutch and all hydraulic components; the tightness of the systems.

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF FRONT END LOADERS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS MAINTENANCE |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS TROUBLESHOOTING | ||||

| 1652 | 1749 | 2620 | 2725 | 2805 |

| 3050 | 3120 | 3640 | 3709 | 4245 |

| 4455 | 5320 | 5455 | 5613 | 6150 |

| 6280 | 6480 | 6615 | 7618 | 7720 |

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS 130

130 133

133 145

145 155

155 158

158 165

165 175

175 185

185 188

188 230

230 254

254 254S

254S 284S

284S 294

294 353

353 290

290 362

362 375

375 390

390 398

398 399

399 590

590 690

690 1010

1010 1030

1030 1020

1020 1150

1150 2620

2620 2640

2640 2645

2645 1540

1540 2660

2660 3065

3065 3095

3095 3650

3650 3680

3680 4255

4255 4355

4355 4370

4370 3630

3630 3635

3635 4245

4245 4445

4445 4609

4609 4710

4710 5435

5435 5475

5475 5610

5610 5711

5711 6150

6150 6170

6170 6180

6180 6270

6270 6290

6290 6445

6445 6499

6499 6614

6614 6713

6713 7465

7465 7495

7495 7614

7614 7622

7622 7715

7715 7726

7726 8210

8210 8270

8270 8650

8650 8727

8727 GC1705

GC1705 1464 Loader

1464 Loader 1466 Loader

1466 Loader 1040 Loader

1040 Loader 1070 Loader

1070 Loader 905 Loader

905 Loader 906 Loader

906 Loader 915 Loader

915 Loader 916 Loader

916 Loader 921 Loader

921 Loader 926 Loader

926 Loader 931 Loader

931 Loader 933 Loader

933 Loader 936 Loader

936 Loader 938 Loader

938 Loader 939 Loader

939 Loader 940 Loader

940 Loader 941 Loader

941 Loader 945 Loader

945 Loader 946 Loader

946 Loader 948 Loader

948 Loader 949 Loader

949 Loader 950 Loader

950 Loader 951 Loader

951 Loader 955 Loader

955 Loader 956 Loader

956 Loader 958 Loader

958 Loader 960 Loader

960 Loader 961 Loader

961 Loader 965 Loader

965 Loader 966 Loader

966 Loader 968 Loader

968 Loader 975 Loader

975 Loader 976 Loader

976 Loader 978 Loader

978 Loader 985 Loader

985 Loader FL.3114 X

FL.3114 X FL.3419 X

FL.3419 X FL.3522

FL.3522 FL.3615

FL.3615 FL.3619

FL.3619 FL.3817

FL.3817 FL.3819

FL.3819 FL.3823

FL.3823 FL.4018

FL.4018 FL.4121

FL.4121 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader FL.4125

FL.4125 FL.4227

FL.4227 FL.4124

FL.4124 FL.4220

FL.4220 FL.4323

FL.4323 FL.4327

FL.4327 FL.4621

FL.4621 FL.4624

FL.4624 FL.4628

FL.4628 FL.5033

FL.5033 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader 1010

1010 1020

1020 1030

1030 1035

1035 1040

1040 1045

1045 1080

1080 1085

1085 1120

1120 1125

1125 1140

1140 1160

1160 1165

1165 1180

1180 1190

1190 1205

1205 1210

1210 1215

1215 1220

1220 1225

1225 1230

1230 1233

1233 1235

1235 1240

1240 1260

1260